As the screed is happening with greater difficulties than pouring self-leveling floors, despite the fact that the device both surfaces are the same, the second option was used more often.

These floors are characterized by a mixture of savings and relative ease of installation, whereby the involvement of specialists from the is optional. When selecting something specific is important to understand how powerful will load in the room, as some coatings can not withstand the frequent patency.

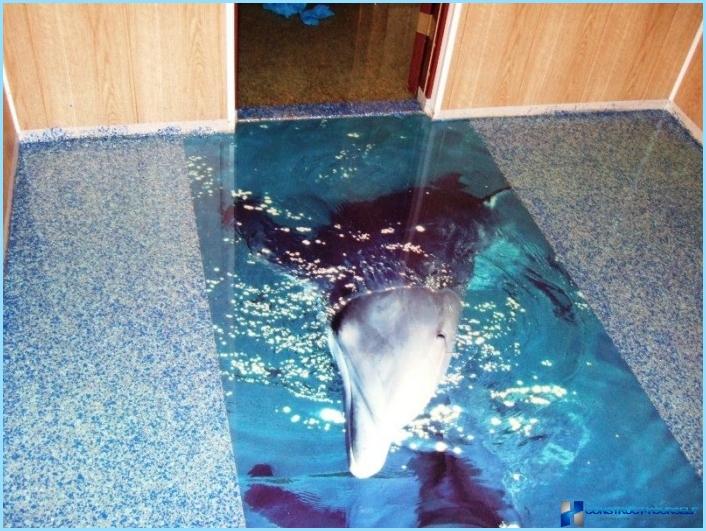

The main difference of the sexes is similar in their composition: Yes, polymer flooring, a binder which is a polymer and has a coating mixes consisting of sand, cement and plasticizers. There is a one-component flooring that you can lay decorative materials, and two component having an insert with images.

The pros and cons ↑

Before you start pouring self-leveling floor with their hands, you need to understand the strengths and weaknesses of such coverage.

Among the advantages we can note the perfect alignment of the floor surface, maintaining the original appearance for a long time, immunity to mechanical or chemical attack. Natural factors such as fungus and mold are not dangerous, as the flooring is seamless, and the spread of bacteria can’t. When heated, do not stand out toxic fumes.

Paul is not afraid of moisture, and it is very convenient to clean up. All of these benefits make screeds are suitable for use in establishments for medical purposes.

As for the cons, they are the following:

- To prepare the base is problematic, and the process takes a lot of time.

- Potential repair or replacement is accompanied by some difficulties.

- In close proximity to a radiation source of ultraviolet radiation such mixture can not be applied.

- The material cost is relatively expensive, and the variability of the colors and the drawings leaves much to be desired.

The choice of a mixture of ↑

Each blend has its own operating characteristics, additionally, there are your requirements on thickness of application, time of curing etc. There is a cement mixture that dries not more than 5 hours, and applied a layer of 5 mm is Used in all types of premises.

A mixture of plaster at a cost cheaper than the previous version, but they can’t be used in wet areas. The thickness may not exceed 100 mm. There are quick-drying formulations, which are stacked in a 15-minute delay will lead to the fact that the floor will harden.

You also need to consider the filler mixture, in particular, the size fraction. A large fraction is used to create bases, respectively, such mixtures are applied in a thick layer. For correction of small defects is fine compositions. When strong defects is used and a rough dry mix and leveling the mix, in all other cases will be leveling mixture.

Work order ↑

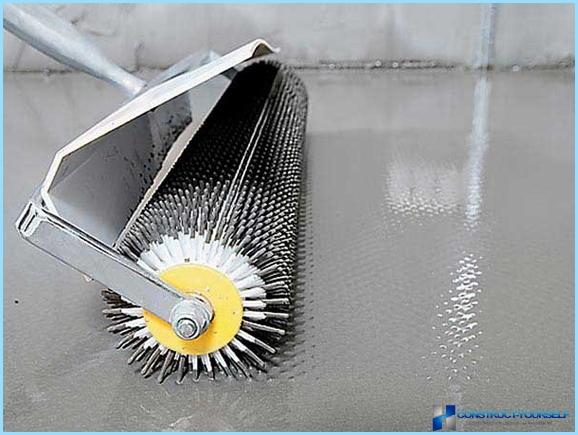

To complete installation you will need to get a building by mixer or electric drill to mix the compound and water. Water need to get a capacity of at least 20 liters a spatula to work in the corner and spiked roller.

To prepare, you’ll need to get rid of debris and dust, all existing cracks to widen to a width of 0.5 cm, to the mixture without any problems filled out all the problem areas.

Concrete floor initially has not a very high-quality adhesion of such mixes, so you should handle it with primer deep penetration, allow it to dry and then start shading.

Preparation of a mixture of ↑

In a clean bucket filled with water and poured the powder in the proportions specified on the package. Construction mixer, briefly mix the composition with one-minute breaks. To do the kneading should until no lumps.

Quality control of the mixture may serve as the cap of aerosol, with the same height and diameter. After cutting the bottom, the cap is placed on the glass, and then poured back part. You need to look at the diameter of the resulting spot of liquid, if it is in the range of 16 to 18 cm, then it is a normal density. If it more, it is added to the powder and knead again.

Fill ↑

It all starts from the wall, which should be as far from the door.

Alone all perform difficult, so you should take assistant. Some people will cook the filling and the second to upload. Theoretically everything can be done alone, but you must then act quickly.

Liquid bottled or strips go zone, if the floor will have a different color. The direction should coincide with the starting wall. Then comes the alignment of these bands of a wide spatula, taking into account that the thickness will not be more than 5 mm.

Now you go to remove air bubbles with a needle roller. During this process, the coated surface will have to go, and this should have krasotami.

When everything is ready, is to cover everything with a film of polyethylene to keep dust and dirt. Waits the period of 5 days, after which self-leveling floor with their hands varnished, and these layers should be several. Apply polyurethane varnish applied consistently. This will make the surface nice looking gloss.

Applications ↑

It is very important to decide what kind of a place in the house to decorate such a coating. There are places where such floors are more relevant, there are places where they look not so preferable. If we are talking about bathroom, then this place is a good to do this for the first time. Here it is necessary to speak not only about the initially small size of the premises, and that the operating characteristics of the floor are very suitable for the bathroom as moisture coating is not afraid.

The same is optimal and kitchen, for which the glossy finish will be very easy to care for, so as to wash it is simple enough, and it can fit into any type of interior.

An unusual solution is to level a floor self-leveling mortar with his own hands in the hallway, if the initial cover in tatters. It may be performed to reduce the estimate, when instead of a few plates filled with such a mixture, and the rest of the cover is standard. The location of loading zones must be in the same place where most go.

Care, as has been said, is limited to ordinary detergent and wet cloth, the frequency of care is at the discretion of the owner.