The contents

The depth of the aquifer layers in the soil can vary from 2 to 10 meters. The weight of building structures plumping the upper layers of the earth, Foundation blocks, as the knife cut into the ramifications of ground water arteries. In addition to soil water, a lot of moisture flow into the base of the Foundation with rain and melting snow.

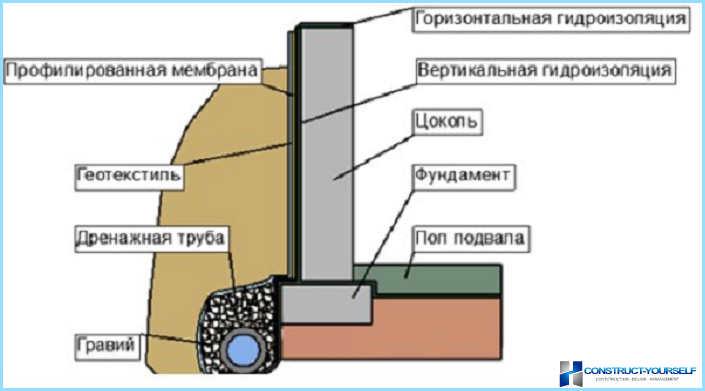

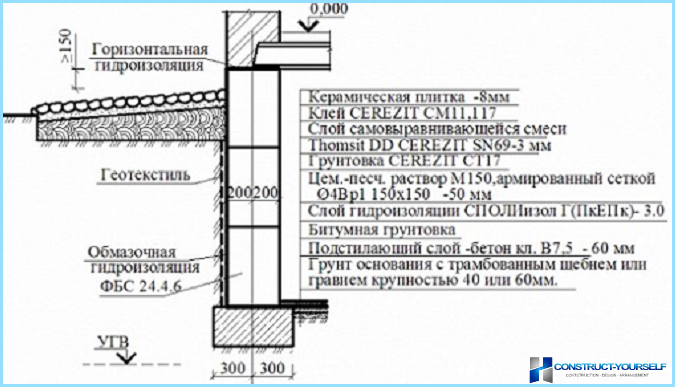

To take care of the normal waterproofing the basement needs in the partitioning step and the formation of gravel beds. Regardless of the nature of soil and level of soil water waterproofing of the Foundation must be done in conjunction with drainage. For this case, the alternatives Foundation waterproofing rolled materials just yet. Before laying out large blocks of the Foundation on the surface of the cast Foundation is laid two layers of roll material above the level of the drainage pipe.

Most of the cement compositions can not tolerate:

- High temperature,

- The impact of petroleum products and materials based on them,

- Aggressive acid and alkaline solutions.

Normal concrete is saturated with numerous microscopic air pores and capillaries. The moisture accumulates on the outside of the base of the box will penetrate into the basement, the forces of surface tension to rise through the capillaries in the dwelling.

If waterproofing is absent ↑

Depending on climatic conditions and the strength of frost in winter, water saturated layers of concrete can collapse from the bursting of the impact of ice crystals on the freezing depth of soil.

Fungus. Most often the reproduction of fungal structures and mold is possible due to the constant moisture on the walls of buildings. In addition, ground water seeping through the waterproofing defects and interblock gap, contain many active substances that promote the growth of fungus. Dust and spores produced by the fungal bloom can affect human lungs and cause rotting of wooden structures, especially of vegetables or fruit.

If the building is planned with a deep basement, and the ground abounds in solids granite, basalt, hard craggy rocks or mixed sandy soils, particular attention should be paid to the ability of the coiled material waterproof Foundation to withstand infiltration of radon. Sevenfold difference in density prevents removal of the heavy gas from the premises using a normal supply and exhaust ventilation system.

Slightly radioactive gas with alpha radiation, instantly penetrates into the lungs and is almost not excreted from the alveoli of the lower parts, irradiating the blood and lung tissue. In the list of causes of lung cancer radon is in the second position after tobacco Smoking. Not to worry with the removal of malicious gas from the premises, it is advisable to think about waterproofing with the possibility of preventing its infiltration.

The task of basement waterproofing rolled materials from radon requires coating the surface of cement Foundation blocks several layers high quality roll material which is expensive and does not always guarantee the desired result. The most effective way to stop radon is considered as the addition of a sheet of metal foil with layers of bitumen and polyester roll material. Metal really stops the radiation or leakage not only of radon but also other harmful toxic gases contained in the soil.

High stopping ability also has waterproofing on the basis of roll materials from superdense polymers with a special surface to facilitate drainage of gases and water.

Why effective waterproofing rolled materials ↑

In addition to web materials, waterproofing is easy to do using bulk bitumen composition or liquid rubber. In both cases, the waterproofing layer is applied using spray or roller and is often more like a painting of Foundation blocks, in contrast to the roll of waterproofing, thickness of the protective layer is small, its mechanical structure is more permeable to water vapor and gases. In addition, unreinforced layers very easily swell and become damaged when the temperature drops and the soil movements. In this case, they are subjected to external waterproofing special tar or bitumen mastic on rolled materials.

The most popular material for the formation of the core box foundations are precast concrete blocks or cast in place installation tape boxes. The cheapest option is the use of masonry rubble stone with a special solution. To obtain high mechanical strength of concrete mixes with such a system it is necessary to humidify a minimum of three weeks.

After the completion of the concrete frame and removing the formwork prepare the block surface for the application of waterproofing materials.

Execution of works waterproofing of the roll of material on the surface of the Foundation ↑

In the presence of building skills and getting some information from the video about Foundation waterproofing rolled materials, it is realistic to perform the work with minimal cost and a good level of quality. The key to success – use in waterproofing high-quality rolled products.

To prepare for the sticker, you must carefully level the surface of Foundation walls, remove the bumps and crevices. The best option is applying on the Foundation a special plaster on the base of bitumen emulsion based, than you can kill two birds with one stone.

First, the concrete surface is leveled and compacted, making canvas roll material for waterproofing will be on the wall of the base smoothly and evenly.

Secondly, a rolled material sticks to the base very efficiently, firmly and without bubbles. The same procedure is carried out in the preparation of the apartment walls before wallpapering.

Sticking materials on the Foundation ^ the

Basement waterproofing rolled materials with your own hands is quite easy. After alignment and priming the surface of the Foundation should be qualitatively dry. Tiny air bubbles and moisture will interfere with adhesion of the bitumen mastic roofing fabric.

As material we use high quality waterproofing roll roofing material with layered styrene-butadiene core part and a reinforcing fabric made of polyester. The inner part of the cloth has a melting film, the outer layer of waterproof closed polypropylene coating.

Gluing the canvas roll material on the vertical walls of the Foundation need from the bottom up. When marking at the bottom of the walls do a small amount of material in the 30cm to glue it with the panel base of the basement waterproofing. Further, the wall of the basement is heated with a burner or with hot liquid mastic the size of the width of the coil with a 5 centimeter margin. Mastic securing the lower edge of the coil, heat burner, place the sticker and slowly rolled the canvas up on the Foundation.

The canvas is glued from the bottom up to obtain the most intimate contact and to prevent run-off mastic from the surface of the heated portion of the basement.

Part of the mastic adhesive should be squeezed out from the overlapping panels with the adjacent sheet. Sometimes using a diagram, label roll of material when the cloth glued butt seam is welded on top of the additional strip in width of 150-200 mm. In any case, roll the pasted material should be free of creases and bubbles that can lead to breakthrough isolation.

For waterproofing of the Foundation produces a variety of different options rolled materials, the most affordable and easy is products TECHNOELASTMOST. Most of today’s mastics are manufactured on modified bitumen-based, high adhesion to cement and brick.

There are different versions of self-adhesive roll materials for waterproofing of the Foundation without the use of gluing mastics or burners. In this case, the waterproofing is rolled out and attached to the surface of the Foundation walls using polyester resin, applied by the manufacturer on the inner layer of roofing material.