The contents

- Barn for chickens and turkeys

- Barn for rabbits

- Barn for goats

- Barn for cows and bulls

- Shed for piglets

The need to build a structure designed for storage of household equipment, of the maintenance of animals or birds on the territory of the country or the infield occurs quite often.

Building the barn ↑

In the preparation phase, you should select the location, as it is assumed that the building — is a long-term project. Everyone solves this question independently depending on the purpose of future construction.

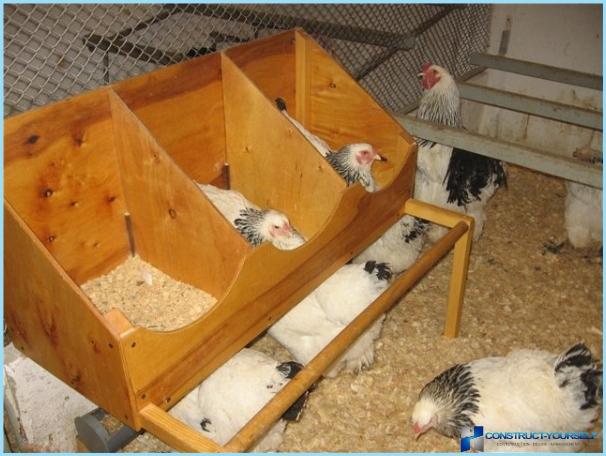

Barn for chickens and turkeys ↑

To make a shed for the chickens as the main material, choose a tree that is processed with antiseptic and insulated for the winter period. A layer of insulation in addition to walls, mounted on the ceiling. The roof is sloping. To save the roof you can use roofing felt. Arranged inside the roosts all on one level. Nests are made on the dais. Be installed additional lighting, as chickens bad rush in the dark.

A divorce not only chickens, but other species of birds. And then there is a need to build a barn for the turkeys with your hands, if it’s poultry narrowly focused. The main conditions for the bird houses – it’s warm, dry and good ventilation. The Turkey is quite thermophilic and demanding, so the area gets dry and protected from the wind. For the winter you will need heating system (water, furnace, electric heaters). If the project is long term, the construction is better to do the brick on a strip Foundation. The walls in this case plaster. The variant is more expensive, but warm – frame construction with insulation inside and both sides sheathed with boards. Roofing material for the roof may be shingles or slate. Floors should be warm and smooth. Litter are sawdust or straw. Windows are made at the top, the distance from the ceiling about 20 cm to provide a reliable thermal insulation, double glass put. The electric lighting required. From the rounded top of the bars doing the roosts in the form of a single horizontal frame. Install feeders and waterers mobile.

Barn for rabbits ↑

Often to the owners the question is how to build a separate barn for the rabbits with their hands. Mainly the different material suitable for walls. Size is immediately calculated based on the number of individuals, which is planned to contain simultaneously, since the cells are determined by individual for each animal. Approximate dimensions 65х115х60 cm and they are placed for convenience on the hill.

Still need a cage large size, which will otkazyvatsa the male and the female. For the bottom cells are used, the mesh or make it from wooden slats with a gap of half an inch. When you install the one from the other in several rows of cells provides exhaust trays. If everything to do with your hands, it allows you to control the entire process, as they have tight walls to knock down, insulate them. Be sure the device ventilation holes in the shed. Installed in the summer next to the cage using the metal mesh as fencing.

Barn for goats ↑

The desire for a healthy diet moves to have the farm animals and will soon need to make a shed for goats, which focuses on sex.

Best wooden option, sprinkled with sawdust, which is easy to sweep away. If the owner decided to make a concrete floors, you will have sawdust to pour a thicker layer. For walls of any suitable material, excluding the drafts. Can be double plank surface with foam between them.

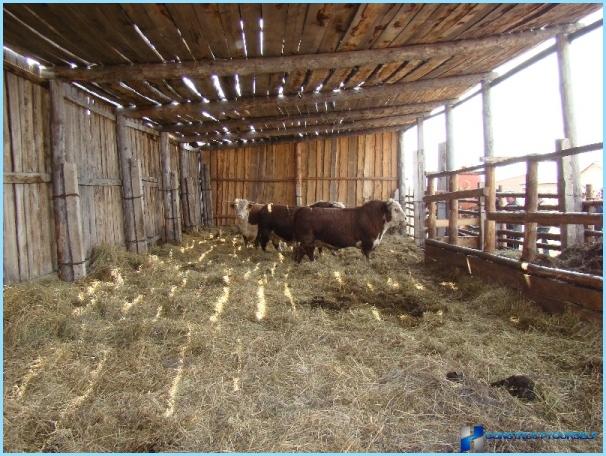

Barn for cows and bulls ↑

You often need to build a cow shed with his own hands, the material can be brick, wood, cinder block. While planning provides for the separation of partition a smaller part of the room for the calf. Begins the construction with the construction tape, concrete or rubble Foundation up to 0.8 metres deep with the arrangement of the base, on which is placed a double-layered asphalt waterproofing. Outside around the perimeter of the blind area is. A window in the barn should be, all internal surfaces bulatsa.

Fundamental differences plan the barn for the bulls has not only the area provides for more. If the content a few goals, then put stall, made of solid metal pipes. Along the aisle put a drinker and feeder.

Shed for piglets ↑

If you intend to build a shed for the pigs, at once it is necessary to provide sufficient space for of winter maintenance. The walls must be sustainable, as pigs tend to chew on them. It is advisable to use brick. Necessarily the arrangement of the ventilation, due to accumulating condensate is not formed mold and not rotted wooden roof. Floor easier to clean if it gets concrete. A separate place razvarivayutsya if contains a few animals. Large Windows not required.

Materials for barn ↑

Shed of timber ↑

You can build a shed of timber, under which is the arrangement of a pier Foundation. The construction of the tree is different from other elevated aesthetic properties, besides the tree has many well-known advantages. The insulation (three layers of roofing material) is laid a crown of wrapping impregnated with antiseptic beams connected at the corners by means of a dowel. All subsequent crowns are placed on a layer of insulation (jute, hemp). The connection at the corners «paw» will allow subsequent finishing without any extra effort. The upper rim of stacked beams, and plank floors…. The rafters are mounted in accordance with the planned shape of the roof and the presence in the attic.

Penobloki design ↑

For powerful built fit built a shed out of concrete blocks on the tape base. He settled on the sand cushion in the trench feet deep by pouring concrete into the formwork with reinforcement cages. After full preparation of the Foundation laid waterproofing, starts the block. The binder composition, a mixture of sand and cement or special adhesive which gives a more smooth and subtle seams. Each subsequent row is shifted by half the length of the block. The clutch is from the corners, verifying thoroughly all surfaces are level and straight angle protractor. It is convenient to use special corner blocks. The material is comfortable, easily sawn with a hacksaw, due to the large size, the walls are built quickly. Since the blocks are standardized, the surface is a decorative and smooth. On top of the stacked guide rail, attach the beams, rafters are established. For roofing you can use the slate, which is laid overlapping each other and fastened with nails.

The barn of sleepers ↑

Before you make a shed from sleepers, you need to determine its location. Pre-excavation carried out, the site is leveled, soil compacted. The base can be columnar, so remove the top soil and digging of pits of 0,5×0,5 m to 0.4 m in depth. Is sand-gravel cushion 15 cm each layer moistened and compacted. Cabinets can be made from red bricks with sand-cement connecting part. One sleeper roughly need three columns. If desired, the Foundation may be strip. Walls begin to build, after performing asphalt waterproofing. For fastening sleepers between use of staples. Replace them unable long nails at 200 mm, which are driven at an angle. The insulation between the crowns can be put in process of construction, and in the end to use foam.

Base — frame ↑

If you wish to have a timber frame barn which is simple in structural terms. For the frame, you can use boards, bricks, logs, or combine different materials. For example, on a brick basement to continue the work logs. Frame base are made vertical. He then sheathed with boards lapped.

The shed of the slab ↑

The easiest way is to build a shed made of slabs with their hands, for which you don’t even need Foundation. Enough to lift all the designs, setting them on the bars of the tree. After installing the bottom trim, and laying floorboards all is coated with antiseptic. The waterproofing layer is installed racks with supports and beams at the top for a roof. On the frame overlapping stuff unedged boards, most often in a horizontal direction, leaving opening for door. For roofing use roofing, fixing his straps. Inside the wall for strength on the perimeter of the fill metal tape and set the door.

A shed of corrugated ↑

If you wish without much difficulty can make a shed of corrugated Board, which would require solid foundations. In addition to construction areas, wall corrugated sheet has found its application in the construction of fences, and not only industrial facilities, but also around the country structures.

It has many advantages compared to other building materials. The market value of the corrugated sheet in the pocket of any consumer. By weight different from other roofing and building materials. Not to be a problem with the selection colors. Polymer coating of steel sheets up to 30 shades.

The platform is aligned and square removed the bottom 50 cm. the Cushion is filled with sand and gravel added and compacted on top of a thin layer of gravel. On the laid rebar filled with concrete across the area. When it dries out, on the perimeter of the concrete blocks so that their upper surfaces in a common horizontal, that is reconciled level. For future floor sets the uneven bars and the beam. Sealed frame corners and screws. Frame for corrugated sheet is made of vertical posts with horizontal reinforcing bars. The corrugated sheet is attached to the overlaps with screws. Shed out of corrugated sheets can be insulated from the inside. The roof may have one or two slopes. Gable is preferable if you need attic. The roof can be covered with a corrugated sheet having a coating of polyester. He fastened the lap with screws on the crate.

Barn of brick ↑

Capital to build a shed for villas of brick. He is considered one of the best materials for the erection of buildings of any type. It is an environmentally friendly material, easy to use and has excellent operational characteristics. The structure of brick is resistant to fire, durable will last longer. He erected on a tape, reinforced with rebar, Foundation. A good option is a silicate brick with nice decorative qualities. For the roof will require boards and roofing felt.

How to choose a Foundation for a shed?

Barn as the construction of stationary and look forward to long-term operation requires first to build a sturdy base. The Foundation for the barn is often made of ribbon. For monolithic varieties on the bottom is dug around the perimeter of the future construction of the trench is poured a layer of gravel and pour concrete. Do asphalt binding layer bituminous waterproofing mastic.

Often often the initial stage is elevated pier Foundation under the barn, because it requires less effort than a tape, and at the same time is reliable and durable. Of materials needs to store gravel, sand, rebar, cement. The easiest option for the casing is a sheet of tar paper rolled into the shape of a cylinder. Pier Foundation is the most versatile under a shed made of timber. Posts sure are planned for the building corners and around the perimeter of about two meters. A layer of soil is removed about a foot and made well using a garden drill, preferably to a depth below the horizon of freezing. Pillow is sand up to 30 cm thick. Asphalt is installed the cylinder and the armature frame, poured concrete.

Variants of construction of shed of different types and from diverse materials, there are enough. And every owner comes to their own needs and capabilities, focusing on the target destination of the constructed buildings.