The contents

Its significance is the furnace for a bath, you can compare with the human heart: from the parameters of its operation depends on the temperature in the sauna room and steam quality. Despite the abundance of modifications, functioning on electricity, liquid fuel or gas, the tradition is to heat up the sauna wood-burning stove does not disappear. The cosy atmosphere in the steam room depends not only on temperature and level of humidity, the sound of crackling firewood and the scent creates the ideal conditions for relaxation.

Classification of wood-fired furnaces ↑

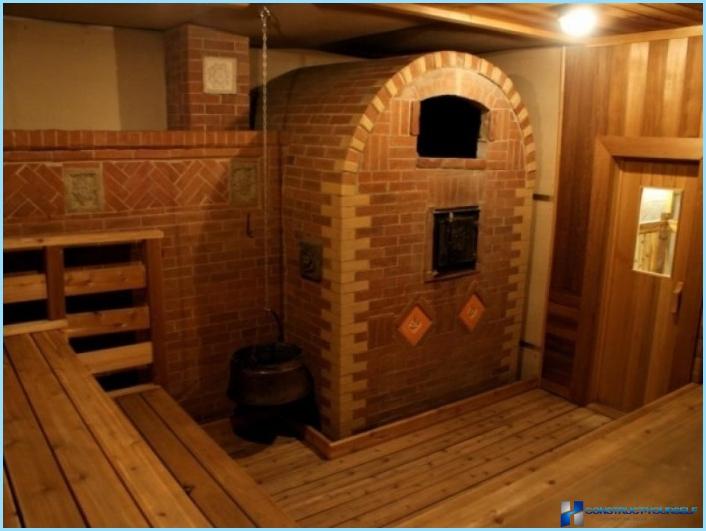

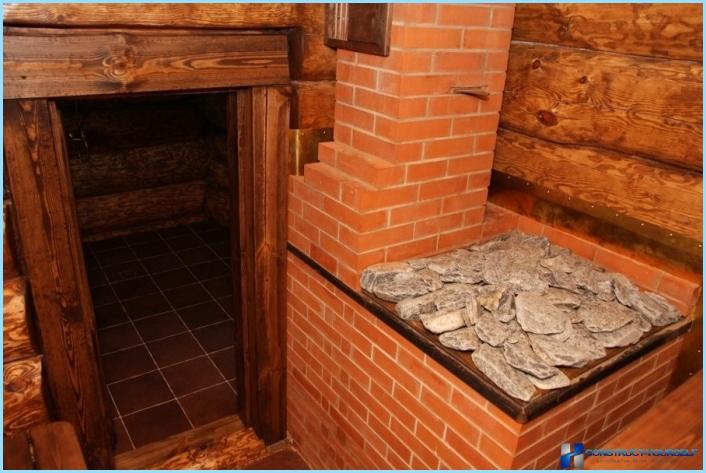

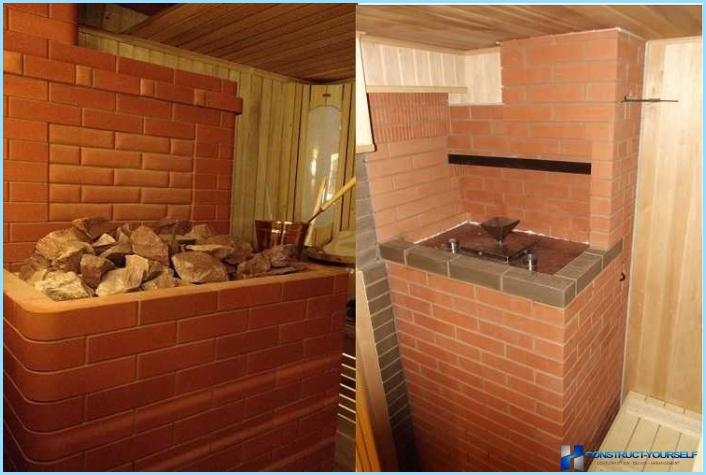

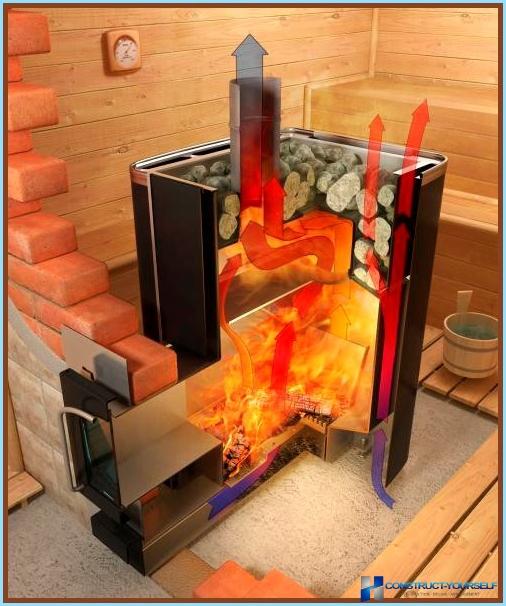

Thinking about installing in the bath, a wood stove, you should carefully examine the features of various models. If before the stove for a bath was made exclusively of bricks, modern trade and craftsmen offer a wide variety of metal structures. In addition to the material from which made the housing a wood burning stove different is equipped with a heater. Depending on the desired level of further operation, with the heater of the open type and closed. Modern equipment brick wood-fired oven involves only the presence of a closed heater. Metal model for the bath is available in three versions:

- stone backfill is closed;

- the stones are on the outside;

- combined models, where closed stove coupled with an open tank.

Structural features divide wood stove to devices constant and periodic action. Another point that deserves attention is the location of the furnace:

- it can be directly in the steam room, which is accompanied by serious difficulties;

- most common option remote fuel door located in the anteroom;

- in rare cases, the piece of wood is from the streets.

The wood-burning oven, both metal and brick, have undoubted advantages, but their operation has a number of features. After reviewing the characteristics of both types to decide which model is better for a bath will be easier.

Feature brick structures ↑

A classic arrangement of a Russian Banya involves the presence of brick furnaces, with the following properties:

- the ability to maintain the high temperature of the stones for a long time;

- emit a pleasant, soft warmth;

- to create the best options to stay in the steam room;

- ease of operation and long service life.

Wood burning stove successfully absorb hard radiation. After a full warm-up of the bricks, it gives the accumulated heat of the heat radiation and not by convection as in the metal models. Due to this, the resulting heat creates a pleasant feeling. Having made the decision to equip the bath wood-burning oven of brick, be prepared for the following problematic points:

- The cost of material and services of a professional Builder would cost for a budget in a significant amount.

- The additional costs of time and money will be required when construction of the Foundation and chimney for a wood stove.

- Compared to metal structures, the installation period is greatly increased.

- Thermal inertia prevents rapid changes of the temperature regime.

- The minimum time for the preparation of the room – 5-6 hours.

- Heating of the big mass of bricks requires large amounts of firewood.

- Wood burning stove, made of brick, is in the bath a vast area, unless it is a structure made using the developments Kuznetsova I..

In finding easier ways of equipment furnaces for a bath on firewood, consumers are increasingly using the option of metal structures, sacrificing the traditional method of producing a comfortable atmosphere.

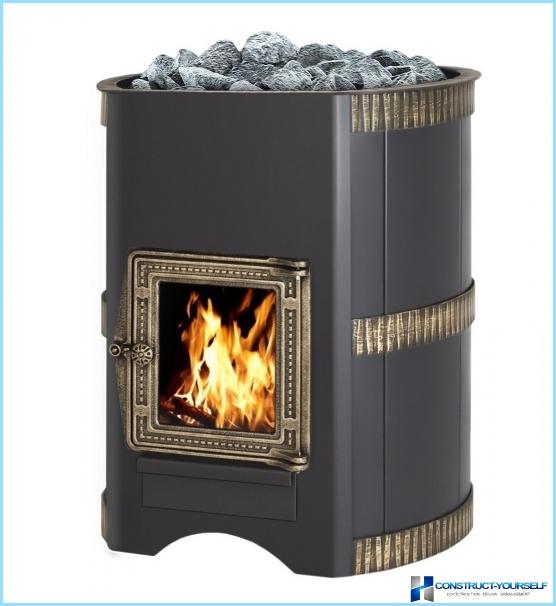

Features metal models ↑

Tooling a Russian steam bath with a wood burning stove, metal model in its pure form is not able to create the required parameters, as the optimum temperature of the steam room should fluctuate in the range of 60-70onC. to Achieve the specified parameters allows the arrangement of the metal casing of the screen. The essence of the method consists in the construction around the kiln brick walls. The gap between the metal structure and brickwork is 5-10 cm, screen height – not below the level of the wood-burning oven, an optimum wall thickness – 120 mm, although it is possible to increase or decrease the proposed size.

The advantages of a wood-burning metal stove weight:

- Relatively low cost.

- Needs no additional infrastructure Foundation. When mass less than 200 kg it is sufficient to equip non-combustible floor base. Exceeding the specified limit will require to strengthen the joists and pick up planks.

- There is no need for equipment brick chimney. The most popular option in recent years is the use of sandwich pipes. The output of the design is allowed through the wall or ceiling.

- Warming up the steam room takes a short time, the maximum period does not exceed one and a half hours.

- The compact size will help the owner of the baths with limited space.

- To install the not compulsory support and assistance of professionals, a wood burning stove made of metal is quite possible to install it yourself.

After reviewing the advantages of the design, it is useful to know about the problematic aspects of the issue:

- The high temperature of the walls present even in furnaces with an open heater where the walls are separated by rocks. Unintentional touch will inevitably cause a burn. Additional protective fencing will reduce the risk of injury in the bath.

- Low thermal inertia contributes to the rapid cooling. After having a steam to dry bath oven is recommended to heat again. Wood consumption will increase, but the room will stay longer: dry wood prevents the development of bacteria and fungi.

- Hard mode operation and non-uniform heat load contribute to the rapid deterioration of the housing a wood-burning oven. Therefore, the thickness of the metal and the construction of the furnace deserves when you select attention.

The popularity of metal models due to their low cost and ease of installation determines the need to examine in detail aspects of a choice of different wood burning stoves for baths.

The nuances of furnaces ↑

Creating the project of a bath with a wood oven fuel loading is preferable to set up outside the steam room. Apart from the question of the allocation in the steam room additional space for firewood and the creation of further debris, there is a more serious problem. Burning wood is accompanied by a rapid combustion of oxygen, which is unacceptable in a compact volume of space. Equipment the steam room in the bath high-quality ventilation would increase fuel consumption, and this is undesirable. More competently to organize the furnace wood burning stove in the adjacent room, to prevent loss of oxygen.

One of the deciding factors when choosing a wood construction is its capacity. To calculate the required indicators, in addition to the volume of the room, take into account the degree of insulation of the bath. Choose a power wood-fired oven is better with a small margin that it wouldn’t work to the limit.

Metal construction for work on wood is made from cast iron or stainless steel in black. The budget copies for the bath is made of ordinary steel, slightly higher model of the structural steel. Options cast iron wood burning stoves for baths are more expensive, this is due to their increased durability in compliance with the requirements of the missing water on a hot surface. To meet these conditions in the steam room is very problematic, and the spray can cause cracking of the cast iron housings.

Stainless steel wood stove will last a long time, if the welding of the hull was carried out in a specially equipped chamber with inert environment. This prevents evaporation at the seams of alloying materials for stainless properties of metal. The thickness of the body of the furnace for baths also plays a significant role. The bigger it is, the longer the lifetime of the model. To save material consumption and reduce weight design allows the manufacture of stove wood for baths with the use of sheets of different thickness. On plots of the maximum load install thick sheets, where the temperature is gentle, the material is selected thinner.

Among domestic manufacturers worth mentioning high-quality wood-burning stoves for baths Teplodar company, offering 7 versions. Rapid heating of the bath will provide the cast-iron stove «Siberia». If you need to conserve come to the aid of a wood-burning stove «Russia» and «Sugar». Model long burning «Termofor» reduces fuel costs, are noteworthy designs for the bath «Ermak».

High-quality and expensive material used in the production of the Finnish wood-burning furnaces for baths. Their distinctive feature is the environmental safety. This is based on reducing the level of emissions of carbon monoxide by 80%. The most popular brands of heaters and Kastor.

Selection of wood stove depends on the frequency of visiting the baths, its size and priority of desires – is it important to provide soft comfortable heat or it is necessary to quickly warm the room.