The contents

The surest way to do work with their hands efficiently and «for centuries», if you work with the material in treatment which is specific knowledge and skills. It is easier and safer to construct and install a canopy over the porch, using welded steel profiles and sheets of corrugated sheets. In the garage of anyone who loves to work, build or just tinkering, always find a grinder and welder.

Choose the design of the visor ↑

Most of the most fanciful and graceful in form wrought iron canopies over the porch, in fact, functionally identical to the welded steel frame structures made of metal profiles. They are certainly more graceful and beautiful, but in terms of functionality special advantages do not have.

Most acceptable to build, practical and affordable to manufacture their own hands is the design of the visor with a flat surface and a small angle of the slope:

- Welded metal construction will withstand even the weight of a person, so safe enough for any rain and gusts of wind;

- Light weight metal visor will not require massive welded support beams, the whole system is a console on the facade of the building;

- In comparison with other options, the cost of welded metal constructions of the building of the visor just a hair, it will not exceed a few tens of dollars, while the bulk of the costs go for the purchase with his own hands a metal profile or metal, set the overflow gutters.

All that relates to the size of the corrugated sheet and design of the drainage system, everyone is free to choose their own for their own reasons, they on the safety of the visor is not particularly affected.

Size, tool and metal profile for visor ↑

First of all, we need a tubular metal profile with a cross section of 20-25 and a length of 11-12m. Next, three meters steel strip 3х20мм, two or three sheets of metal roofing 120х90см, metal corner 50 and a dozen bolts, dowels used for fastening metal to concrete or brick wall, wooden plank or Board with a thickness of 20mm, screws for fixing metal profile.

From the tool will need a corner machine cutting circle on metal, electric welding apparatus, a device for profiling metal strips. Welds to comply using poseshenie electrodes on the black iron, with a diameter of 4mm. Almost all of these materials available at any hardware store

Make the design of the visor ↑

Design metal canopy, as is well seen in the photo, is a G-shaped frame structure. The basis of the deck consists of two longitudinal and four transverse welded rack. To the frame of the deck at a right angle are welded two side metal welded stand design, ensuring the rigidity and strength of the anchoring of canopy on the facade of the building.

Welding works canopy ↑

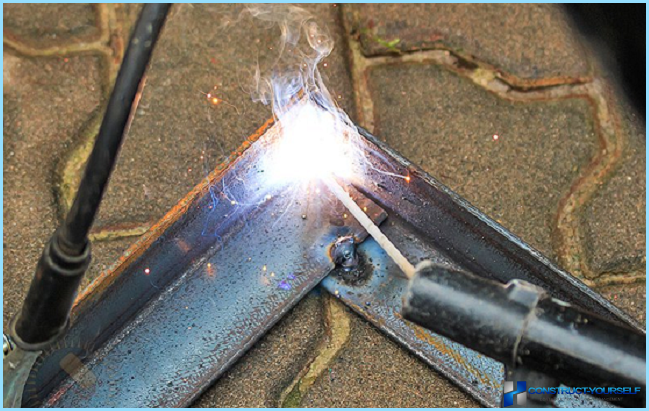

Cut with a grinder the pieces of metal profile rails with a length of 200cm and in the transverse ribs with a length of 120cm. In addition, their hands cut out the two metal side plates with a length of 100cm. All the elements to mark up and cut off grinder with an allowance of half an inch, as in the photo.

Collect your hand set in the following sequence:

- Spread on a flat surface, better on the concrete floor, longitudinal and side elements of the frame of the shed, divide them in pairs into two sets – one longitudinal, one lateral and one intermediate bracket in each set;

- Using a square and clamps place and fix the right angle between the lateral and the longitudinal strap, running welded ¾ the weld joint exhibited similar second – intermediate and is also welded, as in the photo;

- Similarly weld the second set of elements of the metal framework of the canopy;

- Will succeed; and align in the plane of two of the welded terminal in one frame, all welds check and clean from slag.

After completion of Assembly work of the frame of the canopy perpendicular to the plane, as pictured, welded metal side struts of the canopy, by which the entire structure will be mounted over the porch.

Set lateral console stand ↑

The design of the visor, are designed for simple outbuildings, you can stop at this result and go to the process of fixing a flexible roofing. But the front porch would be a nice add with his own hands small decorative items and be sure to set the side arcs, or struts.

For each of the lateral uprights will require one half meter interval profile. Both workpiece bend arc at the bending, as in the photo, or using manual cutter radius R=3.5 m. If it is not possible to do with their hands, it is easier to order the arcs in the metal workshop. The arc can be mounted directly on the frame to enhance the decorative effect is better to use an intermediate support profile, length 8-10 cm, as in the photo.

In the space formed between the arc and the sides of the frame, you can insert a few curls from strips of strips of metal or scraps of wire rod. The picture gets their hands individually on a flat surface and after the Assembly is attached to the arc and the sides of the frame, as pictured.

With a certain skill and imagination they complement and decorate the external appearance of the visor. After the Assembly design should be primed and painted «hammer mill» enamel shades old bronze.

The installation of the roof ↑

At the final stage, the plane of the canopy mend Board section 20х150мм every 15-20cm. This is sufficient for the installation of corrugated sheets or of sheets of metal. If you prefer to use a soft roof, the plane of the visor, you will need to score a butt clapboard or sheets of OSB.

The lower part of the visor if you want you can sew the PVC profile used for walls in the bathroom.

Installation of canopy on the facade of the building ↑

The weight of the visor was not small, not less than 12kg, which involves the use for attaching at least 6-8 points of anchor bolt connections. This visor is better to fix on the prepared basis from strips of metal.

Collect intermediate fastening of metal ↑

According to the measured dimensions metal visor to mark up the line fixing on the facade above the porch of the building and layout, through drills and dowels fasten strips of metal in the shape of the letter P.

On each side of metal strip needed to make 3-4 points of attachment, a vertical longitudinal strip of metal should be at least 3 fixing points to the wall.

Then his assistants put a metal visor with a block on the site of the future mount designs and record improvised material. Using a Builder’s level, adjustable to the horizontal position of the visor so that its metal side stand fits snug against the previously attached strips of metal.

The most reliable way to control the position of the visor over the porch – move to a dozen meters and from a distance to ensure no distortions or tilting of the structure. In the absence of comments weld welded corner points of the side posts of the canopy to the prepared metal base on the facade.

Installation of drainage gutters ↑

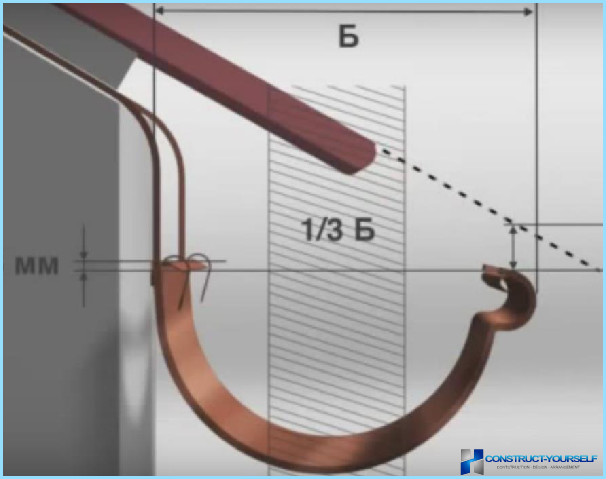

The diversion of flows of water from the surface metal of the visor is done using standard gutters made of plastic or metal with a set of fasteners. It is important not only to set the chute, but it correctly to adjust.

The overflow pipe is attached directly on a metal longitudinal beam of the canopy, do not install, as it often spoils the appearance of the structure. More reasonable is the use of the second metal chute that will lead the main part of the flow of water to a more convenient location of the catchment and does not affect the shape of the visor over the porch. In any case, you will need one 2-meter main chute and 1.2 meter side auxiliary adapter to the drain pipe.

Conclusion ↑

Metal visor above the porch from metal was somewhat heavy, but the frame made of metal is a guarantee of a long product life, high durability and resistance to rain and big snow. With proper execution of the work metal frame that will withstand the weight of a person.

A similar construction can be made of aluminum, but reciprocal links will have to use additional parts or adapters from more durable metal. Very metal design happens twice easier and prettier.