The connection of polypropylene pipes using the installation fittings with different shapes. But before considering the types should learn about the features of connection of such elements.

Features connection polypropylene ↑

Due to the fact that the material is plastic, all fittings, with cut thread, do not provide the strength of the joint. If you use crimp model with slit ring, the pipe will be deformed at the point of contact and at system startup, water will leak. Also unreliable connection method is the use of a rubber gasket. In this case, the connection can withstand the flow of water, but the load on it from the outside, there is a gap.

More reliable connection method is to heat the junction to the melting point, as it leads to diffusion of the material. This ensures that all connections remain airtight even when an external impact on the system.

Connect fittings for polypropylene pipes via a special soldering iron with several holes of different diameters. The process is as follows:

- selection of nozzles corresponding to the diameter of the connected elements;

- the installation of this element in the soldering iron;

- insert the pipe into the wider part, and fitting – in a narrow.

After a few seconds, when the material begins to melt, two elements need to connect without scrolling and sudden jerks. The solidification of the material will occur as fast as the melting.

Features polypropylene products ↑

Polypropylene products, according to the statement of the manufacturers, have operating temperature range from 0 to 95 degrees Celsius. The melting of the material occurs at 175 degrees. According to the normative documents regulating the temperature of the water in engineering systems, it can not exceed 95 °. This means that penopropilen in any case able to withstand such conditions.

But it is worth remembering that during production the exact parameters are not always possible, so some items can have multiple smaller or larger wall thickness, which affects the lifetime. At the time of use also affects the water temperature. If it is equal to 20 degrees, the material can withstand about 100 years, but at the boiling point, the figure is halved.

This means that polypropylene products should not be installed in areas where there are low temperature. Specifications polypropylene pipes and fittings allow their installation in many areas.

Mechanical properties penopropilena products ↑

Penopropilen is flexible plastic, so the pipe from it have the following characteristics:

- They are not afraid defrost. If the room where the pipe temperature drops below zero, it is only a little change material, without destroying it. But because of the presence of the radiators and the boiler heating the water will still have to be drained before the temperature in the rooms drops below zero.

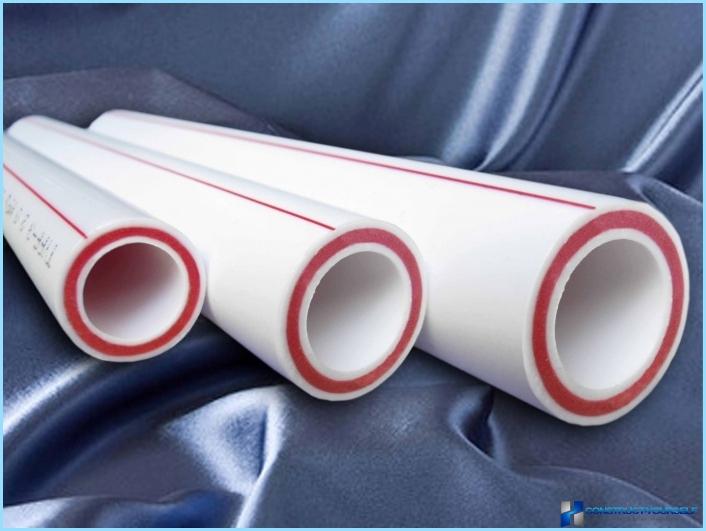

- The heat expansion. Because of this, in the open areas of the pipeline penopropilena articles can SAG or change shape. To avoid such problems is to choose reinforced products.

- The instability of stress. This means that when laying the pipeline in a place where he can influence the environment, you need to put all the elements in a rigid frame.

How to choose pipes and fittings ↑

When choosing polypropylene components of the heating system should pay attention to several parameters:

- reinforcement;

- maximum pressure;

- manufacturer.

Reinforced to withstand greater pressure, as they have a box out of fiberglass or aluminum. Thanks to this, the pipe is more resistant to physical influences. While the entire structure less susceptible to expansion when the temperature changes.

Buying tubes, you may notice a marking that indicates the maximum pressure the material. In the apartment or home installed products with the designation PN20. The same fittings are sized by diameter and have thicker walls.

If to speak about manufacturers, it is worth noting the product shipped from the Czech Republic and Germany. Often, especially in the plumbing stores you can find products of the Italian company Valtec. Buy cheap products from unknown companies is not necessary, as this could result in a waste of money on the new elements of the pipeline.

Diameters ↑

Before purchasing polypropylene fittings should consider a number of kinds of diameters of these products. But if the choice is to remember that the walls of the polypropylene tubes are thick, so the capacity of such products is lower than, for example, the metal pipes of the same diameter.

Common sizes of fittings for polypropylene pipes (in mm):

- 20;

- 25;

- 32;

- Forty.

There are polypropylene fittings with a larger diameter, but they are used only in the construction of systems that provide water to entire neighborhoods. But all products are large diameter butt stew, as the thickness of the material allows it.

Types of fittings on the issues.

If we talk about the form, it is necessary to highlight the types of fittings for polypropylene pipes:

- clutch;

- adapter;

- angles;

- tees and crosses;

- contours.

Each of these types can only be placed in certain areas of the pipeline. Couplings are used to connect two pipes and represent an item, like a barrel, an inner diameter equal to the external diameter of the tube. Such fittings are used on the straight sections of the pipeline.

The adapters are different from the couplings only in that the diameter on one side is different from this figure on the other. Such fittings can have an internal and an external thread and mounted on the ends of the risers, where the connection of the pipe member with a horizontal layout of the heating system.

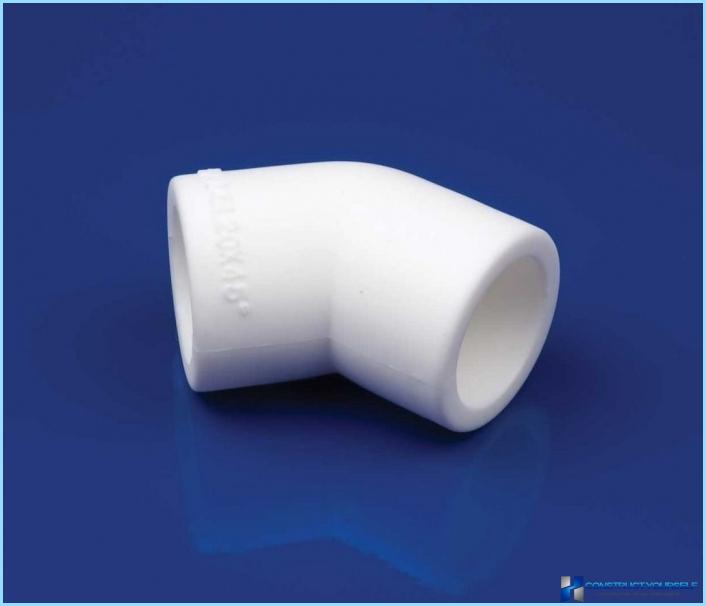

Corners ↑

If you need to change the trajectory of the pipe it can bend, but with this impact on the polypropylene product may be reduced throughput and modified wall thickness. That is why at places where pipes are connected at an angle, using such fittings.

Connection also takes place by means of welding. The corners are created to connect pipes at an angle of 45 and 90 degrees. Such fittings can be threaded and designed to connect penopropilena and metal pipes.

Elbows 90 degrees can have the following diameters: 20, 25, 32, 40, 50, 63, 75, 90, 110 mm. These fittings are produced with external and internal thread, therefore, often mounted on a connection of metal and polypropylene pipes

Tees ↑

For connecting multiple pipes are used the tees and crosses. The fittings of the first type can be used to direct water to the kitchen and to the bathroom. These products are created standard diameters and their inner diameter can be from 25 to 125 mm Connection by means of such fittings is at an angle of 90 degrees relative to the axial pipe.

The tees are of two types:

- products, axial diameter are equal, and the branch is narrower;

- fittings, the holes of each branch which are different.

The use of tees provide easy branching of tubing in areas where it is needed. To connect such fittings also used a special apparatus, the heating pipe penopropilena.

Penopropilena crosses differ from the tees to the presence of another branch and have 4 holes.

Despite all the features of polypropylene and its inability to withstand the physical loads, the products are inexpensive and at the same time, reliable. In addition, for the connection of pipes you can find many options of fittings that are easy to install yourself.