The contents

Parquet Board was invented in Sweden in the 40 twentieth years of the last century by Gustave Cherom. Currently, it is a wonderful alternative to conventional flooring and is gaining popularity among consumers. So, in Europe it is the reason more than half of the hardwood floors. The reason is that such a coating has all the properties of the flooring, but it has a lower price. Next, we analyze the properties and characteristics of the parquet boards, parquet compare boards from different wood species, and will produce a review of the popular manufacturers.

The structure of the floorboard ↑

The floor consists of several connected to each other, layers of different wood species. Usually these layers do three. They are perpendicular to. That is, the wood fibers of the top layer runs along a Board, the middle layer is wide, and the lower again along. The top layer can be from 0.6 to 6 mm depending on the manufacturer and the layer is made of valuable tree species that have appealing texture. For the middle and lower layers typically use less valuable species such as larch, pine. Such structure provides greater longevity and lower cost compared to the parquet. Parquet top is treated with lacquer or oil. Floors made from this material practically does not distort its shape in extreme temperatures and exposure to high humidity.

Types of parquet boards ↑

Parquet Board can be wood used in their creation, coatings, dimensions, number of planks in the working layer (lamella).

As the upper layer is used as a traditional tree species, and exotic. Traditional breeds ranked: oak, maple, beech, ash, cherry, birch and exotic wenge, merbau, Tali, Jatoba and others. Used in the manufacture of wood affects the colour, pattern and hardness of the floor covering.

The color of this flooring can vary from almost white to black. The shades depend on the method of processing the material. So, the treatment of «antique» artificially ages the wood and gives it a noble tone, bleaching gives a whitish tint, and steaming, on the contrary — a more intense color to create a surface effect of the ribbing used method combing.

As a coating for parquet Board can be used as varnishes, and oil mixed with wax and resin. Most often use acrylic paints, making the surface smooth, flat and durable. When using oil, the surface becomes more vivid and intense, but has less wear resistance than lacquer. There is a coating manufactured by Tarkett, giving the surface the same appearance as when applying the oil, but provides the Board greater durability.

Another characteristic is the number of lamellae (strips) on the outer layer. There may be from 1 to 3. The smaller the divisions, the more valuable the material, because the Board with one stripe looks like an array.

The size and price ↑

As mentioned above, the parquet boards are different thickness and strength of the outer layer, as well as dimensions. The total thickness of the Board ranges from eight to twenty-five millimeters, and the thickness of the top layer ranges from 0.6 to 6 mm.

The width and length of boards is determined by the manufacturer. Usually they are in the following range: width from 130 to 200 mm, length from 1800 to 2500 mm.

The price of the Board depends on the thickness and the values used for the outer layer of wood, and the popularity of the manufacturer. The floor covering in the manufacturing process which used exotic tree species, always have the cost is much higher than that made from traditional hardwood and plank in half to two times more expensive than three, consisting of small laths. The average price can range from 20-60 to $ 95-110 per square meter.

Feature of wood working layer ↑

Consider the characteristics of the most common trees used for the production of top layer parquet boards.

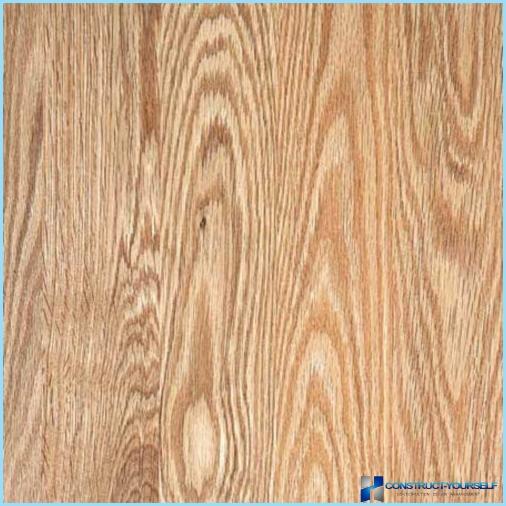

Oak. Of the traditional types of wood are best to create a working layer. It has high strength and nice texture, resistant to various external influences, almost not expanding and not shrinking. Has a wide selection of colors: from black (bog oak) to brown green, light brown and even white. This fine material having a relatively high cost.

Ash. Colors are represented by different shades of yellow. The main advantages are: ease of processing, flexibility, strength.

Beech. In its properties beech is close to the oak. Well gives in to polishing, processing, has high strength, not prone to cracks. Has a smooth, calm texture, often pale-pink color. But coloration can vary from light yellow to deep red. Suitable for those who prefer solid floors, almost without texture, with warm color. The disadvantages include incompatibility with the system «warm floor».

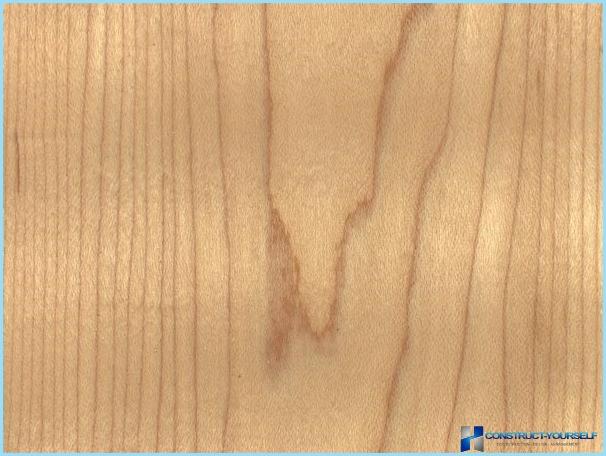

Maple. According to its characteristics play previous content. Sensitive to temperature changes and high humidity. In the process of operation changes its light color to dark honey.

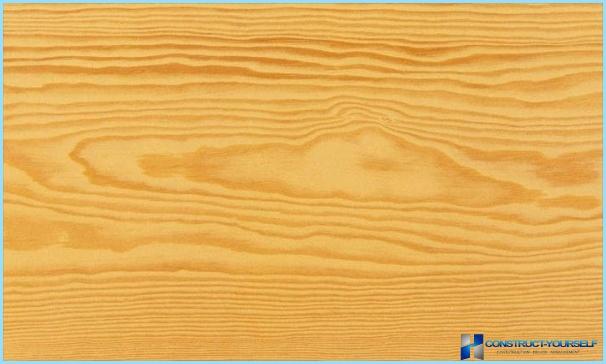

Pine. A very popular material for flooring. Has a high thermal conductivity of the air. This is an inexpensive option that allows you to create a cozy atmosphere in the room. Has a warm red-yellow hue, changing under the influence of sunlight on red. The structure of this material is quite homogeneous. It is wonderful to finish due to its softness and high gummosity this material provides durability.

Walnut. Has a clear deep texture. Is characterized by resistance to high loads, deformations and cracks. Perfectly treatable and polishing.

Bamboo. This material is the most environmentally friendly. It has high durability that exceeds even the durability of oak. Perfectly withstands high humidity and temperature changes, is not prone to cracks and deformation.

Popular manufacturers ↑

Let us examine the most popular manufacturers on the domestic market.

Leaders in the production of laminate and parquet boards in Europe are the Scandinavians, for example, the firm Parkett Tarkett. It has existed for two centuries. Currently Parkett Tarkett is the official provider of flooring to the court of the king of Sweden. This manufacturer gives its products a warranty of 30 years! In addition, this company owns the invention of several types of lacquers, coatings, locks flooring.

In the five of the largest manufacturers of flooring in the world includes firm BARLINEK. Its range includes: wooden staircases, laminate, parquet Board, parquet. The basis for parquet Board BARLINEK are from coniferous trees, arranged in two layers, so that the fiber direction is at right angles to each other. These layers are lined with fine wood and treated with several layers of primer and lacquer. For drying lacquer and primer are used ultraviolet rays. BARLINEK offers a wide range of patterns and colors of the working layer. So you will be able to choose a shade that is perfect for your room and furniture, located in it.

High demand production of the Finnish company Upofloor, which exists in the construction market for over a hundred years. During this time, the master Upofloor has thoroughly studied all the features of their craft and deliver on the construction markets of the goods of the highest quality. In addition to high quality, Upofloor flooring firms differ and amazing warm home and is able to create comfort in any room.

Domestic manufacturers stands firm Karelia. This manufacturer presents a wide range of parquet boards from class «economy» to class «premium», it allows choice of material not only any taste, but every budget.

Also popular are the floor covering, produced by the German-Russian company Alpenholz. German technology combined with the skill of Russian Cabinet-makers enabled the firm to achieve greater success. For the manufacture of its products Alpenholz uses of tree species that grow on the slopes of the Caucasus mountains, as well as some exotic wood species. Parquet Board from Alpenholz has a fairly low price, which ensures its high demand.

Operating tips ↑

- To care for this floor covering is recommended to use a vacuum cleaner because the parquet flooring does not tolerate moisture, dust and sand, which can fall through the cracks.

- Wash this floor should be only slightly wet, well-wrung cloth.

- Also for cleaning you can use special means, which cleans the surface and increase its lifespan.

- In contact with liquid on the floor should delete it as soon as possible to prevent flow into the cracks.

- With the appearance of mechanical damage to the floor must be restored by sanding and then varnish. As a result of this procedure, your flooring will look like new!

Also on the characteristics of the floorboard you can see from this video: