The contents

How to choose polycarbonate for a greenhouse or how to select a greenhouse from cellular polycarbonate – these are the two questions that are most likely to interest customers, who decided to build their own greenhouse room. However, the market has become so many manufacturers of polycarbonate, which any buyer begins to get lost at the sight of their number.

The main selection criteria in this case is frame and covering.

The frame of the greenhouse ↑

Greenhouse polycarbonate panel should have a sturdy frame, then she will be able to stand and more than a dozen years. But if the frame is weak, then at the first serious gust of wind or heavy snowfall it just broke into pieces.

Frame greenhouses made from the following materials:

- tree;

- steel;

- plastic;

- light alloys.

The wooden frame is the most environmentally friendly option, but, unfortunately, without special treatment from rotting it rot completely. All this wood can SAG and break.

Frames of plastic and light alloys look nice, have little weight and for them just to care, but without a solid Foundation they can not be set. These greenhouses will be afraid of strong wind and snow, as they can simply crumble under the weight of.

The steel frame is not afraid of strong winds or heavy snow. It is easy to assemble and it is durable as galvanized steel.

Portable arc under the force of gravity can break and damage the whole building.

The distance between the arcs depends on the type of polycarbonate, and each manufacturer specifies in the instructions of the required distance.

Pre-plan location of air vents and doors to reset the temperature during the heat.

The shape of the glasshouse ↑

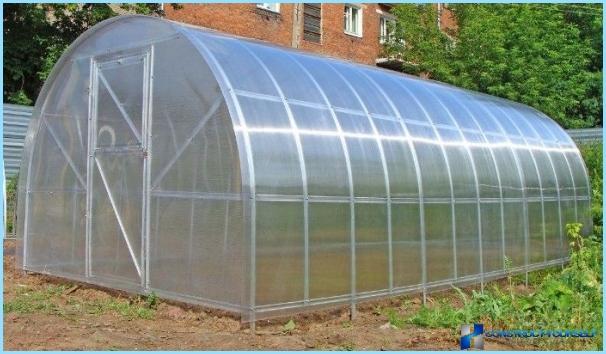

The best shape for the greenhouse is considered to be arched.

The advantages of the arched form:

- it will slide down snow and water;

- it is easier to mount, since there are no sharp angles;

- spherical greenhouses retain heat better than anyone.

The Foundation ↑

To do the Foundation or not, each user decides for himself. If the Foundation, the greenhouse will be completely tied to one place. In addition to the construction of the Foundation requires additional costs.

Modern greenhouses from polycarbonate can do without Foundation. As special steel stakes nailed directly into the ground and these are attached to the greenhouse arc.

Basics of cellular polycarbonate ↑

What is polycarbonate and how to choose the right polycarbonate for greenhouses – let us examine these two points in more detail.

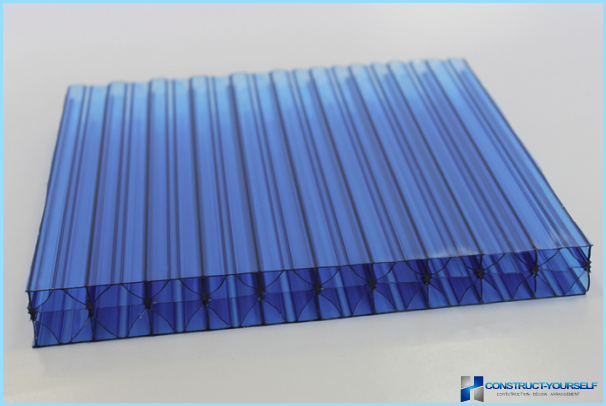

Polycarbonate is laminated plastic with a strut, which is called honeycomb. Jumper significantly affect the reliability of the material. The cells are located either along the sheet or wave.

The types of cellular polycarbonate for greenhouses:

- single chamber;

- two-chamber;

- Multicam;

- reinforced.

Sheets of this material are marked with a letter R. for Example, 2R – 2 is a continuous sheet of connected partitions. The letter X means reinforced construction, i.e., 2RX – reinforced one-part sheet.

Now let’s talk about what polycarbonate greenhouses better.

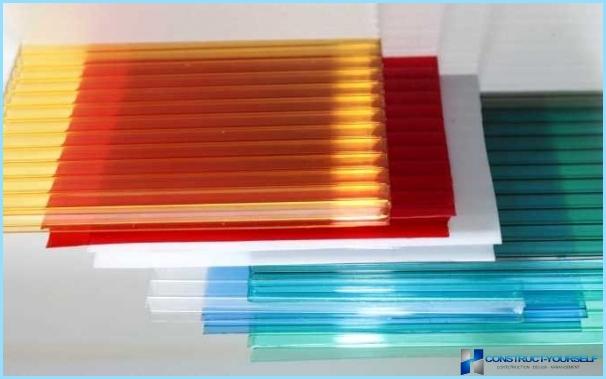

Polycarbonate is different thickness, size and color.

The thickness of cellular polycarbonate for greenhouses is in the following:

- 4 mm – suitable for shop Windows;

- 6 mm – greenhouses, canopies;

- 8 mm large greenhouses, roofs, walls;

- 10 mm for vertical surfaces;

- 16 mm – roof with a large area;

- 20 mm – balconies, swimming pools, Parking;

- 25 mm – for winter gardens, greenhouses, industrial buildings;

- 32 mm sections of the roof with a heavy load.

If you plan to use the greenhouse from spring to autumn, of a thickness of 4 to 10 mm, and if you’re going to heat it, more than 15 mm.

The most popular sizes of polycarbonate for greenhouses is:

- 2,1?2 m;

- 2,1?6 m;

- 2,1?12 m.

Characteristics of the material ↑

- High insulation material (even at a thickness of 4 mm, the insulation is higher than the glass twice).

- Excellent light transmission (up to 92% of sunlight).

- Protective layer from ultraviolet rays.

- Strength and impact resistance (stronger than glass and 50 times, udaroprochen 250 times).

- Easy installation, flexible.

- Durability.

- Light weight (10-15 times less than glass).

- Fire-safe and self-extinguishing, therefore, is used in many industries.

- Excellent soundproofing.

- Various colors.

Selection rules of material ↑

First, decide – what you will have a greenhouse, so it was combined with the design of your buildings.

- Before you buy learn all you can about the polycarbonate on the Internet, go to the official sites of manufacturers of high-quality material, read reviews. Only then go looking at the major outlets. Winter, incidentally, can be purchased at a discount.

- Carefully read the label on the protective film, as sellers can try to sell a lightweight version instead of the standard. If there is no marking, it means the Chinese material, and not the best production. ?Warning! Do not purchase the material without marking and without UV protection, otherwise the sunlight, he quickly destroyed.

- Take a Vernier caliper to measure the thickness instead of 4 mm, you can get a 3.5 mm and it is absolutely not suitable for our climatic conditions.

- Pay attention to the weight. A standard will weigh 10 kg, light weight about 8.5 kg.

- The panels should be efficiently Packed, no scratches, dents, swellings etc., they should lie flat and not be folded.

- The panels must be level for proper installation and marking of presence of the protective film.

If the sellers ask you to buy polycarbonate cheaper than the manufacturer sells, immediately get out of there. Because most likely it is a fake or defective material.

What’s wrong with the low-quality polycarbonate? As soon as cold weather conditions, the polycarbonate will start to darken, crack, pass respectively the water and air, that is, the greenhouse will begin to break down.

Proper installation of a greenhouse from cellular polycarbonate ↑

Before making a greenhouse from cellular polycarbonate with their hands, it is necessary to remember some important rules:

- for greenhouses it is recommended to only use transparent polycarbonate, otherwise the plants will not have enough light;

- installation of cellular polycarbonate in the greenhouse, produced a protective layer to the outside; Attention! Sheets only be installed vertically, so that the condensate flowed down.

- mounting of polycarbonate on a greenhouse doing with screws with rubber lining or with thermo washers every 30 cm.

- holes for screws should be more of them in 2-2,5 mm, distance between holes not less than 50 mm from the sheet edge;

- as polycarbonate when the temperature changes can expand and contract, it should be noted that during the overlap greenhouses cellular polycarbonate and make the gaps between the leaves and frame, but the sheet must be in the profile is not less than 20 mm.

To disassemble, in detail, how to install a frame we won’t, because design decisions in this regard are many, it just depends on your imagination. Moreover, the frames can be purchased ready-made. The main conditions for the selection of the frame we considered in the beginning of the article.

Installation of a greenhouse from cellular polycarbonate can be done with your own hands, by the way, will come much cheaper.

You can check the correct installation of a greenhouse from cellular polycarbonate in the video below.

Mounting plates to the frame ↑

- First, you must prepare the leaves. Polycarbonate easy enough to cut with a knife, but it is desirable to cut high-speed circular saws. During cutting the sheets must be fixed to avoid vibration.

- The next stage is drilling holes for the screws. Drilling is necessary between the jumpers.

- Next, it is necessary to protect the ends of the panel. For this purpose the upper end is sealed with aluminum adhesive tape (if the greenhouse is not arched), and lower – perforated, it will not allow insects and dirt to get inside, but the moisture will be able to pass. In any case, do not use the tape and leave the ends open.

- After the tape is put on the sheet end profile. Use them the same color as the leaves. They are fastened securely thanks to its design, so additional fastening is not required. In the end the profile also drilled holes for the condensation.

- Before installation the protective film it is better not to remove.

- Polycarbonate is fixed with screws or practical (preferably).

- Leaves between and aligned with a connecting profile, which, in turn, is fixed to the frame. Don’t forget about thermal expansion, leave a gap.

Care cellular polycarbonate ↑

Polycarbonate can be washed in warm water with a soft sponge/cloth, ordinary soap, or any means that does not contain ammonia, ether and acetone.

Reviews about greenhouses from polycarbonate. ↑

Anastasia:

– Polycarbonate bought my husband. As he chose, I do not know. The greenhouse is small. At the moment I have potted flowers and seedlings. It’s only the beginning of spring, and often have the window open as the temperature sometimes reaches 30 degrees! Very happy with purchase.

Xenia:

– Greenhouse for 5 years, but the polycarbonate looks like new. Due to the protection from UV rays plants are never burned! Besides, it is many times warmer, than simple harvest and grow more. Plan to buy another one.