The contents

The choice of flooring is an important step in the construction of floors in the house or apartment. And depends on what materials have to use the interior space. And since the tree has always been the most popular material, many people are still trying to use the floorboard.

Depending on the professionalism of the paver flooring directly determines the service life of such coverage. In addition to the installation of the floor can not hire artists, especially if you have the opportunity to perform all the necessary work himself. Due to a phased plan, you can easily install the floor on their own.

The types of parquet boards ↑

Traditionally experts klassificeret floorboard on the number of lanes that are visible on the decorative layer. In accordance with this classification it can be:

- SSB. In this case, due to the special technology it has become possible to manufacture panels of solid wood, preserving natural wood texture.

- Two-lane. In this coating a base made of one-piece or composite fabric. The final layer is created from two planks.

- Three-lane, where the panel design consists of three fragmented bands.

The benefits ↑

Wide application of the floorboard due to several important reasons such as:

- higher resistance to external influences compared with natural wood veneer;

- the surface treatment in the factory special protective compounds and no need for additional processing;

- lower cost in comparison with natural parquet;

- no need for sanding.

However, as with any finishing material, parquet panel has also some disadvantages:

- because the texture of the Board has a one-way direction, forget about the figure the floor covering;

- has high moisture resistance, so it is necessary to take additional protective measures.

The initial phase ↑

Deciding to use a parquet panel should calculate the area that you want to make, not to buy extra material. Next, you need to examine the Foundation for cracks and potholes, as well as the presence of bias need to create additional ties with cement sand mortar.

In case the defects are not significant, it is possible to use a conventional substrate. Direct the paving is performed on pre-fixed plywood sheet on which to create a vapor barrier is lined with a special cardboard. In this case, apply an undercoat. Also, very often when stacking is used, and a cork backing with a thickness of 3-4 mm.

The methods of installation ↑

Parquet Board can be laid in the following ways:

- floating;

- glue.

In the first case, the connection between panels is performed by means of special technology of interlock, making installation or dismantling is very easy.

The second method involves the use of adhesive to connect the flooring to the substrate. It is necessary to apply the adhesive along the entire length on the bottom grooves of the Board, and if the installation will be carried out diagonally, but it is from the corner of the room.

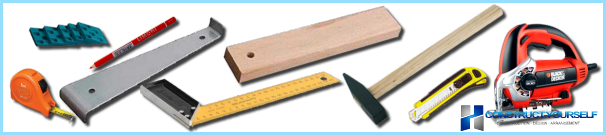

The process of installation takes one day and requires a minimal set of tools, namely:

- wood saw or jigsaw;

- plastic bar kit and hammer;

- clamp and lock wedges;

- square and level construction;

- roulette.

The basis and the device flooring ↑

For quality flooring wood flooring without adhesive bonding requires that the Foundation was sturdy, clean and smooth as possible. There are two types of foundations for floor – concrete screed and wooden floors, with height adjustment.

Concrete screed should be no significant differences, otherwise the floor will creak. And hardwood floors with the possibility of height adjustment allow you to raise the surface to five or more inches, which gives you the opportunity to save time on the device and lay underneath various communications.

Before you begin installation of the floor covering material should be Packed to leave for 2-3 days indoors where it will be repaired. Underneath the panels you need to lay cork or synthetic substrate, which will protect the Board from excessive moisture, which the joints are subjected to the additional sealing.

First there is the device for the first two series, which must be installed parallel to staring out the window at the rays of daylight. To do this, along the walls, you must first install the special wedges, and lay the first panel in a checkerboard pattern. The clearance should be at least 10 mm. This gap is the compensation seam, which helps to protect the floorboard from mechanical stress during the expansion of the material in case of changes in temperature and humidity.

After laying and pressing the wedges of the first two panels, it is possible to start installation of the second row. Length closest to the wall panel, the second line should be at least 80 cm ideally, the transverse seam of the first row is exactly in the middle of the floorboard’s second. The distance between the transverse seams parallel rows shall not be less than half a meter, otherwise the panels will be fragile.

Further, the panel of the second line included in the locking mechanism of the floorboard in the first row at an angle of about 20?, but not fixed. Similarly, the next panel is inserted in the second row, but snaps and egged together with the first Board in the castle compound. After parquet boards with timber will be fitted to each other until the disappearance of seams, they are fixed similarly the laying of all floor space, except for the last row.

Styling last parquet panels need to accurately measure the distance of the edge of the penultimate number to the wall. Panel of the last row to create the compensation gap should have a width of 10 mm less than the measured distance. After the grooves of the next to last row should be cut from the outside edge, fill with glue and insert the last row of the panel. Tightly insert the last row of the Board by the mounting legs, which comes complete with parquet.

At the last stage, perform the installation and fixing of skirting boards, which should remove all wedges. Mounting plinths comply directly to the wall, and they shouldn’t tightly pressed to the floorboard. When choosing a floor you should consider what width it should be easy to cover the expansion gap.

Which is better: parquet, parquet Board or laminate ↑

Laminated parquet Board is the most popular now types of flooring. Both of these finishing materials allow to obtain durable and reliable coverage, and sometimes they are so similar in appearance that the person far from the building it is difficult to distinguish between them. So, what is the difference between parquet and laminate?

Production. Laminated panels for floor covering can be compared with the desktop, moved on a laminated fiberboard, while parquet boards – three layers of natural wood glued perpendicular to each other and two of which are made from cheap raw materials, and the upper face only of precious wood.

Appearance.Laminate often has a imitation of natural wood, but all the bars have the same pattern. Parquet panel is different, because the picture on it is identical to the natural structure of wood, and two identical panels just did not find it.

Practicality. Laminate flooring, with resistance to abrasion is more practical in comparison with parquet. Parquet panels are in need of more respect and do not tolerate high mechanical loads and temperature extremes and fluctuations of humidity.

Particular care. If you plan the device of floors from parquet boards in the kitchen, you should immediately buy a special care. If the floor is cleaned with MOP, it should be slightly moist, and the use of the vacuum cleaner is not recommended to enable «couples». Also sensitive to humidity, and laminate, but not so hard as wooden Board. Not recommended for use and household chemicals.

A lifetime. Parquet panel only on the surface may seem like a fragile material, but if it appropriately to care, it can last up to 30 years. Moreover, the floorboard can significantly increase the lifetime by periodically carrying out the restoration, but not more than 4 times in all the time. Laminate will last 7-20 years, but with a higher class of durability, it last longer.

The cost. High-quality laminate is not much different in price from the floorboard, so choosing one or another floor covering, take into account the properties and peculiarities of space, which will be laying.

Experts ‘ recommendations ↑

Flooring it is advisable to choose from well-known manufacturers because of the good geometry of the panels.

It is not necessary to perform flooring parquet panels in areas with high traffic, for example, in the hallway, as the floor restoration will need to do much more often than in the living room or bedroom.

The installation of the parquet panels should be performed at 18-24?C and humidity around 30-60%. In this case, the flooring will last a very long time.

Before to start works on the device floor coverings, parquet panel, you must leave for about 2 days in the room where the floor will be laid.

When laying boards near the walls create a special gaps of a width of 10-15 mm for expansion joints, since wood can expand with humidity changes and temperature, and this measure will allow to avoid the inflated coverage.

Lock connection between floor boards can be considerably easier if you lubricate the locks wax or paraffin impregnation. Sealants in this case should not be used.

Laying should start from the doorway, moving to the window.

Following these simple tips will allow the coating of parquet panels last as long as possible.

How much is the installation ↑

The price for work on laying depends on the way of installation is about 9-10$ for 1m? for «floating» floor and adhesive option on a cement screed will cost around 13-14$ per 1m?. This is because when the adhesive method of placing all necessary materials.

And at the end we present the video lesson, which shows all the technology, phased installation of parquet boards