The contents

Using any thermal equipment must comply with all safety requirements. It also refers to large installations, used in manufacturing or construction, and small equipment intended for personal use, such as home boilers.

Ignoring recommended security measures can lead to very serious consequences – we are talking about the safety of your life, and others. Therefore, the value of the safety valve to the boiler should not be underestimated, this is a very important part of his equipment, producing pressure adjustment inside the device. Unfortunately, not everyone knows about its existence or forget about its importance. Today we talk about the need of this device, the principles of its operation and its proper maintenance.

The purpose of the pressure control valve ↑

The pressure inside the boiler did not exceed the permissible limits, it is necessary to adjust it to set the safety device. What is the reason for increasing the pressure? The laws of physics, hot water expands, and therefore increases in volume. A boiler is a sealed device, therefore, the excess water can’t escape, because the drain taps closed, and drain the water back into the water is impossible because of installed equipment that regulates flow of water. Thus, hot water may exceed the tensile strength of the device, and then the boiler will explode. To prevent these serious problems and should be equipped with water heating system by valve adjustment.

Many people have a question, why to put the fuse, if it is enough to remove the reverse regulator valve with water flow? In fact, it really only works for a while. However, this option is fundamentally wrong. Taking into account the unstable pressure in the water system, no one is surprised when the water runs in a thin stream, so the pressure is very weak.

And even that’s not the worst. The water pressure can rise sharply, the water gets on the hot heating elements, a strong vaporization will increase the pressure inside the boiler, which will inevitably lead to its rupture. A few liters of boiling water and hot steam will come out, which will lead to serious consequences.

The device of the safety valve ↑

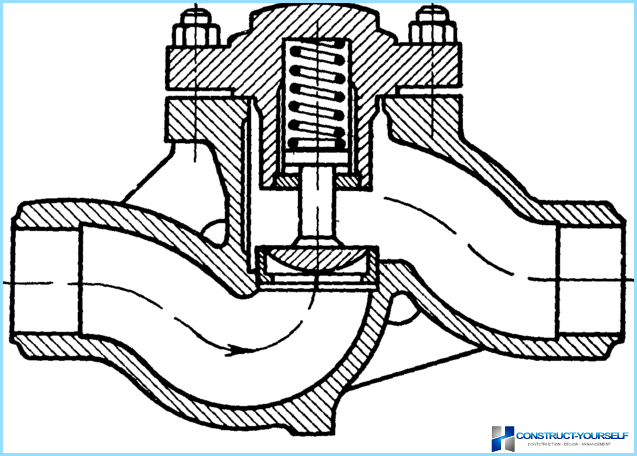

Device pressure relief valve of the boiler is presented in two parts – directly to the fuse, and check valve. Externally, the design looks like two connected perpendicular to the cylinder of different diameter.

The larger cylinder contains a check valve which consists of three elements: seat, springs and plates. The thread on this part of the device will allow you to fasten it to the inlet of the boiler.

The small cylinder is constructed similarly large, only the spring in its composition is much tougher.

Characteristics and types ↑

Safety valves for the boiler are divided into the following capacities:

- for boilers up to 50 litres;

- for boilers up to 200 liters;

- for boilers over 200 liters.

The more power a safety device, the higher its value, respectively, so it is larger and safer to adjust the pressure. In the case of fuses is not worth saving, it is better to choose more expensive and more reliable. Much easier to allocate money for a quality device, than to spend a large sum for the repair of the apartment.

Model parts and working principle, they are:

- direct;

- flip.

The first option is equipped with a disc valve, moving vertically. At the flip of a valve flap located over the saddle, and the adjustment is made its opening under the action of pressure.

Safety valve according to the type of design and principle of operation can be:

- straight;

- indirect;

- proportional.

The working pressure is determined by the manufacturer, and the bulk is produced with the maximum limit of adjustment up to 25 bar. But is made and samples are much more powerful. With the temperature mode from 0 to +250C?.

When selecting a valve, be aware that they have different threads and diameter. Thread type, step, is determined during manufacture, the diameter is basically the standard: 10-30 mm. it is Sometimes denoted in inches.

Installation of the safety valve ↑

Observing the correct mounting technology, you can be confident in the stable operation of the safety valve. Very often manufacturers of boilers equip their device with control valves in the Assembly process. But sometimes the buyer will have to decide what kind of safety valve to choose and how to install it on the boiler. There are some nuances, for example, water heater Termex can be equipped with valve only by means of the adapter specified diameter.

But there are General rules for the installation and adjustment of safety valve for boiler:

- Before beginning installation determine the direction of water movement in the valve (it is specified on the body of the arrow).

- The unit is supplies power to the pipe.

- The installation is performed on the area between the water heater and shut-off valve.

- Seal threaded connections FUM-tape or flax.

- Tighten the connection without excessive effort, but at the same time, tight enough to avoid leaks.

After the installation of a safety valve for a boiler is made, you need to apply water and check all connections for leaks. If the connections pass water, adjust – tighten them stronger. If this does not bring result, it is necessary to dismantle the safety device and even better sealing threaded connection with a new layer of winding.

To test the valve, simply open the drain hole. If water runs, then everything is fine. But some manufacturers, such as a safety valve for boiler Gorenje, produce their device a little different design. Therefore, to test the ability of the pressure control is necessary according to the instructions of the manufacturer.

Faulty valve and its adjustment ↑

With safety device, can happen one of two things: either it not flowing water, or Vice versa, dripping very much.

To understand the principle of operation of the safety valve, clarify that normally, when heating water, you can adjust the pressure and the water is discharged. This can occur when the boiler is switched off, i.e. does not heat water. This is because the limit of operation of a safety device below the pressure of the water in the water pipe, that is, if the device can withstand up to 6 bar and the water supply delivers water at a pressure of 7 bar. If bleed water for this reason is commonly it is possible to equip the water supply system of the special reducer. It may be easier to install it immediately on entering the water in the apartment or house. But you can choose a small model and put directly in front of the boiler to adjust the pressure in it.

Inspect the valve is another way. Turning off the boiler several times to raise and lower the lever the emergency release of pressure. Water stops dripping from the safety valve of the boiler, and will drop again when start heating.

If water continues to leak from safety valve for boiler, then this may indicate a blockage of the device. Folding model need to be removed to be cleaned and put in place. Non-separable variant can only be replaced.

Of course, the constant dripping of water unpleasant sight, but it is not dangerous. But if the increase in pressure in the pipe opposite the water does not appear, then most likely clogged fitting conclusion himself or the safety valve. You need to clean them, or replace, if this doesn’t help.

Conclusion ↑

Deciding to choose and install safety valve for boiler, approach it with all responsibility, define the required settings and proceed with the installation and adjustment precisely in accordance with the regulations. If you doubt your abilities, leave this work to professionals.

How the scheme is to wire the boiler, find out in the next video