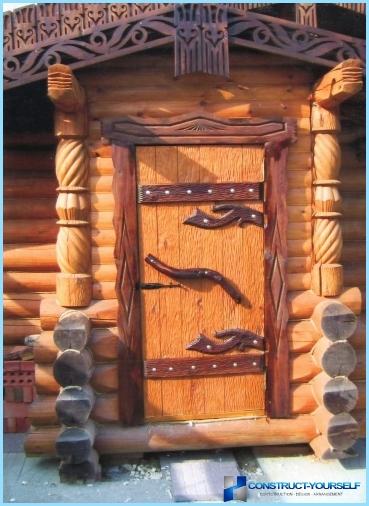

Bath or sauna at their summer cottage – the building is necessary, it is possible to tell, obligatory. You can argue about better or worse, in the bath or sauna, to relax after work and what better helps us to regain strength and health. The construction of these «Wellness» facilities requires a professional approach and adherence to all requirements. Details in this case, every detail matters. And think about how the door is installed, costs in advance. In this case, it is difficult not to agree with the definition that was given by the famous Mitrofan in «Greenhorn»: «Of the door? This? Adjective. Because attached to its place». Truer words were never spoken. Here we will look at different types of doors to choose quality and liking. After correctly made or chosen in the shop door in the bath saves up to 30% heat. And without the heat bath is not a bath at all, so, wash.

Doors for baths and saunas wooden ↑

The main door in the bath that leads into the steam compartment. The requirements it imposed special due to the fact that the temperature difference between steam room and dressing room reaches several tens of degrees:

- The cloth should not be hot.

- The canvas should not deform under high temperatures, and, especially, to break down.

- The cloth should be resistant to high humidity in the steam compartment and to the water condensate.

- For the manufacture of the door to the steam room uses only the so-called «bath rocks» trees (as well as for interior design steam room): aspen, basswood, ash, oak, alder, abachi. The preference for aspen and Linden trees – they are easily treated, they tolerate high temperature and humidity in the steam room, and are considered medicinal trees. You can’t use conifers, exposed to high temperatures they will secrete resin, which, among other things, and you can get burned.

- Door handles in the steam compartment is also made of wood. This is a safety issue.

- All doors in the bath opens to the outside. This is a common and mandatory requirement – in the event of any incident must be able to quickly leave the room.

- In the design of the door in the steam room, the office shall not apply locks.

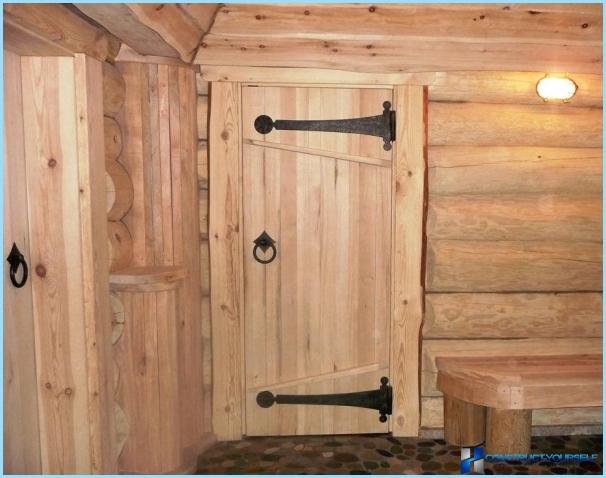

- The door hinges are fastened from the outside. This is done in order to avoid burns on hot metal and extend loops in more «calm» conditions. The considerable weight of the structure dictates the need to use three loops. Preference is given to brass loops.

For the best conservation of heat in the steam compartment, the door to it is a smaller size than a conventional input. Experts advise not to use a door height of more than 1700 mm and a width over 700 mm. on the external side should be the threshold height of 150-200 mm.

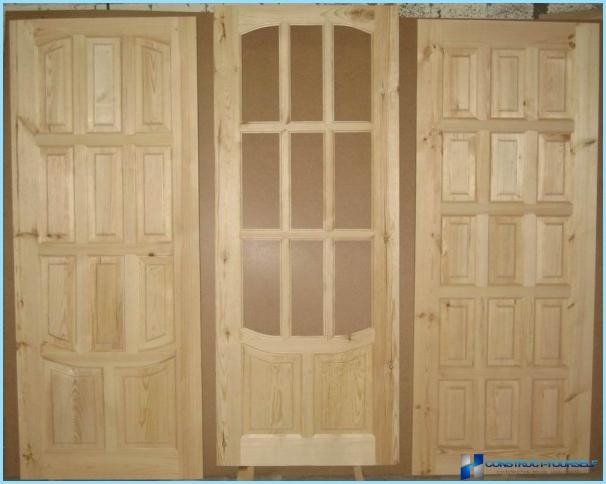

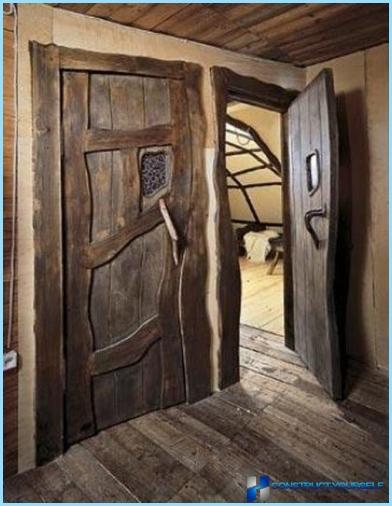

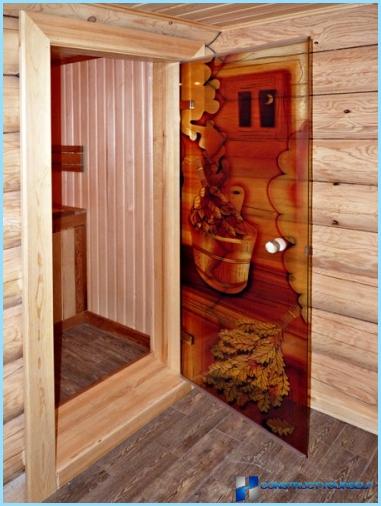

Solid wooden door is the best choice for baths, and even proven for centuries. The only retreat may be a small viewing window cut into the canvas. The Windows must be sealed and the glass used is tempered. Craftsmen decorate solid wood door with carving on the canvas.

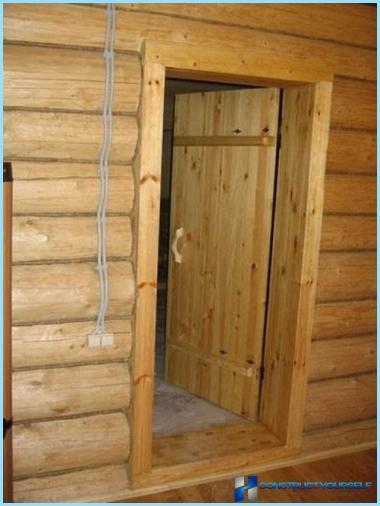

Door for bath with his hands ↑

Select the appropriate type of wood (some of these trees are quite expensive) and purchase the floorboards. Board thickness 30 mm, width 50 mm would be optimal. Can «cheat» and by planks of cheap wood, and sheathed with panels from valuable breeds. The same technique was used by Porthos – one of the heroes of the immortal novel «The three Musketeers», whose coat looked very expensive.

You will have in the process to use a milling machine and a circular saw. If you deviate from the intended target you do not intend to, advise to spoil a couple of boards, practice on them. It’s not too high a price for the acquisition of useful skills.

In addition to grooved boards, you’ll need lining 12х96 mm, beam 60 × 80 mm, 100×100 mm timber, furniture pins and screws. Essential tool milling machine and a circular saw we have already mentioned. In addition they will need a screwdriver, hammer, mallet, clamp and bubble level.

Prepare the canvas ↑

Boards cut to the desired length, one Board cut the spike. Do the preliminary Assembly of the canvas. The spikes should snugly fit in the grooves. The width of the blade will get a little more than required, it’s not scary. Cut at the extreme segments of the leaf equal parts, without touching the spikes and grooves, thus to reach the desired size. Make sure the surface was smooth. If you want to align, go canvas the jointer.

When you get the right size, assemble the cloth on the table. Miss pre-grooves with white glue, then insert the Board with spikes, helping yourself with a mallet. To dry the glue will be about three days. During this time, the canvas should not «the story». To avoid this, it is tightly fixed with two straps, closed by a sheet of chipboard and clamped with clamps. If one of the straps not enough crack between them and canvas wedges for a more secure fit. After the glue has dried, the canvas if necessary, you can handle a plane.

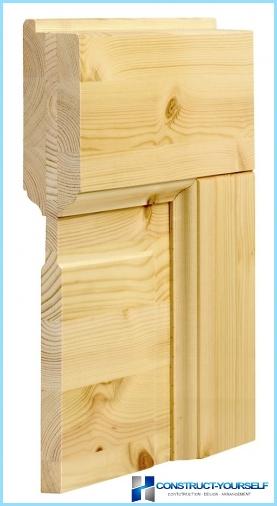

Binding ↑

Use three days, until the canvas was dry, for the manufacture of strapping. To do this, the boards are cut to the desired size. The vertical part needs to match the door height, and the horizontal to be a little less. It is necessary to consider the part that will have on the vertical part of the door.

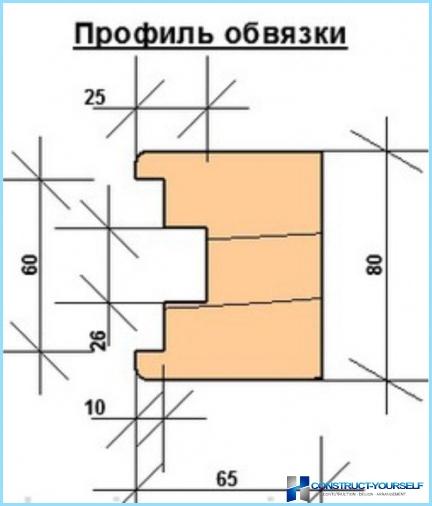

Then apply in practice the acquired skills on the milling machine. In the center of the beams for the vertical part of the piping of the end mill selected groove (depth 25 mm, width 26 mm). It will stand up tongue-and-groove boards. Repeat the operation and select a wider groove on the first (depth 10 mm, width 50 mm). The second notch is for lining.

On the bars for the horizontal part of the step, select the tenon in the groove in the vertical part of the trim. Check and achieve a perfectly precise fit of all elements. If necessary, podnachivaet cutter.

Trim, canvas lining ↑

Cloth and piping the treated stain. Experts say that aspen can not handle, because its wood is susceptible to fungi and parasites. Interestingly, this property of aspen in some way associated with an ancient legend about this tree and about the reason why people use the expression «shaking like a leaf»?

Stepping back to 15 mm on each side from the edge of the fabric, mark the border for covering paneling. Battens cut to size and nailed to the canvas with nails or fasten with screws.

The harness installs in that order – first vertical part, a horizontal after them. All the elements are driven with mallets. In the selected vertical elements of the framing grooves and the base of the top horizontal beam, apply PVA. The bottom horizontal bar is not stuck – when the time comes to repair, it will be easy to remove. For reliability and screw three screws in each vertical element of the binding and two horizontal. The door is ready, it remains set wooden handles.

Finish ↑

First pass with fine emery paper and sand the paneling. Especially try not if the lining is good. Concentrate on the edges and remove the chamfer. If you are confident in your abilities, use shaped cutters to make the pattern on the door. This door will immediately draw attention to themselves. As another option for the decoration, use a decorative strap and Reiki. In the shops and construction markets has a huge selection.

Installation ↑

The door frame is made of timber 100×100 mm Timber cut to size and cutter choose quarter. For connection of bars top and bottom cut grooves, spikes are made on the edges of the top and bottom of.

In aperture, select the grooves for installation of the box. The width of the groove do 8-10 mm larger than the box size. So we will be able to correct its vertical position. Do not forget that the door to the bath should open outwards. Insert the box into the slots. First, set the upper horizontal part, propping it with vertical bars. Then install the bottom rail. Check items level box needs to stand upright. Fix the box by means of wedges that score between it and the wall.

Set loop. Fasten the top, stepping down from the top edge of the door is approximately 250 mm, the second bend from the top 400-500 mm, and the lower one retreating about 200 mm from the bottom edge. The asymmetric location of the loops will allow you to avoid twisting of the heavy wooden door. Hang it on hinges and sealed the gap between the frame and the wall.

Difficult? Yes. But no one promised it would be easy. It is only in the TV programs about repairing the door hung for a minute or two. But it is unusual – heavy, wooden, for saunas, and lining padded. But your hands made.

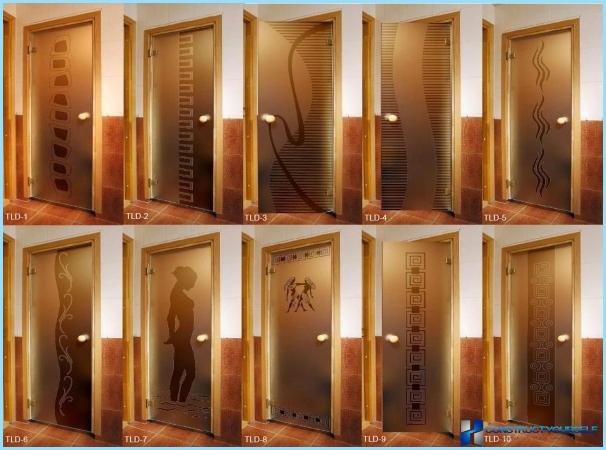

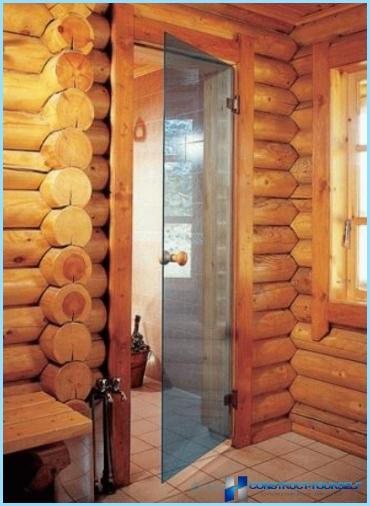

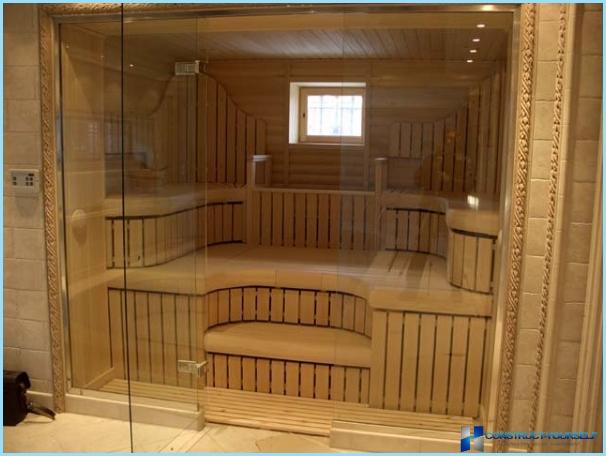

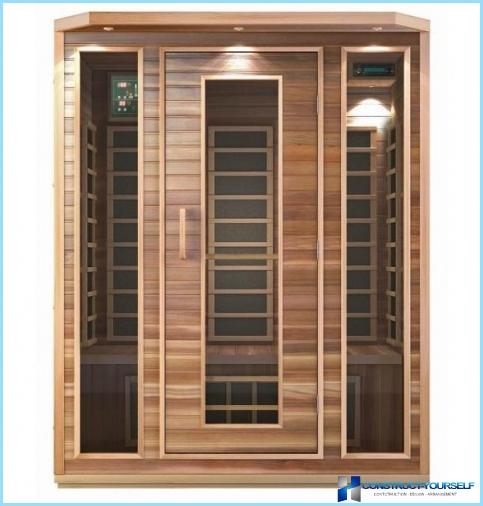

Sauna doors glass ↑

It is difficult to imagine in the Russian bath glass door. It is impossible to imagine. Although technically quite feasible.

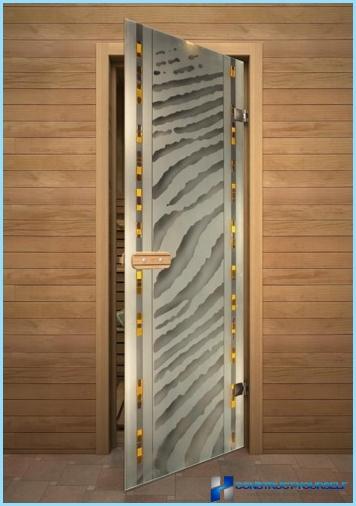

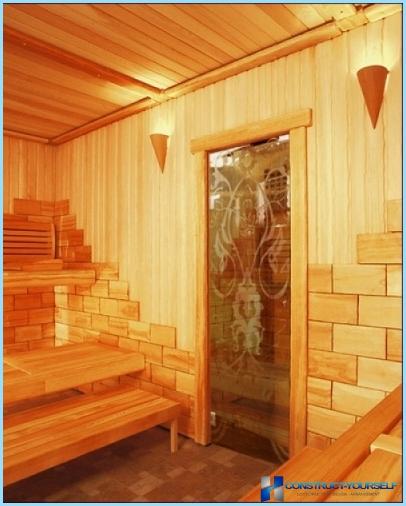

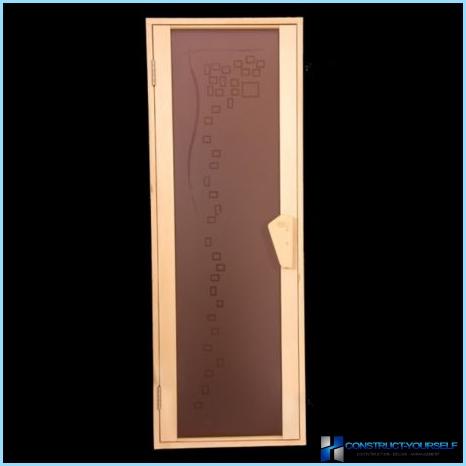

Glass doors (with glass cloth or combined) is in the saunas. They are made primarily of tempered glass thickness 8 mm. Manufacturers produce clear, frosted, mirrored, patterned. The technique of patterning is also different: the method of fusing or baking the paint in the glass etching or sand blasting method. In the sandblasting method, the part of the glass surface matira for the figure. The method of baking paint in the glass makes it possible to produce a variety of color tablecloths. Fusing is a relatively new method by which in a furnace at a temperature of about 800°C sintered fragments of glass of different colors in glass door leaf. At such high temperatures, the fragments melted into each other and into the fabric and form a single whole. With fusing you can produce very beautiful stained glass Windows. Manufacturers often use a combination of methods of drawing on the canvas.

Install glass doors are mostly in wood box made of hardwood trees. Reliability and operating quality glass doors allow you to use them without replacing for a very long time. For a Turkish Hammam in which the temperature is not very high, let the glass door in boxes of anodized aluminum.

In combined doors manufacturers successfully combine quality glass and wood. For decorative use techniques and methods that are inherent to glass or wooden doors. The combination of these techniques looks very impressive.

For the bath you can choose between buying a ready-made wooden doors, or manufacture it with their hands. For sauna glass door have to buy. But even the process of finding a suitable option will give you pleasure – so great today.