The contents

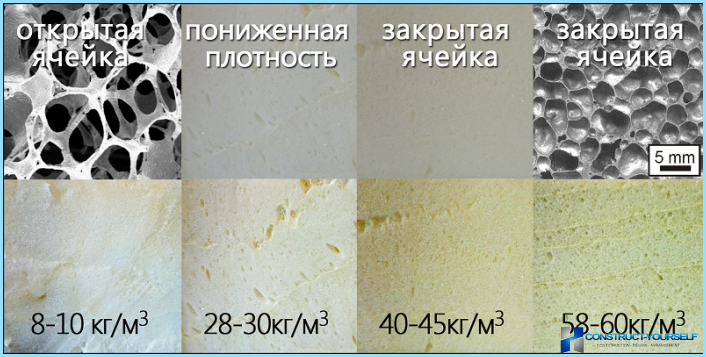

One of the chemical wonders of modern chemical science had been the invention of a new polymer, known as polyurethane. Is made from petroleum products by chemical processing. Has a cell structure in each cell are gas bubbles. By varying the proportions used of the raw materials, get polyurethane foams with various cell sizes. They differ also by the thickness of the walls of cells. The result can be soft and rigid polyurethane foams having different strength and elasticity.

The creation of this material is the merit of German scientists led by Otto Bayer. Indeed, thanks to the new technical characteristics are different from other materials many advantages, the use of which allows a wide application of polyurethane products in various fields.

Classification of polyurethane foam ↑

Types of foam depending on the strength of cells:

- the usual type;

- high hardness;

- soft and very soft type;

- visco elastic and highly elastic.

Rigid polyurethane is widely used in construction, renovation, insulation of buildings and other options. There were many researches of characteristics of polyurethane, including, for artificial aging of the material. Its service life in structures up to 50 years. For successful its application is necessary to avoid contact with organic solvents and strong mineral acids. The material is resistant to water and petroleum products.

Technical characteristics of rigid polyurethane foams ↑

Among the many foamy polymers difficult to find material that combines so many advantages:

- High thermal insulation capacity;

- Excellent noise absorption;

- Resistance to aggressive substances;

- Low moisture absorption;

- Low Flammability;

- Durable in use;

- Environmentally friendly material, safe for human.

Characterization of the thermal conductivity of foam depends on the size of the cells of which it consists. However, in comparison with other thermal insulation foam is the clear leader in terms of heat, inferior to him in this, even mineral wool.

The attenuation is determined by the thickness of the insulation layer, its damping properties and elasticity and breathability. The ability of the foam to the delay of the sound depends on the characteristics of material stiffness and frequency of the sound vibrations. For the best protection against noise is preferable to use polyurethane elastic type.

Polyurethane foam is chemically resistant, for this indicator, it is superior to polystyrene. It can withstand corrosive chemical vapors to acceptable concentrations, are not destroyed by the action of oils, spirits, gasoline, resistant to esters and ketones, diluted acids. A layer of polyurethane applied to the metal, protect it from rust. Characterization of the effectiveness of such protection varies depending on kinds of polyurethane foam.

The moisture resistance of the foam is high enough. It also depends on the recipe, which made the polyurethane foam. The higher the density, the less water absorption. If you want to increase moisture, add special substances (repellents). For example, the addition of castor oil in the composition of the foam allows 4 times to reduce its water absorption.

The characteristic of Flammability of the foam ↑

Characteristic Flammability relates to the substances with a sufficiently low degree of combustion. The use of different additives allows to increase its resistance. The change in the chemical formula the more expensive cost option, budget is an additive in the formulation of halogen or phosphorus compounds. This allows to obtain resistant to ignition materials. To improve the fire resistance, not too increasing the cost of the material, it is possible over conventional polyurethane coating, apply a small layer of fire-resistant. It would be a reasonable option for areas with high risk of fires, in particular, to separate production areas.

The density of polyurethane foams differ depending on the production technology. Materials with high feature densities up to 80 kg per cubic meter are more expensive at a cost of less density is cheaper.

Durability, according to the manufacturer, up to 30 years, although actual service life exceeds this value. American and Japanese experts explored the technical characteristics of samples of polyurethane foam used in the construction of buildings in the 70-ies of the last century. In the result it was concluded that the characteristics of samples of materials taken from the walls, from the roofs of buildings, remained unchanged. Still remained and chemical resistance, and thermal insulation technical properties.

The use of polyurethane foam ↑

Technical and environmental characteristics of the polyurethane foam after curing completely safe for human health.

The advantages of the technical characteristics of polyurethane foam as insulation for various structures can be attributed to the excellent ability of the material to “stick” to any surface, regardless of the materials from which they are made, and forms of coverage. Characteristics of the sprayed polyurethane foam can be applied to various materials: wood, glass, metal, concrete, regardless of horizontal or vertical design. In addition, the polyurethane foam is highly adhesive and easy to apply, it does not need additional securing on the surface and very difficult to handle before applying the coating.

Due to the small weight in the application of polyurethane foam does not weigh down insulated construction, construction is a significant plus. Application of polyurethane foam increases the density of the structures on which it is sprayed. Equally polyurethane foam and tolerates high and low temperatures, these characteristics make it possible to use both outside and inside premises, both residential and industrial.

Polyurethane, unlike other forms of insulation (sheet or panel variants), does not form seams or cracks that need to be further repaired. He fills all the space around the insulated design allows you to seal various inconvenient for other types of insulation space, moreover, does not require the use of additional fixation means to the insulated design.

Polyurethane foam is cheap enough costs during storage and transportation due to the use of compact source components.

Characteristics of polyurethane foam is ideal for upholstery, massively is used as an elastic filler in chairs and seats, sofas, pillows. Foam everywhere replaced cotton wool and cotton padding of household items, clothing and furnishings. This material is familiar to almost everyone. The foam is used for various household needs, according to his characteristics a little polymer can act as a substitute.

It finds application as filler in upholstery, and for insulation of clothing and footwear and as packaging that protects fragile and valuable items from shock during transportation. Total production of polyurethane products exceeded that of products from polyethylene and polatile?have tereftal?she (PET).

Some negative side ↑

Absolutely perfect materials do not exist. In addition to positive sides, rigid polyurethane foams produce separate characteristics for the worse:

- the instability of the action of ultraviolet light, it is necessary to apply protection plaster, or close panels or paint.

- a limited application in those places where it is possible excessive heating of surfaces or have a high likelihood of outbreaks.

- a very high price in the case of spraying.

Technical characteristics of the polymer will provide its production and use for many years to come.