The contents

- What can be useful for viewing hole?

- Advantages and disadvantages of having an inspection pit in the garage

- Construction of inspection pit

Properly a pit in the garage is a great helper for drivers, it is possible to make minor repairs and conduct preventive maintenance or diagnostic activities without any cost. She quickly becomes an important part of the structure and its main advantage.

In our country the presence of inspection pits are able to evaluate almost every car owner, and therefore the construction of a garage it is often the first plan. What is the benefit of a viewing hole made by your own hands how to design and build? And whether it Supplement already in the building?

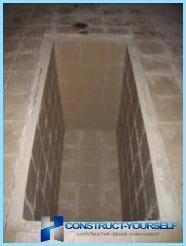

Pit out of bricks

What can be useful for viewing hole? ↑

The answer to this question is obvious – pit need for easy maintenance of the vehicle. Some lovers of themselves without the help of the wizard, make the most complicated surgeries, pitching in his garage a small STO.

Others habitually turn to the experts in the technical centers, but they can’t deny the usefulness of an inspection pit. On the roads and then there are situations in which there is a desire to return home to inspect the bottom of the car. The bumps and potholes of generous proportions occur daily, and after each unpleasant strike hardly convenient to go to the mechanic.

But in their garage in a calm atmosphere, without Queuing and at convenient time easy to check whether there is serious damage to the machine. And that pit gives you the opportunity of such examination, not to mention practical work. It gives access to:

- suspension;

- the bottom and its protection;

- muffler;

- transmission;

- the sump;

- the exhaust pipe.

Also, thanks to this construction it is possible to independently change the oil, but this procedure in the Studio is quite expensive.

pit tiles

Advantages and disadvantages of having an inspection pit in the garage ↑

At first glance, the presence of a pit in his garage is a big plus, but there are nuances you should be aware of in its arrangement. The advantages of the solution include the ability to carry out inspection of the above parts of the car, without the help of professionals. It’s simple, free, and many car owners even wonder.

Further, repair and maintenance without professional mechanic allows you to save quite a large amount. If you calculate for a year, how much it costs in the workshop oil changes and other actions, the benefit becomes obvious. Yes, and the repair skill will be more useful.

Besides if the pit is spacious enough, it is often store repair kits and spare parts for the car. This is especially true for the small area of the garage where there is a shortage of free space.

What might turn up such a useful area? The main danger during the construction of the garage with a pit are located close to groundwater. In General, the excess moisture is the enemy of the car, as if in the pit poorly made waterproofing, even in the absence of flooding, the water will accumulate on the walls of the structures due to temperature changes in cold season.

the water in the pit

However, it should be noted that the lack of a viewing hole in the case, when it is made with the violation of construction technologies and without taking into account engineering-ground features of the site.

Construction of inspection pit ↑

Whether it is at the Foundation of the future of the garage or in the ready room, the stages of construction of the same. First there is a preparation and marking the holes, then trim it and communications. It’s not that complicated, but each step requires careful execution with knowledge of some of the subtleties.

First and foremost, you need to know the level of groundwater at the site to be developed. It needs to be at least 2.5 metres in order to build it was justified, and the test is best done on your own, simply drill as deeply as possible a hole in the ground at the construction site. You can also interview neighbors who already have in their garages, basements or pits.

What should be the sizes? ↑

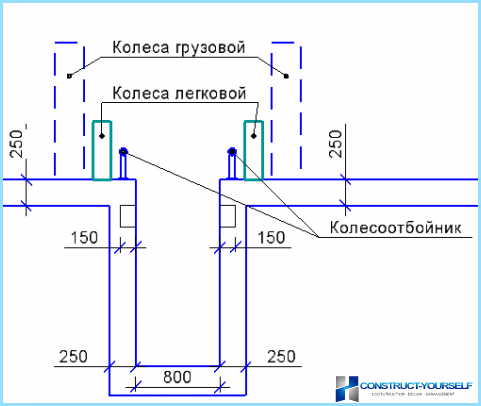

The first important step is marking the width of the inspection pit. She needs to be comfortable but not complicate movements of the car in the garage. The experience of many builders agree that it is about 70 cm, to which we can add another 5-10 cm.

A more complex issue is determining the length of the structure. It should not be less than two meters, otherwise the whole point of design is changing, however, its increase can be very useful when used correctly. If you make stationary stage, their length must also be added to the minimum.

However, to stretch it over the whole garage is not only financially beneficial but also harmful. Well, if the room is large and the pit is just going to be on the place where getting a car is another way to protect the bottom from condensation.

It is important to remember that the final size of the indentations will be less than the draft through the layers of finish and putting some walls. Therefore, at the stage of excavation to the proportions of the added thickness of the walls and floor, and “deepen” in accordance with this.

The depth of the pit should be user growth and clearance to work is 15-20 cm to the top of the pit. Better to make it deeper, because to do wood flooring on the floors is quite easy. If the same error will result in the need to constantly Bang my head on the bottom of the car, the whole building would lose its meaning.

If you build a pit for a truck, its proportions change. The distance between the wheels of large cars of different models are very different, so the basis is the size of your own car. The pit should be 30-40 cm narrower than this figure. If it is less, to reach to all nodes of the truck will not work.

If the pit is needed for maintenance and the cars and trucks, its width should be averaged. For example, the width for one car is 80 cm, and 120 cm for the other In this case, the required size of the pit is one meter, although this will complicate maneuvering on the car.

The main stages of construction ↑

Construction of inspection pit their recalibrated several stages:

- the layout of the site;

- the digging of the trench;

- laying of waterproofing;

- the arrangement of the floor;

- display of walls.

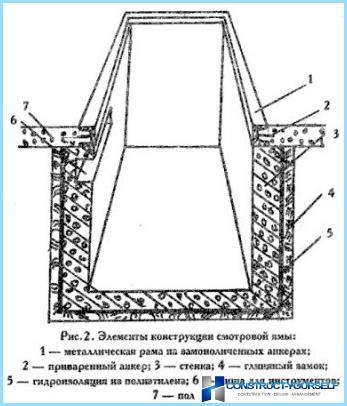

Elements of design inspection pit

In order to make the correct markings on the parcel will need to choose a building material for walls. If you selected the brick, the width of the masonry will be about 12 cm (in bricks different brands and sizes differ), and then width and length increase by 24 cm If the walls are cast, the thickness of 20 cm, that is, to the common parameters, it is necessary to add 40 cm.

Excavation is done manually, as the proportions are quite small. The walls and floor after excavation need to align as closely as possible, it will simplify further action.

The elements waterproofing

Still many people use as a waterproof layer polyethylene, however, are more durable polymer membranes or bituminous materials. If the garage is on a rather dry soil, it is possible to take a liquid waterproofing that is applied with a brush, and then freezes.

Floor sufficient concrete fill with the thickness of 7-8 cm, but the quality of the mixture must be high. Before installation of waterproofing material to conduct sealing of the floor with gravel. This layer of stone a few centimetres is laid out on the ground and hammered him with a special device – “the rammer”.

Then as the armature is placed on the floor a piece of steel mesh of the required size. The pouring is conducted at a fast pace. Since it will take quite a lot of material to make the required amount of mix in one go is unlikely. Therefore, the work should be done quickly, so the concrete has stiffened one even layer.

After the floor hardens and becomes suitable for use, conduct the reinforcement of the walls. It is often used the same mesh, just lay out layers. After the reinforcement is constructed the first layer of the formwork is filled with concrete. It is most convenient to work in three stages, by selecting and clearing on each of the casing boards. By the way, their quality can also be excellent, because after work from good wood to make shelves for garage.

Important details when constructing inspection pit ↑

There are a number of nuances that are worth paying attention to in the course of work. So, even after excavation it is important to lay in the pit walls are several niches, which then become shelves for a handy tool. A good idea is to bookmark several of inclined cylindrical recesses, in which you can then place the lights.

Further, the observation hole can be and warm. When the walls of the garage, the temperature drops to at least -10, to work in an isolated building is much nicer. You can use the Styrofoam plates that are simply planted on special glue. So reduced and the amount of condensate on the walls and the bottom of the car.

The edge of the observation pit is to decorate with iron or wooden area of small size. This is an additional stiffener for the building, and a stop for the wheels of the vehicle, which does not allow her careless driving fail.

The final touch will be the cover for inspection pit, which is collected from the boards. It protects the person from falling into a pit, and the bottom of the car from moisture, which can condense even with the most careful treatment of the walls and floor of the pit. Often the cover is difficult to raise, so the following is a simple and original solution structure suitable handle.

The stages of construction of inspection pit with photo ↑

Layout dimensions for works land works.

Digging.

Laying of waterproofing.

,

Fill the floor with concrete.

The construction of walls from a brick.

Or fill the walls with concrete.

Fine finish.

Normative documents on construction of the observation pits ↑

- TKP 45-3.02-241-2011 (02250) SERVICE STATION TRANSPORT VEHICLES;

- ONTP-01-91 “all-Union norms of technological design of road transport enterprises”;

- VSN 01-89 “Enterprise for service of cars”;

- MGSN 5.01-94 “cars”;

- GOST 12.1.005-88 “General sanitary-hygienic requirements for working zone air”.