The contents

For finishing of facades, and as a finishing coat for interiors are extensively used plasters with different base and filler, but perform one function – create coatings that provide protective and decorative functions.

Varieties of silicate plasters ↑

Wide application due to its vapor permeability, which allows to perform high-quality insulation of external walls of buildings method «wet» insulation, received a silicate plaster for the facade, the application of which the surface of the adhesive layer of the insulating coating provides a release of warm, moist air from the building. Composition of silicate plaster is a mixture of sodium and potassium silicates with mineral fillers of different size, a variety of additives, dye and water.

For finishing of external walls of buildings with concrete, lime or gypsum base, applied silicate facade plaster, forming an attractive decorative finish which is characterized by elasticity and charge to ensure a clean surface and lack of dust. Resistance to atmospheric agents, water repellency and full of fire make this material indispensable in the finishing, including on top of the polystyrene or cellular concrete.

Silicate plaster, as the fine finish of aerated concrete, is the perfect solution to the question of external and internal decoration of the building, because good adhesion with the cellular surface of the concrete, which cannot be achieved using acrylic finishing mixture.

Produced silicate decorative plaster in the form of a ready mix that does not require dilution or compounding, but requires thorough mixing before application. The putty is sold in plastic containers weighing from 5 to 25 pounds, allowing you to buy the necessary amount of the expensive material. Depending on the fraction of mineral filler, you can get different textures with topcoat:

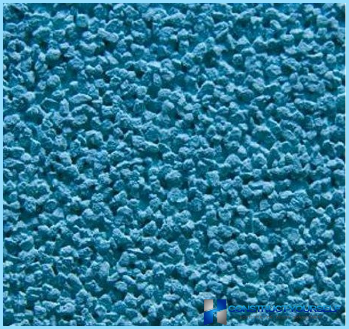

- when the amount of mineral filler, from 1 to 2.5 mm is available «kameshkovo» or «mosaic» invoice;

- mineral inclusions with a size of 2-3 mm when applied it turns the texture «woodworm».

Despite the fact that silicate decorative plaster is designed for outdoor use, it can be successfully used for interior decoration, for example, kitchen walls or as cladding balcony.

A kind of putty on a silicate basis is silicate-silicone plaster, got its name thanks to the addition to the base emulsion of silicone resin. In addition to the liquid silicone mixture includes an aqueous solution of acrylic resin, a water-repellent additive, mineral filler, modifiers and pigments.

Compared to a similar material without the addition of silicone resin, silicone and silicate decorative plaster has the following characteristics:

- the best resistance to atmospheric agents;

- a higher degree of coupling with a surface;

- increased resistance to fungal manifestations and mold;

- high mechanical resistance and elasticity.

Technology of preparation of brick walls ↑

In the performance of building external walls of sand-lime brick, before applying to it a topcoat is required the preliminary preparation of the surface, which applies a mixture of sand and binding framework. Silicate plaster on the brick is performed by applying a sand-lime mixture on pre-fixed metal or polymer mesh, the thickness of the layer is defined with a fixed beacon profiles.

Technology of plaster of external walls of sand-lime brick has the following specific features:

- before applying sand-lime putty should be thoroughly cleaning the surface with wire brush or by water-jet treatment;

- sand-lime mixture with stirring should not stick to the mixer, and if this happens, you need to add sand;

- the mixture after mixing should have a uniform structure, on the sides of the container may not be particles of lime or sand;

- before applying the first coat the brick surface should be liberally moistened with water;

- plaster is produced in several layers, followed by the alignment produced before the solution dries.

The technology is applicable if it is plaster sand-lime brick outside the building. While on top of the sand-lime layer it is recommended the arrangement of hydrophobic finishing layer, which may be silicate mass for plaster.

In that case, when we perform the internal plaster on the silicate brick, the technology application would be the following:

- pre-made sealing holes and cracks in masonry;

- the first layer is applied by spraying method, without alignment;

- the subsequent coat is applied after drying with a float, leveling the surface;

- as the material of the coating used sand-cement mixture with the addition of lime or gypsum;

- on top of the rough layer is made by applying a finishing coating, which may be silicate plaster for interior works.

Plaster walls from a silicate brick directly applied to the brick is a silicate or silicate-silicone mixture is not rational, because of the necessity of applying the layer with a large thickness for leveling the surface and as a consequence of the high cost of production works.

When finishing the interior walls with the silicate mixture, many owners over time, when the colour fades, the question arises whether it is possible to paint silicone paint, silicate plaster? The recommendations of manufacturers of silicate and silicate-silicone plasters provide the ability to update the surface with silicate paint CT 54 or CT 48 silicone. Must be completed primer surface.

Popular spackling mixture ↑

The most common and popular blends on the market of construction materials are silicate mixtures for plaster:

- Silicate-silicone plaster Weber the product from the manufacturer Weber Vetonit, characterized by water vapor permeability, elasticity, water repellency and self-cleaning effect. The material is available in three different sizes «bean», determining the surface texture and material consumption:

- fine-grained mixture with the grain size of 1.5 mm and a flow rate of 2.4 – 2.6 kg per square meter;

- medium-grained mixture with the grain size of 2.0 mm and a flow rate of 2.9 – 3.1 kg per square meter;

- coarse-grained mixture with the grain size of 3.0 mm and a flow rate of 4.5 – 4.7 kg per square meter.

- Tserezit, silicate-silicone plaster from the German manufacturer «Henkel» guarantees the following properties:

- permeability to water vapour of the air;

- UV resistance;

- resistance to fungal and mold formations;

- hydrophobicity and resistance to frost;

- the opportunity for indoor and outdoor use. Comment! One of the leaders in sales of branded products «Ceresit» is plaster silicate-silicone Cerezyme CT 174 «kameshkovaya» – being thin granular mixture with a grain size of 1.5 mm.

- Silicone-silicate plaster Kreisel (sisiputzaussen ober strukturputz) from the German manufacturer «Kreisel», guarantee German quality universal decorative ready to spray tinted facade fillings. The material is characterized by resistance to atmospheric agents, resistance to water and frost, so that can be used for exterior finish on the entire territory of Russia.

Selling silicate-silicone facade plaster in Moscow, Nakhodka or Yaroslavl can be found in stores selling building and finishing materials, and the range of specialized online stores.