Safe outdoor fire calming effect on a person. He creates an atmosphere of comfort and warmth. But not all have the opportunity to pitch at home or on the section of the fireplace. A great alternative to this device can be a fireplace – a living fire without smoke and ash. Unlike traditional options, the product does not involve the construction of a flue because the combustion process of biofuels is not allocated any harmful substances.

The contents

What is the product and how good it is?

Biofireplaces can safely be called a new generation of traditional wood-burning fireplaces and heating devices. Real living flame arising from the combustion of biofuels based on alcohols, it does not emit soot and smoke and does not leave behind traces of burning and soot.

Modern fireplaces have long won the love among a wide range of customers for their attractive appearance and security of the application

They can be installed on open sites of a suburban area, and indoors at home. But because an open fire tends to burn the oxygen, the room in which burns a makeshift hearth, you need to periodically ventilate.

Depending on the location of the device there are several types of fireplaces: wall, floor and table.

Wall – compact flat design, side and rear walls of which are made of metal, and the front part is protected by a glass

Table — are a miniature imitation fireplaces. They have protective glass screen, through which a clear view of the living fire

Floor – to- imitate traditional wood-burning device. They are placed on the floor in open areas or in recesses or the corners of the room

Depending on the size of the design fireplaces can have from one to several units of the fuel – burners. As the fuel most commonly used bioethanol, which leaves no products of combustion.

Bio fireplaces have many advantages: simple installation, does not require arrangement of the chimney, no dirt from the firewood, no soot and soot. The only drawback of popular heating devices is their price. However, master, master basic knowledge and skills of construction, will be able to confirm that to make a fireplace with his hands is not so difficult task.

We invite you to see the video, where is constructed a simple model of fireplace that you understand how simple it is:

Ways independent production of bio fireplace

Design #1 — miniature table device

For the manufacture of table and hearth, we need:

- Glass and glass cutter;

- Silicone sealant (for bonding glass);

- Metal mesh;

- Metal box under the base of the structure;

- The capacity of the fuel;

- Non-combustible composite materials;

- Lace wick;

- Fuel for biofireplaces;

For decorating the fireplace screen you can use ordinary window glass in a thickness of 3 mm or glass with photo frames.

The simplest form of desktop bio fireplace — with rectangular or square base. The arrangement of such designs will only take a few hours

As the metal mesh base is perfect baking pan for oven, barbecue grill or mesh construction made of stainless steel. For the arrangement of tanks of fuel you can use metal cups. Fuel block fireplace with the easiest way to make metal pots square or rectangular shape.

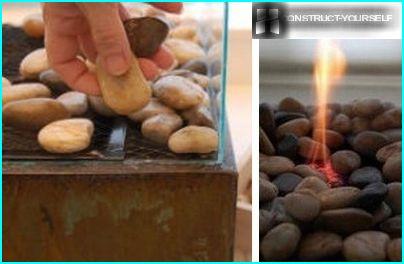

Alternative to non-combustible composite materials can be sea pebbles and any heat-resistant stones of small size

The structure dimensions depend only on the wishes of the master. However, when calculating, consider that the distance from the burner to the side Windows should not exceed 15 cm At the same time, when too near the glass to an open fire there is a possibility that it will break. The number of burners will be determined by the dimensions of the area or room. On average, an area of 16 square meters is enough tabletop fireplace with single burner.

Having defined the dimensions and given the size of the bottom of the fireplace with metal fuel block, cut 4 blanks from glass.

The pieces collected glass casing, which will act as a screen fireplace. Glass elements joined together with silicone sealant

Neatly connecting and proclaim all glass items, leave the screen to dry the sealant. The remains of the dried silicone sealant handy to clean off the usual blade.

To fix the glass blanks, the assembled screen inserted between fixed objects and leave it for a few hours

Proceed to the arrangement of the fuel unit.

In the center of the metal box set the jar filled with fuel. If for decorating the fireplace using two or more burners, they are placed in the box at a distance of 15 centimeters from each other

Do net deck options: metal grille with metal shears cut out a rectangle whose size corresponds to the dimensions of the box.

Metal bars placed on the walls of the boxes for reliability, grabbing the corners of the design in several places, welds

From lace twisted the wick and dip one of its ends in a container of fuel. Itself metal mesh covered heat-resistant stones, decorate with ceramic logs and other non-combustible materials.

Besides the decorative function of high-temperature rocks will evenly distribute the heat across the burner surface of the grille to the glass casing

Table bio-fireplace is ready. It remains only to set on a metal block glass box and set fire to a fuel-soaked wick.

Design #2 — angular variation for the gazebo

The angular variation of the bio fireplace is interesting in that it can be safely placed in a corner of the gazebo or veranda. Taking up minimal space, it will add to the atmosphere of hints of coziness and comfort, have a pleasant rest.

Since the product is subject to high fire danger, you should always leave enough distance from the hearth to the walls and superstructure

For making angular design we need:

- Guide and rack metal profile with a length of 9 m;

- 1 sheet of non-combustible drywall;

- 2 sq m of mineral (basalt) wool;

- Finish gypsum plaster;

- 2.5 square metres of terracotta or artificial stone;

- Grout and heat-resistant glue for a tile;

- Dowel-nails and screws;

- The fuel container;

- Heat resistant stones and incombustible decorative elements.

Having defined the location and design of the future home for the calculation of the necessary materials and visualization of the image on a sheet of paper, draw the sketch, observing the proportions. Then you can make, best to start with markup.

On the wall apply a layout, on which is attached a pre-cropped guide profiles. They plug-in rack profiles, fixing elements are screws

After checking the verticality of structure using plumb Bob, attach the frame to the wall using dowels, nails and screws. The fireplace stands for reliability, it is desirable to seal crosspieces.

The frame outside is sheathed with plasterboard, screwing it on the screws every 10-15 cm In the region of the furnace laid a 5-centimeter layer of mineral wool

In the bottom of the furnace leaving a recess in which are going to install the burner. Because in the process of operation of the hearth temperature around the burner can reach 150°C, the base fuel part make from hard non-combustible material.

The drywall construction zashpaklevyvaem and revetted with tiles, refractory tile or natural stone, which will be combined organically with the other elements of the recreation area

After completion of work fill the seams with special grout.

The fireplace is ready. Remains wipe the surface with first a damp, then dry cloth and put a heat-resistant stones and decorative elements

As the capacity for biotoplivo convenient to use a special tank or a cylindrical burner. To ensure the safety of loved ones, the front wall of the fireplace can be closed heat-resistant glass and wrought-iron fireplace grate.

Do the fuel for that hearth

Fuel for biofireplaces is the bioethanol – liquid without color and smell, contains alcohol and act as a substitute for gasoline. Its main advantage is that in the process of combustion it does not emit harmful gases and does not leave soot and grime. Therefore, the biofuel fireplaces do not require the installation of hoods, resulting in absolute heat. And besides, in the combustion process of ethanol by the liberated water vapor is humidification.

Purchase fuel in specialized stores. It comes in plastic bottles and cans. One liter of fluid is enough for 2-5 hours continuous burning

Fuel for biofireplaces can be done with your own hands. This will require:

- Medical alcohol 90-96 degrees;

- Lighter fluid Zippo.

Gasoline can turn the blue lab fire in the living centre of orange. You only need to mix these two components in such a proportion that the gasoline amounted to 6-10% of the volume of rubbing alcohol. Ready composition thoroughly agitated and poured into the fuel container. Fuel consumption is 100 ml per 1 hour of burning.

After fuel ignition the first 2-3 minutes until the flame is small in radius of several meters from the fireplace there is a slight smell of alcohol. But as the heating fuel when couples start to burn, not the liquid, the smell quickly dissipated and the fire becomes alive and playful.