The contents

- Advantages of using pipes made of polypropylene for sewage

- Standards and labeling of products

- The assortment of products

Polypropylene pipes have high performance characteristics, is ensured by the properties of the feedstock. Resistance to the effects of external and internal factors allows you to actively use products not only in the formation of the heating system or water. The installation of the sewage system of polypropylene pipes is a promising solution providing numerous benefits over a long period of operation.

Advantages of using pipes made of polypropylene for sewage ↑

The rapid development of technology allows you to choose a material for construction and repairs with a minimal set of drawbacks and many positive attributes. Polypropylene pipes are rightly occupied a wide market segment, representing products for the furnishing of water, sewage and heating. What are the common advantages of polypropylene products:

- The flexibility and durability of the material contributes to sustainability by mechanical action on the polypropylene product. The shock may provoke a slight deformation, then the shape of the object will return to its original form.

- Chemical inertness of raw materials ensures contact of the pipe with corrosive liquids without further damage.

- Environmental safety products, including the process of waste of polypropylene.

- Temperature resistance PPR pipe is significantly higher than PVC counterparts. At operating temperatures up to 90onWith and increase briefly up to 100onWith polypropylene construction is more versatile than PVC variant operating in the range of 40-60onWith.

- The use of additives in the production of polypropylene pipes contributes to their high frost resistance, reaching the lower level of -50onC. These properties allow to use the material in the Northern regions.

- Guaranteed period of operation for 50 years is a weighty argument for the preference of polypropylene. Laboratory studies say about the likelihood of excellent use for over 100 years.

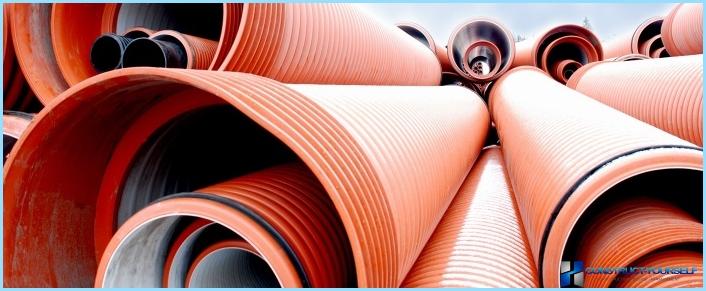

The relative softness of the polypropylene material provides a number of features in the operation of pipes for outdoor Sewerage. Traditional products are not suitable, because the soil will crush the entire structure. For the arrangement of external Sewerage polypropylene pipes are made by special technology, providing uniform distribution of loading of the soil. The method consists in creating a double-layer pipe, inner part of which is ideally smooth, and the outer surface is corrugated, which allows to reduce the pressure of the soil. When installing plumbing to use a smooth pipe due to the lack of outside pressure. Ahead of the competition pipes: polypropylene, for sewer won by the following factors:

- resistance to temperature differences and low thermal conductivity is best suited in the regeneration wastewater.

- low coefficient of friction material contributes to greater throughput than similar metal products;

- cleanliness and safety in environmental terms guarantees the absence of salt deposits and the formation of bacterial sludge within.

- ease of installation reduces construction period, the material does not require additional use of heavy equipment.

- standard dimensions polypropylene pipes, matching metal and ceramic counterparts, provide a painless replacement of the private sewer.

Due to these properties, the palm of products intended for arrangement of drain, rightfully polypropylene pipes.

Standards and labeling of products ↑

A single standard in polypropylene articles intended for arrangement of Sewerage does not exist. However, normative acts that regulate separate stages of production. According to these documents, for the manufacture of polypropylene pipes:

- we use materials that meet GOST 26996;

- is equipment sealing rubber rings GOST 9833;

- the technological process is regulated by GOST 12.3.030.

Marking polypropylene product allows you to obtain the necessary information about the intended use of the product and its operational capabilities. It reflects:

- what raw materials manufactured pipe;

- what working pressure to withstand the product;

- the maximum allowable limit temperature;

- diameter.

For arrangement of Sewerage optimally use the PPR pipe 80.

The assortment of products ↑

The diameter of the cross section and dimensions depend on the purpose of the product. According to an industry document THAT 4926 pipe systems for sewage must be released:

- Length from 2 to 8 m in increments of 1 m between sizes in some cases reach a length of 12 m.

- For non-pressure sewage systems manufactured pipe O 50, 110 and 150 mm. Most common are the first two options.

- The range of products for pressure systems more widely. Diameter in the range of 32-2000 mm, the step between sizes is one inch. Length sometimes exceeds 12 m.

Therefore, in the absence of the desired size of gauge non-pressure system apply to the selection of polypropylene pipes for Sewerage system pressurized. External drain settling exclusively corrugated products, the required throughput provided by a large diameter, it starts with 2000 mm and above. In residential and commercial buildings for internal wiring of sewer material used O 50 mm. the Thickness of the walls is 1.8 mm, the length is in the range of 2.5-30 m. sewage equip pipes O 110 mm, wall thickness exceeding 2 mm.

Types of fittings ↑

During the installation of the sewage system will be required connecting elements. All components of this series are divided into fittings for connections on glue and fittings for flare joints. Assortment of fittings includes the following items:

- Detachable bell, worn on the tube O 310 mm. is Used exclusively in industrial scale for domestic sewage is not being used.

- A reducer, is intended to connect pipes with a diameter of 50 and 110 mm. One end of the pipe is smooth pipe, and the second is a bell.

- Bends, providing an angular pair of horizontal and vertical lines.

- Tees and crosses are used in the inset of the side branches to the Central sewer system. They can be the same or different diameters. Frame is perpendicular or parallel to the plane. The ends of the parts represented in the form of a trumpet or have a smooth shape.

- Joining the two polypropylene components is carried out with the help of couplings. This section of pipe, having a length of from 90 to 160 mm, the ends decorated in the form of sockets, and the diameter corresponds to the diameter of the pipe.

In addition to the fittings Assembly procedure of sewage will require the use of two products – a tee with a plug and the compensation nozzle. Their purpose is to facilitate the installation of the system and to simplify further maintenance polypropylene construction, mounted in the wall.

Mounting options ↑

The installation of the sewage system of polypropylene pipes is easy. Even when cutting the parts, you can do the traditional knife, without resorting to the use of special tools. There are three main options for the installation of the sewage system of polypropylene elements:

- tapered joint;

- the use of welding;

- the use of sleeves.

The most common the first option when the connection is by interfacing with the use of the socket. For the second method would require special heat seal equipment. United thus polypropylene parts require no further cleaning. The process is to grip melted under high temperature of all parts. After hardening they represent a high-strength monolithic product, and the seam is almost invisible.

Installation of external Sewerage is socket connection method. Corrugated pipes are joined with sliding parts, the tightness is ensured by the use of rubber gaskets. This method ensures tight fixation with full protection against the penetration of the drain from the outside foreign elements. The lack of welding apparatus facilitates the rapid installation process that passes without action.

After reviewing the specific properties of polypropylene pipes, construction of sewage with the use of modern materials, even a layman will realize quickly and efficiently.