Building a new home is always a big expense. Few can afford to build, not paying attention to the budget. This files most often have to save to fit in the budget. However, the savings should be reasonable, because in the new house will live the owner and his family. The building should be warm, dry, comfortable, pleasant to look at. How to achieve this without overpayments? In the first place – to save on the brigade staff. If the developer has the right skills, everything or almost everything you can do yourself. Also you can select cheap materials, available technologies, typical project. As cheaper to build a house with his own hands? What should we save, and where better not to risk it?

The contents

Saving starts with choosing a project. The more complex architectural forms, the more expensive the construction. It is irrational to try to reduce costs at the expense of workers, technical supervision or the quality of the materials initially selecting an expensive project.

It is better to clearly define the necessary area of the house without depriving the family, but not allowing himself the extra square meters, choose a simple shape of the roof. This will create a cozy home, fully meet the needs of the family, but without architectural «frills» — multi hipped roof, Bay Windows, columns, arches.

It makes sense to consider the option of building one – or two-storey houses with an attic.

Residential loft is much more profitable than a separate floor. The construction of the floor need more materials for walls, insulation, finishes. As for the arrangement of the attic the desired truss design, quality insulation and good roofing materials. As a result, the owner receives housing and roof at the same time

If you choose light materials and suitable technologies for the construction of walls, you can save on Foundation. Will need a less powerful design, plus the formwork can be made of substandard boards, fiberboards used.

The only thing that is undesirable to cut costs, cement it. Need to buy some quality, otherwise the strength of the design is questionable. The depth of the trench for the Foundation should also match the calculated weight of the building to avoid heavy rain, which can lead to cracks in the walls.

The most popular materials for private housing:

- brick;

- beam;

- gazoblok.

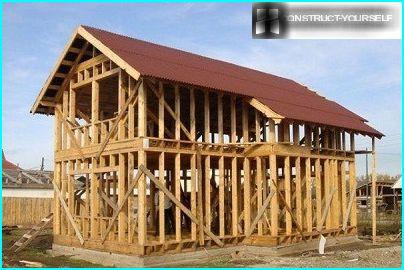

In the construction of houses and cottages are increasingly using timber frame technology. This is a promising method, allowing to build quickly and with minimal costs.

To find out what the cheaper it will cost to build a house, you have to calculate estimates for each option, because the cost of the material itself is not always an indicator of benefit. For example, the choice in favor of multi-purpose materials will help to reduce costs. The cost of hydro-and vapor barrier «two in one» cost ultimately cheaper than buying two different types of insulation.

The calculations should proceed from the fact that the finished building should be comfortable, conform to the standards for heat saving, security.

The advantages of frame construction in less time and labor costs for the construction of the building. The design is very lightweight, does not create additional load on the Foundation and does not require amplification

Option #1 – frame house construction

House on frame technology built in periods ranging from several weeks to several months depending on builds if the owner himself or hires a crew. The finished building is durable, resistant to deformations. The estimated lifetime is about 75 years.

Supporting structures convenient for subsequent plating finishing materials, because all the elements are unified. This greatly expands the range of options facing facades: on the walls you can mount the siding panel cluster, a block-house. When covering with sheet materials increases the strength of the whole structure without significantly increasing its weight.

How to collect a frame house and how much it costs the construction can be learned from this video:

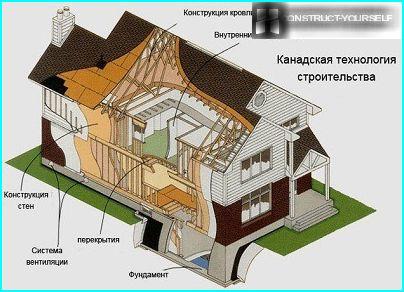

There are two main frame technology, each of which has its own characteristics.

Frame and panel. As cheaper to build a house? Gathering himself. Of course, this will require skills and equipment. Thanks to the modular construction it is possible, though you’ll need to invest a lot of time and extra money in the purchase of insulation and other materials. The frame is made of wood and is covered on the sandwich panels. Each material has to be mounted separately, which affects the timing and intensity of construction.

Karkasno-panel Board. This option is expensive, but reliable and requires less labor. A house assembled from ready-made panels are manufactured in the factory by special order. The boards are delivered already insulated and ready for Assembly. If you compare the price of panel and panel houses, the first is more expensive. However, the final cost may be identical if the Assembly of frame-panel houses invite the workers, because you have to pay all types of work separately – Assembly, sheathing, insulation, finishes.

The wooden frame is assembled already like the ready house. It only requires plating and finishing. Into the walls are still factory mounted steam – and waterproofing materials, thereby increasing the lifetime of the building

Undeniable advantages of the technology:

- Efficiency. A small weight at home is an obvious opportunity for savings on the Foundation, and short time – to pay workers. It is believed that houses built on frame technology, cost is cheaper, but in many ways, the economy depends on the area of buildings, selected materials, finishes, etc. experienced engineers Calculations show that it is advantageous if the length of the building does not exceed 20 m, and the number of storeys – 3. Often it is all about the project.

- High rate of saving. A frame house warmed up quickly and efficiently. The walls are made of materials with low thermal conductivity, allowing design holds heat well. The thickness of the wall can be 15-20 see additional benefits of timber frame houses – reduction in heating costs compared to a conventional house of the same area.

- The lack of shrinkage. Wall design durable, resistant to deformation, high rigidity, and the house does not shrink. It also has a positive effect on the timing of the construction: finishing work can begin immediately after completion of the main works. The covering made of materials that do not require additional processing, which reduces the cost of finishing.

Disadvantages or things to consider:

- To build a frame house requires special knowledge and tools. Skill builders is critical, so not every developer can handle myself, and the team will have to choose carefully.

- Wooden frames require additional processing compositions for biological and fire protection.

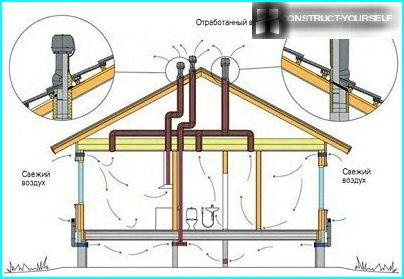

When you select the project, special attention should be paid to ventilation. Artificial materials are excellent teploizolirovat, but from the point of view of environmental safety leave much to be desired. If the house is small, it is theoretically possible to do natural ventilation, but ideally and for it it is necessary to calculate and establish the system of normal air exchange.

When assembling frame structures are not used «wet» technology. This feature is a big plus because it allows you to work at any time of the year

Leaks – one of the main advantages of frame houses, as is the key to good insulation. But it has a downside – a violation of the air. To the products of human activity, dust and other factors worsened the microclimate in the building, did not reduce the amount of oxygen in the air, it is necessary to design a high-quality ventilation system

Materials for the frame:

- Tree. Despite various types of treatment, wood is exposed to moisture, microorganisms. On average, this framework serves to 60 years and inferior to the metal counterparts in strength, lightness, resistance to destructive environmental factors.

- Metal. For manufacturing of skeletons of houses are used lightweight thermal profile. Its advantages – the excellent fire resistance, light weight, corrosion resistance. The metal parts are not subject to attacks of fungi and mold. All this can increase the life of structures up to 100 years.

What would be cheaper to build a house? The cost estimate will be a clear advantage over a wooden frame. However, if «to look into the future» and consider the higher performance characteristics of the thermoprofile, his life completely pays for the cost.

The Foundation, you can choose tile, bar or strip depending on soil type. You can save on easy to install roofing – gable or Dormer. The choice is the developer.

1 m metal frame weighs about 30-50 kg, with a shell of about 200 kg. the Small share of the finished home allows you to build on unstable ground. The profile is also used in the reconstruction of buildings with very worn load-bearing structures. Heat-saving characteristics of the profile high enough to use it to build houses in regions with harsh climate

Option #2 – construction of brick

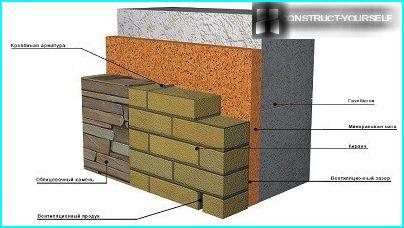

Brick is one of the most popular building materials. At home it is difficult to call cheap. The walls have to do thick, plus they require additional insulation, which leads to even more expensive designs. The weight of the house is great, so the Foundation really strong. It is made on the depth of soil freezing.

Save it difficult. The disadvantages of brick houses is attributed by a long, laborious construction. However, the durability of structures, fire safety and practicality largely pay for itself.

If you look at the prices for the erection of a neat brick house on the websites of specialized companies, it seems that the cost is small. However, even in the price of construction «turnkey» not inherent fine finish: the installation of flooring, interior doors, plumbing fixtures, etc.

If it’s all to do with your hands, then the cost should only include the costs of purchased materials. If you need to hire workers and pay them a wage. Brick building is beneficial only if the owner of the site is competently picked up the project and most of the work can be carried out by.

About the features of brick construction explained in detail in the video:

Option #3 – aerated concrete blocks

Aerated concrete block is a worthy competitor to traditional brick. The construction of this material is significantly cheaper than the construction of brick walls. The wall thickness may be less by 1/3 without loss of insulating properties. The material is lighter than brick, which allows savings at the expense of the Foundation. Additional «bonus» for the home owner – good soundproofing.

House of concrete blocks «breathing», it is not broken ventilation, because the pores through. However, for the same reason the material is not the best, in terms of waterproofing. If construction is conducted in violation of the technology, the finished design can still be purged. Need to pay attention to finishing materials.

Regarding the timing of construction, concrete house can be erected 2-3 times faster than the brick, it virtually does not shrink. To connect the blocks using special adhesives. While it is undesirable to use a normal cement mortar, because it gives thick seams that can cause the formation «cold bridges».

One of the disadvantages of gas-concrete blocks is a relatively low frost resistance, so you’ll have to take care of quality finishing. As materials you can use plaster, siding, stone

Option #4 – economical log houses

For the Builder, timber is cheaper than brick and aerated concrete blocks. If you compare brusovo and brick walls for heat-saving properties, it appears that the design of the spruce with a thickness of 220 mm and made of bricks with a thickness of 600 mm will be equally warm. Usually for building you take a bar of 200 mm, use insulation thickness of 100 mm and put a plaster coat of 20 mm.

The advantages of timber:

- efficiency;

- fast construction (building erected for a few weeks);

- simple technology;

- environmental safety;

- excellent heat insulation;

- a comfortable climate in the finished building;

- the lightness of the design.

If you choose what is cheaper to build a house with his own hands, timber – win-win. It is profitable, and the technology is simple, and it can learn almost any owner of land if he already has the skills of building business.

In the construction of houses of timber should be carefully to design the heating system and energy supply. The buildings are considered a fire hazard. Also the tree is afraid of water, and therefore requires protection from moisture and mildew

Compare prices per square meter

How and what the cheapest way to build a house with your own hands, you can see in the figures in the estimates. If the calculations come from averages (depth of frost penetration is 1.5 m, the groundwater – 2.5 m, sandy loam soil), it is possible to determine the cost of construction of 1 sq m of the house. Depending on the material the figures are as follows:

- frame construction – 875 rubles;

- brick – 2330 rubles;

- aerated – 2000 rubles;

- timber – 1900 rubles.

Additional information about the most popular materials:

It is obvious that the frame house will cost the developer less likely. Finally settled with the selection, you need to consider all features of the project of soil of the site itself. These estimates do not include payment for services of construction brigades. Hired labor is an additional (and considerable!) expense.