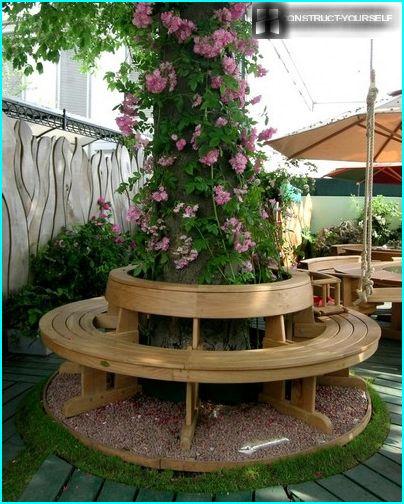

The beautification of landscaped grounds – business not one day. In addition to the construction of the main buildings and the arrangement of the garden you always want to allocate a place for leisure, where you can enjoy unity with nature. And the main element of this cozy corner under the open sky will act as garden furniture. If free space on the plot not so much, you can use tree trunks region trees, installing under them a round bench with a table. How to build a circular bench and table for garden around for wood, consider in more detail.

The contents

Where better to build such furniture?

Bench around the tree for many years at the top of popularity among landscape designers and connoisseurs of comfort and beauty. Of metal or wood, with backrest or without, simple designs or elegant ornamented products – they never go out of fashion.

The reason for this popularity is likely that they are framing guns. Large sprawling trees are attractive and are per person, because under his powerful branches any feel secure.

The bench under the tree – a symbol of unity with the surrounding nature retaining their functional and decorative qualities, it becomes part of the inhabited garden

A key element of this pair, of course, wood. Therefore, framing his bench should not hamper, and even more damage to the barrel. Round bench best set under a chestnut tree, birch, willow or walnut.

Fruit trees – not the best option. Deciduous fruit trees will spoil the appearance of the furniture, leaving marks on a light wood surface.

Well, if from the bench will open a picturesque view on a beautiful flower garden, pond or arch with climbing plants

Hot summer days on a bench to relax, hiding under the shade of the foliage. In the autumn months when the leaves will fall, you will enjoy the warmth of the last rays of the sun.

The choice of materials for construction

Garden furniture is designed not only to provide comfortable conditions for rest in the center of the green spaces in the fresh air, but also act as a bright accent the original design of the shaded area.

Material for its production can be: wood, stone, metal. But still most harmoniously in the garden looks that wooden furniture.

Possessing unique textures, benches of wood look equally good as among the greenery and in the backdrop of stone and brick buildings of the area

Choosing the material for creating wooden benches or tables, choose wood with a dense structure. They are better able to withstand the negative impacts of rainfall, maintaining a presentable appearance for multiple seasons.

Great for making garden furniture larch: number of oil and adhesives makes it the least vulnerable to high humidity and temperature fluctuations

Among cheap rocks for the manufacture of outdoor tables and chairs good for pine, acacia, cherry or spruce. Beautiful color and texture have oak and walnut. But even with the high-quality treatment they are less resistant to climate change, and under the direct sunlight can do gradually crack.

Regardless of the choice of wood species, to garden furniture lasts for one season, all wooden parts and elements must be treated with a protective impregnation for both front and back side.

Master class #1 — master circular bench

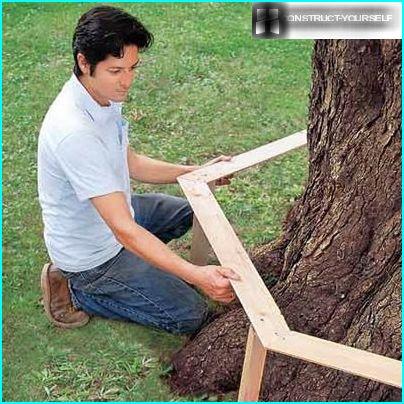

The easiest option is making a circular benches – the creation of a hexagonal structure, a backrest attached to the trunk of the tree. The legs of the bench must not damage the aboveground parts of plant roots. Determining the distance between the seat benches and the tree trunk needs to have a stock of 10-15 cm on its growth in thickness.

For making round bench, which will act as the frame of a tree with a trunk diameter of 60 cm you will need:

- 6 blanks 40/60/80/100 mm, width 80-100 mm;

- 12 pieces with a length of 50-60 cm for the legs;

- 6 pieces with a length of 60-80 cm for the cross members;

- 6 slats for the manufacture of the backrest;

- 6 strips to create the apron;

- screws or screws.

Use only well dried wood. This will reduce the possibility of cracking on the surface in the process of operation of the bench.

Of the tools you need to prepare:

- a screwdriver or screwdriver;

- a power saw or hacksaw;

- bolgara with an attachment for grinding;

- garden shovel;

- hammer.

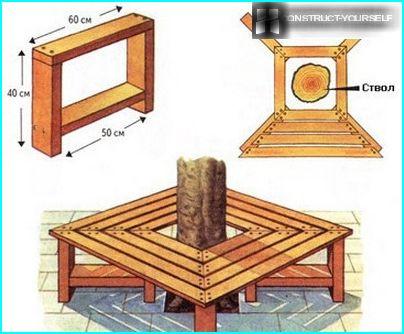

The circular bench is a structure consisting of six identical sections. The size of the sections depends on the diameter of the tree. It is measured at a height position the seat, adding to the result of 15-20 cm in stock to ensure further growth of the tree. To determine the length of the short sides of the inner plates of the bench, the result of measurement divided by 1.75.

To the circular bench in the assembled had the correct shape and perfectly smooth edges, the cut angle of each section must be equal to 30°

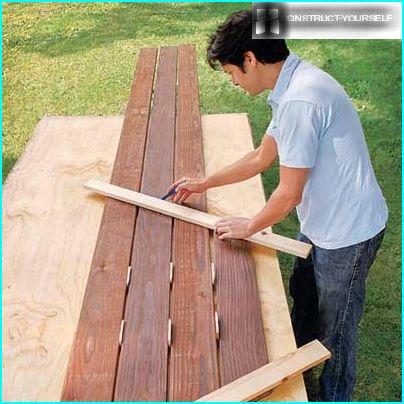

To create a symmetrical flat faces and get straight bevels between adjacent slats of the seat when cutting the parts should be connected between the foot boards.

Blanks for the seat are laid out in four rows on a flat plane. To the assembled Board seat belonged rug close to each other at the Assembly stage of design between them set the gasket thickness to 1 cm.

On the Board, which will act as a short side of the internal plate of the bench, plan places cut at an angle of 30°

Outlining the cut at the Board transfer line and on the boards of adjacent rows, maintaining the same angle of inclination. In each following row of plate longer than the previous. The same technology cut 5 more patterns of the same size.

The correct dimensions of the seat are easy to check, laying out all the templates and docked their edges so as to obtain an equilateral hexagon

Convinced of the correctness of calculations and correct Assembly of elements of the seat, start making the legs of the bench. Design circular benches includes installation of inner and outer legs. Their length depends on the desired seat height. On average, it is 60-70 cm.

To give rigidity connect the legs with cross members, the length of which is equal to the width of a bench seat

Cut out 12 identical legs on the seat height. If the ground around the tree has an uneven surface, the blanks for the legs take a little longer than the planned size. Later in the installation process, you can always trim the height of the pour or, conversely, removing the layer of soil beneath the legs of the bench.

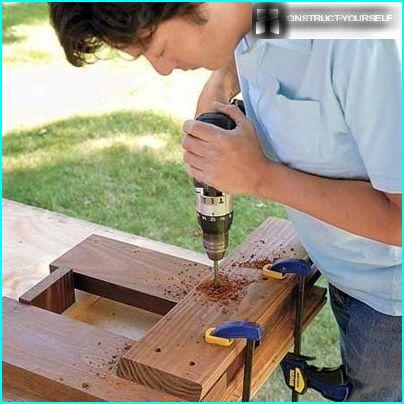

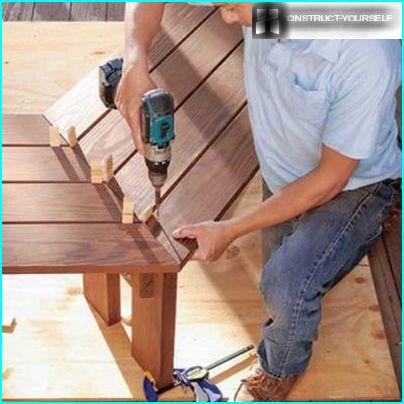

To connect the legs with cross members parallel to each other, on the supporting pillars and the crossbars are doing marker tags, which will act as a guide when drilling through holes. To create a rigid structure holes drilled in a staggered manner, placing them diagonally and grabbing your legs with crossbars.

Through the holes insert bolts and strung them on a washer to a nut using a wrench firmly tighten. The same actions performed when tightening of the other five nodes.

To connect the legs with the seat of the bench is easiest by installing them in an upright position and fixing it with clips and then put them on the Board seats

Strip seat post on support legs so that the joints between the boards was located strictly in the center over the feet. Themselves strip you need to move in the direction of the front feet so that they go beyond the edges.

Make sure the correct Assembly connecting two adjacent sections. First fasten the outer column support, and then «put» screws on the inner legs. The result should be collected two plots of land, each of which includes three interconnected bands.

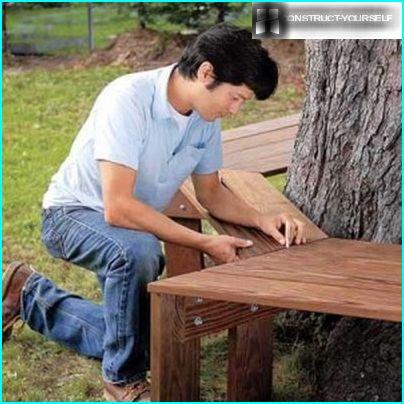

Collected half circular benches set on opposite sides of the tree, joining the edges of adjacent strips

«Nazivu» the joints, re-adjust the location of the external three pillars, and then tighten the screws. Aligning the horizontal surface of the bench level, proceed to the installation of the backrest.

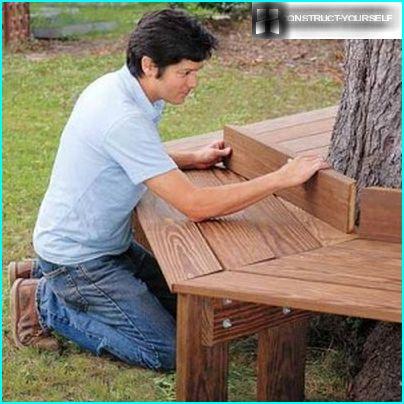

Backless all six seats set at the back edge, placing them flush and fixing by bolting

For easy operation the bevel end cut off at an angle of 30°. To commit the elements of the bench guides the tightening screws through the holes on the inner side of the seat and grabbing the backrest. The same technology connect all contiguous back.

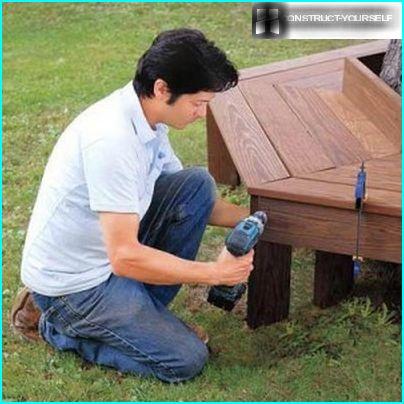

In the final stages of separate strips mounted apron. To determine the length of the strips is to measure the distance between the outer legs of the bench. Cut into six pieces for the apron, the short edges of each of the bevel angle 30°.

To install the apron, alternately attach the Board to the outer sides of the seat, and, fixing clamp, fasten the screws to the legs of the bench

Ready bench remains only to Polish, removing all roughness, and to cover the insulating oil impregnation. Give a good result also compositions based on wax that creates a thin surface film that prevents the penetration of moisture from the environment.

The process of making tetrahedral bench is a little different from the technology of production benches hexagon shape

Installing a circular bench in a cool corner of the garden, you can at any time enjoy, leaning on the rough bark of the trunk and listening to the sounds of nature.

Master class #2 — build around the wood garden table

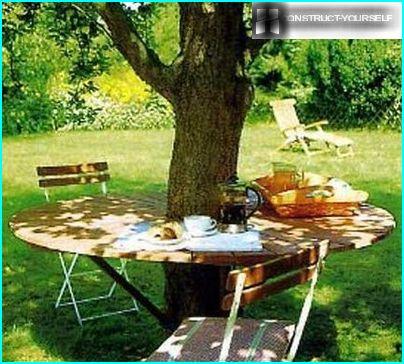

A logical addition to the circular bench of the garden will be the table around the tree, which can also be installed under the adjacent plant.

Under the arrangement of the table is better to choose a tree with a spreading crown, to the shadow of it covered not only the countertop, but seated at a table of people

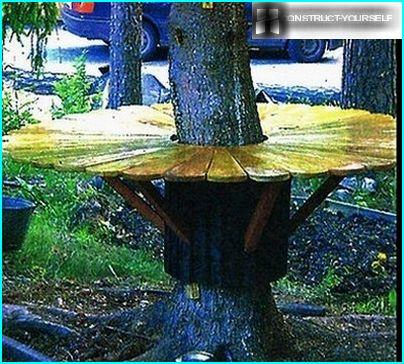

The type and shape of the table can be any ranging from traditional square designs and finishing tops irregular shape. We propose to construct a structure the top of which is made in the shape of the head revealed flower.

The project is for the design of the trunk of a tree whose diameter does not exceed 50 cm If selected for the installation of the table you tree is still growing, be sure to make additional headroom under the center hole of the countertop.

To make table around the tree you will need:

- a piece of plywood with a thickness of 10-15 mm, a size of 1,5×1,5 m;

- Board thickness 25 mm and size 20х1000 mm;

- 2 piece metal strip with a width of 45 mm and a thickness of 55 mm;

- wooden block 40×40 mm;

- screws for wood and metal;

- 2 bolt tie strap 50h10 mm;

- 2 nuts and 4 washers.

- paint and metal impregnation for wood.

When determining the size of metal strip guided by the thickness of the wood, but make an extra supply of 90 mm for fixing parts.

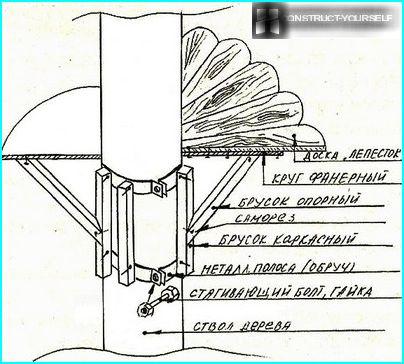

Boards for the table top is treated in the form of a petal, rounding out the outer edges and making the inner part to the middle of the flower is narrower

From a sheet of plywood, cut out the circle with a diameter of less than 10-12 cm than the size of the tabletop. In the center of the circle cut out a hole the size corresponding to the thickness of the trunk. For the installation of a circle cut in half, billet varnish.

The construction frame constructed of bars with a length of 40 cm and 60 cm billets size 60 cm cut the ends at an angle of 45° so that one side will retain the same length. Wood cleaned with sandpaper and coated with impregnation.

The ends of two lengths of metal strip 45 mm section bent at right angle and coated with 2-3 coats of paint. To assemble the design, the metal billet tie rods so that their ends do not protrude beyond the edge of the strips. The result is a design that looks like a barrel, but in mirror performance.

Assembled frame is worn on the trunk of the tree, placing the metal elements are strip – cuts of linoleum. Bolts and nuts are firmly tightened. To the vertical frame members by means of screws fasten the semi-circles out of plywood. On plywood circle, you spread the petals, forming the top of a flower.

Each petal «flower» fix the screw, the maximum buried hats so that they do not protrude above the surface

The surface of the petals are treated with sandpaper. If desired, the cracks between the boards coated with epoxy. The side faces and the surface of countertops are treated with a protective composition, which will minimize exposure to moisture and insects. To give the table the desired color, use the impregnation with the ordinary pigment or stain.

Whichever option circular bench or table you choose, the main thing – that it was in harmony with the surrounding landscape. In any case, outdoor furniture made with your own hands, every time to delight you with its originality and uniqueness.