The contents

- Evolution of building materials for the Foundation

- The advantages of permanent formwork over the classic

- Technology training Foundation of “home”

- Step-by-step instructions create a Foundation

- Permanent formwork velox

- Features blocks “velox”

- Technical characteristics of the boards “velox”

- Video guide to the use of wood-cement blocks

- Cladding permanent formwork

- Cottage construction

The Foundation is the Foundation of any building, it primarily depends on the durability, convenience and practicality of the structure. Since the premises started to entrust certain tasks to use the formwork. Since the first steps in this direction, it took more than a century, but the technology has undergone its own changes only in the last few years, with the advent in the construction of polymeric materials.

Classic planking is a rather bulky construction which requires considerable engineering knowledge and large time losses associated with its installation and subsequent dismantling. In recent years, in connection with rising lumber classic method does not seem optimal for the construction of Foundation structures.

Example of prefabricated permanent formwork

Evolution of building materials for the Foundation ↑

Permanent formwork is a team structure, parts of which are in most cases manufactured in an industrial environment compliance with all necessary norms, standards (Fig.1). Compounds, units of mandatory enhanced reinforced rods in the mounting grooves. The first material in a permanent form was a compound of clay and concrete solutions, reminiscent of cinder blocks, but their production is expensive. The bases on these units require additional insulation, which significantly affects the final cost of the building.

Therefore fast enough to they were replaced by foamed polystyrene, in the form of plates connected by fasteners made of metal (Fig.2). But this material is very susceptible to mechanical, thermal effects, should not be used in the construction of the Foundation of the bulky structures or high-rise buildings. The same applies to concrete formwork, which is manufactured from a mixture of cement mass and wood chips. In industrial conditions, using no cement, and magnesite, creating wwcb (Fig.3).

Blocks of foamed polystyrene

Example fibrolitovye formwork

Another option industrial casing is metal construction, paneled with plates of steklomanija. The cost of such material is low enough, it possesses good thermal and sound insulation properties, but, and this is very important, can not withstand large loads and may be used only for internal partitions.

The advantages of permanent formwork before the classical ↑

Permanent formwork for the Foundation gives a huge gain in time, as the dismantling process is absent, and the installation takes much less time than classic. Easy installation allows to quickly create the Foundation of any configuration without involvement of large number of specialists. Besides permanent formwork of expanded polystyrene makes it easy to lay the necessary communications within the plates and not worry about additional noise, insulation.

Polymeric materials are well tolerated temperature drops, so you can use them in any season without worrying about the quality of the concrete. The estimated time of the Foundation based on such materials more than eighty years (Fig 4).

An example of the cottage, the Foundation of which was executed with the aid of polymers

Technology training Foundation in the “home” ↑

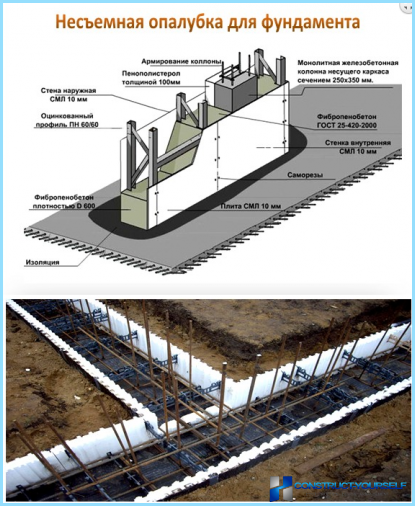

In order to minimize construction costs can all be done without the involvement of specialists. Permanent formwork with their hands possible, if you understand the structure (figure 5).

Construction of permanent formwork for the Foundation

The figure shows the pieces necessary to create a quality Foundation in the use of modern polymer materials.

Step-by-step instructions create a Foundation ↑

First need to dig a trench around the planned area. Depth should not exceed the height of the freezing of the soil (Fig. 6).

Preparation of trenches for the installation of polymeric materials

Stamped on the bottom of trenches necessary to lay the drainage, often use sand-gravel mixture. Next, you need to mount the polystyrene blocks to hold them together by spacers (Fig. 7).

Mounting blocks polymer formwork

For additional strength in the slots is possible to attach the armature, which will enable the Foundation to carry heavy loads.

In the next stage, fill the space with concrete, let it harden (Fig. 8)

Concrete is poured into permanent formwork

It is important to pay attention to another point. Before pouring concrete you should be very careful to make measurements and leveling pad under the base as permanent formwork cannot be “trimmed” after hardening of a solution. If during the installation an error was made, then eventually the whole structure may have a large slope, which is unacceptable in the construction of dwellings or industrial buildings.

Permanent formwork velox ↑

The author of one of the most famous and popular of formwork technology is a firm of Austria “Velox Werk”. The engineers of this company developed a wood-cement Board permanent formwork for rapid construction of warm houses, homes, offices and other buildings. Materials produced by the plant of the Austrians sought after the world over and firmly holding the leading positions on the market of construction materials for the Foundation.

Features blocks “velox” ↑

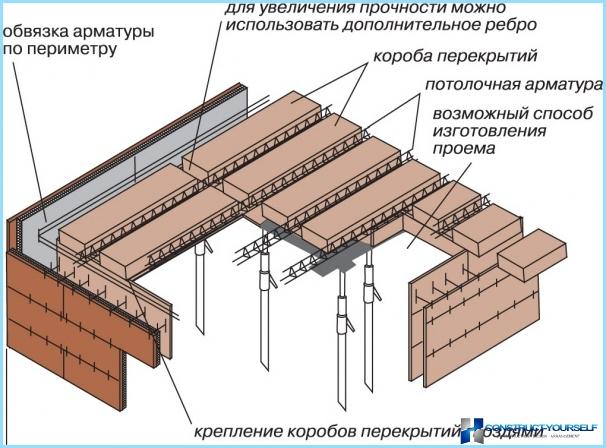

Blocks “Velox” is made from shavings of wood, pre-treated with mineral mortar, and cement. To create a thermal effect on the outer plate is attached to the Styrofoam. Thanks to this structure, the walls of buildings erected do not require installation of insulators. General construction technology the construction of buildings can be seen in Fig. 9

The Design Of The “Velox”

Technical characteristics of the boards “velox” ↑

Plates produced in the following sizes: 2000х500 mm, thickness 75, 50, 35, 25 mm. Which allows to meet the most varied imagination and requirements of the client. High insulation, low thermal conductivity still causes a high demand for materials of this company.

A cross-section of the finished wall, are made on the basis of technology “velox” is a concrete core, polystyrene and wood-cement wall. Their thickness is quite small, so they can be built on a strip Foundation, which can easily cope with their weight.

The slit plate “velox” on a strip Foundation

Monolithic formwork enables to create various elements of the future house: soffits, lintels, floors, and any curvature and size, which allows in the shortest possible time to the building. The weight of the plates is so small that they can be lifted without special arrangements. The walls of the “Velikovsky” blocks are easily treatable, making it easy to change the interior appearance of the premises. They are not afraid of moisture, absorb sound, keep warm.

Video guide to the use of wood-cement blocks ↑

On the Internet a huge number of videos on the technology of construction of houses on the basis of technology ” Velox “. But often it’s more advertising than really useful information that will bring concrete benefits in the use of these materials.

In the video you can not only get a General idea of the products of the Austrian company, but also to a lot of useful information about the direct use of locally produced building materials. The results of the use of the boards “Velox” was so impressive that many customers just need to use in the construction of their future home materials from this company.

Cladding permanent formwork ↑

Facing formwork consists of two textured panels with applied decorative. They are made of sand concrete with additives of plasticizer, securely fixed at a certain distance by means of ties. That is, this facing block is ready for filling with the concrete mixture for rapid setting wall of any rooms. The size of such formwork standard 220 to 500 mm.

The distance between the plates is adjustable depending on a necessary thickness of the walls: 300, 250 and 140 mm. load-Bearing walls usually must be 250-300 mm, and 140 mm used for internal partitions of industrial facilities.

The scenery on the facing plates can be used in variety from the “wild stone” to coloring in the style of “fantasy”, it all depends on the desires and capabilities of the client.

Cottage construction ↑

Fashion trend in high-speed construction of small houses is gaining momentum all over the world. Absolutely everything construction company focused on building cottage projects, is recommended for laying the foundations for the use of permanent formwork.

Moreover, the designs of the houses are so different that will satisfy the demand of the most demanding customer. It can be as small summer houses with an area up to fifty square meters, and luxury residences more than three hundred mTwo. They all meet the highest standards, features a huge construction speed.