The contents

Currently when decorating the floor and use a traditional whiteboard, and modern flooring. Among the popular materials landscaping floor-select parquet Board having the special locking compounds.

To increase the useful life of the decorative coating, elimination of unpleasant creaking, you need to lay the boards on a flat surface. Also, it is important to use a special substrate under the parquet Board which performs the functions of sub-floor.

The purpose of a lining material ↑

The base, which fits on the floorboards, maybe with a bias, flaws, cracks, imperfections. These shortcomings lead to the fact that appears empty, over time, the following situations are possible:

- cracking and disintegration of the dies;

- low depreciation, the appearance of noise while walking;

- the occurrence of creak;

- damage the connecting locks between the boards.

Parquet Board has a sufficiently high value, so homeowners are looking for ways to increase its service life. To increase the operating period of the floorboard, with the laying of this material, it is important to use a special levelling coating material under parquet and laminate.

This material performs the following functions: sound insulation, heat insulation.

Choose a substrate ↑

The selection of the basis under the flooring, pay attention to several key indicators, the coverage was for many years.

First, it is important to pay attention to the thickness of the selected material. Experts believe that the optimal thickness of the substrate 2. It is this value that is a valid difference of height floor to floor. In the process of operation, regardless of the quality of the material will occur at the seal. When choosing a substrate of substantial thickness, the difference exceeds 2 mm, the result will appear creak of the floorboard, the backlash in the joints of the boards, the deformation of interlocks.

Second, take advantage of the ability of the substrate to level the ground before laying parquet boards. If there are significant irregularities, just use a levelling mixtures with gypsum-fiber Board, moisture resistant plywood as a backing problem you decide.

Third, pay attention to the resistance of the substrate to high humidity. In addition Topleka, the substrates produced on the base of bitumen mastic having a porous structure, good moisture-wicking.

Principal substrates ↑

Currently, the construction market offers several types of substrates under the laminate and parquet Board:

Cork underlay. This material is the only natural and environmentally friendly. Experts believe the cork is the classic material used to make a substrate under a parquet floor.

If you choose this substrate, pay attention to the thickness. Best option coating thickness – 2 mm. With a smaller thickness tube may crumble, and for greater thicknesses, it is possible destruction of the tool joints between floor boards.

Among the advantages of this substrate note: sound insulation; heat insulation, environmental friendliness, naturalness.

The main disadvantages of cork substrate are the instability to moisture (swelling) and high material cost.

Penopropilena substrate for parquet floors flammable and toxic, it is better not to use in a residential area. This material has properties similar to polyethylene, but between the substrates, there are differences: minor operational period (7-10 years), and gradually turning to dust.

Polyethylene foam underlay is the most affordable. Polyethylene foam manufacturers offer different thickness for parquet Board select option – 2 mm.

The porous structure of this material provides the following characteristics of this material:

- good insulation;

- excellent soundproofing;

- quality insulation;

- resistance to high humidity;

- the lack of decay;

- resistance to aggressive chemicals;

- mechanical strength.

The polyethylene foam, there are the following disadvantages: low fire resistance of artificial origin, a significant shrinkage in the process of operation.

Parcolag. Parcolago good performance, the disadvantage is the high toxicity when heated. This framework is made on the basis of bitumen mastic.

Among the advantages of the material include the following: insulation, thermal insulation, moisture resistance, affordable price.

The downside of the material is the toxicity of the bitumen. When the temperature is the emission of formaldehyde (metanola), a powerful poison. European countries refused from such material, aware of its dangers to human health.

Duplex. This material is considered a universal multi-layered material with excellent performance. The artificial material consists of three layers, each has its own function: the bottom layer, middle layer, top layer.

The bottom layer is a porous film. Its main purpose is to bond the middle layer, the transmittance of inside moisture. The middle layer is made in the form of small balls, which helps the material to maintain elasticity. The role of the fan to fulfill the gaps that are between the balls. The third layer is made of a conventional plastic film. Its main task is the vapor barrier.

The lining of Tuplex experts recommend for any flooring. It laying can be carried out on the concrete floor, not paying attention to humidity. With the help of the air layer, which is in Tuplice, is the removal of moisture, its evaporation through the gaps left between the parquet flooring and the wall.

For each, there are some positive and negative characteristics, so look for the best substrate under the parquet Board will have, given the financial possibilities and personal preferences.

Algorithm ↑

The proposed sequence of steps associated with leveling the floor before laying parquet or laminate:

- No matter what kind of flooring you choose, you need to spend leveling the subfloor. To level the subfloor by using special leveling compounds or cement screed. Additionally you need to treat the floor surface with a grinding machine.

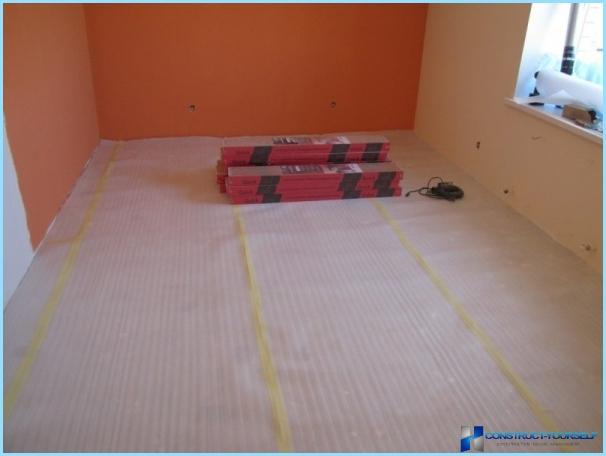

- Once the base is level, you need to apply primer or vapor barrier layer. Only after that can be laid on the surface of the substrate under the flooring.

For the parquet, the necessary rigid fixation plates with the base, so used the adhesive version of the installation of the floor covering. Water-resistant plywood or particleboard is glued on the concrete floor, additionally fixed with screws or dowels.

The lining under the flooring is suitable for leveling the subfloor. For a lining material needed sheets with thickness from 8 to 20 mm., Their styling is carried out with a clearance to prevent swelling of the coating when sudden changes in humidity or temperature. Sticking to the draft framework of the parquet planks is carried out using adhesive or special postmark.

When laying parquet boards using the floating method. It does not provide a clear grip and base flooring. The substrate in these situations will be the materials with certain characteristics: polyethylene foam substrate and foil materials.

Conclusion ↑

It is impossible to distinguish among the substrate under the parquet Board, presented on the construction market, the best option. The choice is connected with the possibilities of the budget, personal preference. Note that it is possible, it is better to buy natural substrate, safe for health.