Sewerage is one of the most important systems that provide a comfortable existence of modern man. Therefore, its installation and repairing is given special attention. Currently, the most popular material for the creation of sewage system is plastic. This is not surprising because plastic pipe is easy to install, are light weight, long service life and are quite inexpensive. Therefore, they are increasingly replacing cast iron and steel sewage of the construction market.

Advantages of plastic sewer ↑

Plastic drains has a number of advantages that support its constantly growing popularity. So, inside it there is no layering due to the fact that she has a smooth inner surface. Installation of plastic sewage does not require complicated tools. For example, to cut plastic pipe with a simple hacksaw, it does not appear burrs, and even in the case of their appearance, they can easily be stripped.

Thanks to modern technology, plastic is used for the manufacture of sewer, very reliable and durable. Collect plastic drains with your hands you can easily and without major expenses. Using heat treatment, pipe plastic, can be bent at any angle.

Indisputable advantages of the plastic sewage are:

- light weight;

- resistance to corrosion, effect of chemicals, corrosive effluents, etc.;

- affordable price;

- long service life;

- low thermal conductivity.

Plastics ↑

Polypropylene ↑

Polypropylene is used for manufacturing pipes used in pressure sewer systems and water supply.

Characteristics of polypropylene:

- due to the fact that polypropylene is resistant to abrasion, it is ideal for sewage, grinding wastewater;

- pipe made from these materials, thanks to its light weight easy to transport and install;

- polypropylene is resistant to high temperature: it softening is possible only at temperatures over 140ºC, and the melting — 175ºWith;

- polypropylene is resistant to aggressive chemical compounds;

- polypropylene is easily destroyed during transportation, if the ambient temperature is between -5 to -15ºC. But laid in the soil pipe can withstand a lower temperature;

- state standard exists only for polypropylene pipes comprising the copolymers;

- size propylene tubes are normally determined by specifications defined by the customer. They often have a diameter of 32 mm, 40 mm, 50 mm, 110 mm;

- the length of the pipes of this material varies from 150 to 3000 mm.

Polyethylene ↑

Characteristics of pipes made from polyethylene:

- this kind of pipe is very resistant to alkalis and acids. For example, tanks that store the electrolyte for the batteries and alkali for cleaning porcelain, are made from polyethylene;

- polyethylene can easily withstand low temperatures. Freezing in plastic water pipes, they begin to stretch, and as soon as the ice plug melts away again take its original size;

- thanks to the smooth internal surface of plastic pipes in sewage does not occur the formation of deposits;

- the disadvantage of this material is its low resistance to high temperatures. But still, there are types of polyethylene that can withstand up to 80ºWith.

Polyethylene corrugated ↑

It is used in the creation of a street sewer. It is made of two layers. In the production of ribs using only the highest quality brands ПЭ63 polyethylene or PE80. Corrugated polyethylene pipe are not afraid of exposure to chemical compounds, and with the annular stiffness have the option to install to a depth of from one to twenty meters. The size of the corrugated polyethylene pipes for sewage systems is determined by the GOST 22689.2–89 and is 40, 50, 90 or 110 mm. Pressure pipes of polyethylene according to GOST 18599-83 have dimensions from 10 cm to 120 cm. Pipe whose diameter is more than 160 mm, made in lengths of from five to twelve feet. Products of a smaller diameter can be in the form of cuts, bays or coils.

PVC ↑

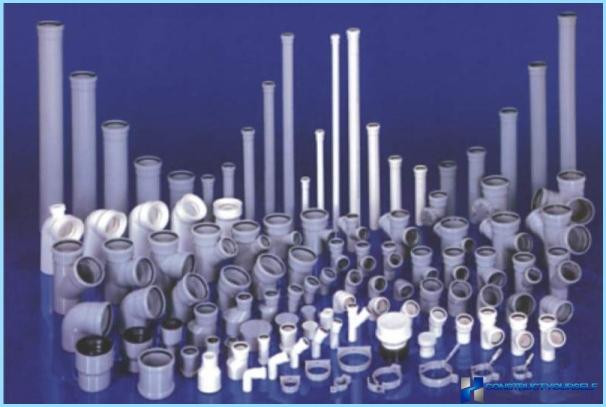

Polyvinyl chloride, or PVC, the most frequently used material for manufacturing plastic sewer. PVC water used to create new systems in new buildings, and used in replacement of old sewer systems.

Characteristics of PVC water:

- PVC is resistant to various chemical compounds (alkalis, oils, acids, etc.);

- Polyvinyl chloride is not flammable, but is deformed when exposed to temperatures from 65-70 degrees, and at a temperature of from 120ºC begins to decompose to release hydrogen chloride, so do not use this material in engineering systems where there may be high temperature;

- PVC is a insulator, meaning it does not conduct electricity, therefore, does not require grounding;

- UPVC (unplasticized polyvinyl chloride) in spite of its elasticity, when strong shock or flexing can break;

- the density of polyvinyl chloride, depending on brand can vary from 1.35 to 1.43 g/cm3.

Dimensions plastic piping ↑

Size used to create plastic sewer pipes, depending on the load on the pipeline and its purpose. For example, if the installation of the sewage system in a private house drainage pipes from sinks and baths should have a diameter of 40-50 mm, and the toilet is 100-110 mm. This is because when you drain water from the bowl, into the sewer system comes at the same time a large quantity of water, in addition, from the toilet can go to the sewers solid waste that can clog the small diameter pipe, so the bowl you should use a pipe with a diameter of 100-110 mm. the permeability of the pipe is determined by the permeability of its most narrow portion. In the bathroom the most narrow area is the production of siphon, so it makes sense to use a bath tube with a diameter of 40-50 mm.

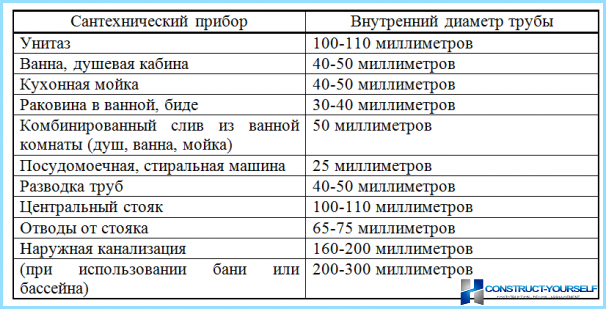

The following table, recommendations on the selection of pipe sizes for each section of sewer. These recommendations are indicative and may vary upward or downward depending on the characteristics of the sewer system and the factors affecting it.

Read more about the materials, the size and characteristics of plastic pipes, you can learn from the following video:

The peculiarities of installing a plastic sewer ↑

Consider the main features of installation of the plastic sewage:

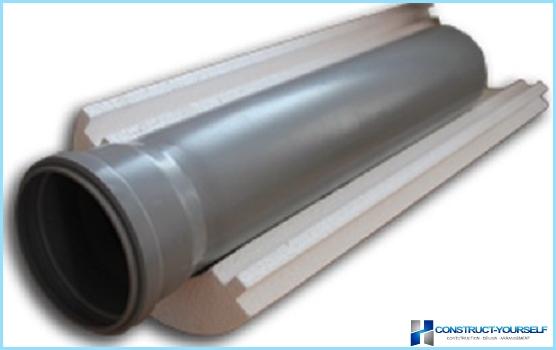

- As the plastic absorbs noise and vibration is much worse than cast iron, then installing plastic drain, it is better to use additional insulation, such as plastic box.

- Connecting the funnel with a short tube, it is necessary to remove the bevel from the outer part and the inside to remove all burrs, as even the slightest irregularities can accumulate for yourself the pollution that will cause blockages.

- If the docking of parts of the Sewerage system is required to exert significant force, it is possible to facilitate the work, using any lubrication (soap, glycerine, grease, etc.).

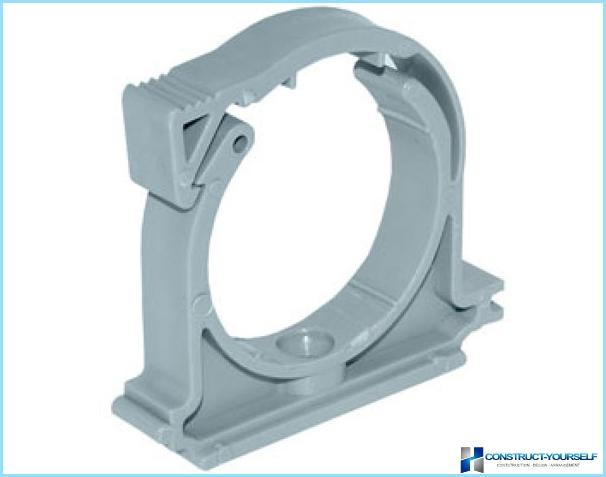

- As the pipes are made of plastic have low weight, then their fixation can be used plastic clamps and clips.

- When installing the riser cap all of the pipes must be fixed with cable ties, otherwise the joints over time can vent.

- Remember that the plastic is rather amorphous and can, over time, deform under the influence of its own weight, therefore, clamps, hangers and other fasteners should be located at a distance of not less than five feet from each other.

- To clean plastic sewage cannot use the usual steel thick wire, as it can scratch the inner surface of the system, which will lead to more blockage, and possibly to the separation of the butt sections. Soft cable with rubber tip are unlikely to give any result. The most suitable options for cleaning plastic drain is a plumbing using a cable or the analysis of the sewer system on the littered plot, as the analysis of plastic sewer, as well as the subsequent installation is a fairly simple process.

Plastic drains is advantageously differs from its iron analogue, so if you plan to create a new or repair the old sewer system we advise you to choose plastic pipe.

In order to see the process of installation of plastic sewage systems in more detail, we invite you to watch the following video: