The contents

Probably the main difference between man and animal is that he always wants to cheat nature. This is manifested in all actions and behavior, and this often becomes the main engine of progress.

I touched it and agriculture. The little man that gives him nature, but rather, he wants to bear fruit all year round, not just during the season. For this, many country houses or backyards build greenhouses to grow fresh vegetables in winter will need more complex design with heating system and ventilation.

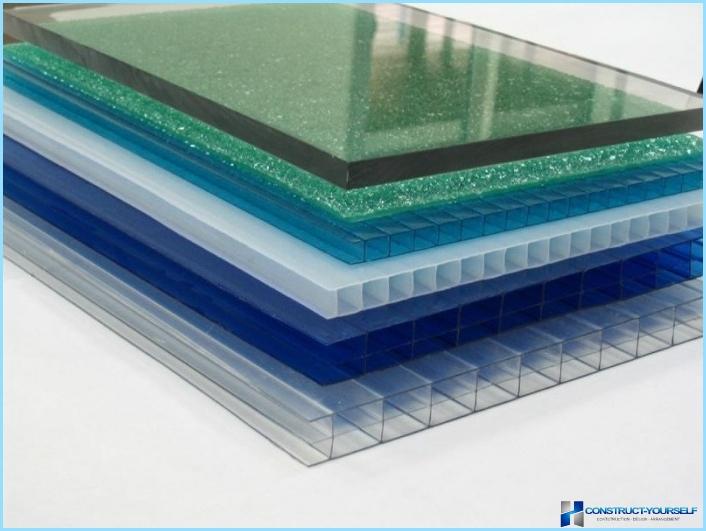

But you can do a simple design and to obtain from it products several months earlier than it appears in the markets. Materials for greenhouses and hothouses are several, and each has its drawbacks:

- Plastic film, keeps the body warm, but comes into complete disrepair after a maximum of two seasons.

- The glass is long, but creates the effect «magnifier», often burning the crop.

- Geotextile for greenhouses, is somewhat longer than film, but the greenhouse effect is much less.

Today, more and more, as covering material for greenhouses, the use of cellular plastic. Polycarbonate greenhouses with galvanized profile are considered to be most durable, reliable, and durable designs. And about how to build a greenhouse yourself and save money on builders and would like to talk.

What to collect greenhouse ↑

Greenhouse is not only the material, which it is served is much more difficult to assemble the frame, because it will depend on the strength and stability of the whole structure. Especially if we talk about stationary greenhouses, which are not dismantled for the winter, and so they will be snow to create a potent stress on the surface. The greenhouse will constantly test the strength of the winds and rains. And all these adversities she must confront.

As a material for the frame, you can use:

- Wooden beams.

- Metal pipe.

- Galvanized profile.

The latter option is the most preferable, as the tree quickly crack and unusable. Metal pipe though and will last longer than galvanized profile, but it is expensive and its installation will need welding. Moreover, due to the large weight, the greenhouse is almost impossible to move to another place.

The frame of the greenhouse galvanized profile is devoid of all these drawbacks and in addition has a number of advantages:

- Easy to install and requires no special skills in construction.

- The set of tools needed to assemble the frame of galvanized steel profile there almost every summer resident or home worker.

- Galvanized coating does not rot and does not require additional painting and regular ponovleniya.

- The design is very lightweight and if necessary can be moved to another location.

- Galvanized steel profile is much cheaper than metal pipe and for private greenhouses is an important factor.

- The speed of the construction of the profile frame. Even in the absence of skills and experience, to complete the construction will take only a few days, and if the experience is still there, then a few hours.

By the way, today you can find ready-made factory of the greenhouse galvanized profile. They consist of prefabricated modules and assembled on site as the children’s designer. Of course, the cost of such a greenhouse will be more expensive than homemade, but in some situations – this is the best choice.

This can be done with a simple reinforcement length of not less than a meter, which is hammered into the ground through the body of profile, walking on the ground. To hammer the pins need not less than a meter apart, then the design will be firmly attached and can’t flip it over a strong gust of wind.

Collect frame ↑

As with any construction, Assembly frame greenhouse galvanized profile with your own hands, start with the calculations and preparation of all necessary. And if the choice of location is entirely dependent on personal preferences and peculiarities of the area, lists of materials and tools can be pre -.

Tools:

- Metal shears for profile cutting.

- Screwdriver or drill with low speed.

- Pencil, tape measure, hammer.

- A plumb or building level.

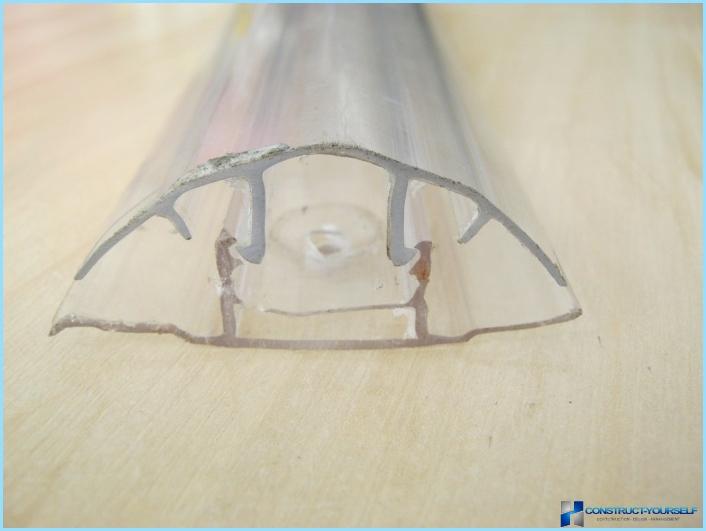

- Mallet or rubber hammer, for fastening of the lock of polycarbonate.

Materials:

- Galvanized profile.

- Roofing screws with rubber washers for mounting of polycarbonate.

- Screws with clamping cap for fixing the profiles to each other.

- Polycarbonate.

- Lock polycarbonate composite.

As you can see, both lists are quite short, and, consequently, the process of assembling the greenhouse is easy. It is important to clearly observe the step by step instructions and not to miss a single step.

The front and back walls of the greenhouse ↑

Let us consider a variant with a gable roof, as a traditional dome design to collect significantly more difficult, especially if in the construction of greenhouses, used galvanized «omega» the profile that is badly bent and will constantly break.

To the design of the greenhouse is smooth, you will need a site with a flat surface. If the rear or front wall will be collected «screw», subsequently, it will be very difficult to straighten, and the polycarbonate will form crooked.

So, spread on the ground a square or rectangle of the profiles, where the bottom and the top is the width of the future greenhouse, and the right and left – height.

Size between the two angles should be identical, or differ by no more than 5 mm. Thus, it turns out that square and not rhombus.

The profiles are inserted into each other and are fastened with screws with clamping heads. As zinc is very soft, it does not need drilling, tapping himself will do themselves the hole and securely fasten the two segments. On each corner put not less than two fixtures, otherwise the design will stagger and break.

Once the square is assembled, find the middle of the upper segment and hold him perpendicular to the line-up. This will mark the roof ridge of the greenhouse. Tape measure measure the size of the angle to the ridges and multiply it by two is the size of the profile that you want to cut and exactly in the middle of the first incision of the walls. Thus, the profile is bent to the desired angle and forms a gable roof.

The roof is attached to the square and get ready to the back wall, that is further strengthened with ribs. They can stand as crosswise, and diagonally. This greatly strengthens the structure and not let it SAG under the weight of snow, and even human.

Similarly, going to the front wall, with the only difference that it is necessary to collect a doorway and the door itself accordingly.

Stiffness and additional skates ↑

When the rear and front wall is ready, you have to slice sections at the height of the greenhouse and bend additional skates. The distance between the stiffness must be accurately measured, as polycarbonate is a standard size, and not to cut along the length of each sheet, it is easier to install fins to the right size.

Standard size polycarbonate – 2.1 meters, but this is too great a distance means, it is necessary to divide by two, and it turns out that the distance between the rigidities should be 1.05 meters. On this basis, calculated the number of necessary profiles and skates. Also cut four pieces of appropriate length of the greenhouse.

Collect frame ↑

At this stage the design of the greenhouse will get curve and unstable, but it is not necessary to pay attention to it in the future it will be strengthened and will vyrovnitsja.

So, you need to install the wall at the desired distance from each other, in the place where it will be placed in the greenhouse. Here, you may need help, someone to hold the wall in a vertical position, but if no one is there, you can simply put temporary spacers.

When walls are exposed, connect them between a horizontal profile at the top of the square. Do the same thing on the other side, and only then fasten the bottom of the screed. Resulting in the finished frame, which is still slack and looks like a greenhouse.

Now make marks on the upper and lower horizontal through 1.05 meters. In these places, put rack galvanized profiles that stiffen and align all the sagging.

When all the ribs are installed, the frame should be put on the level. At this stage, he can still move, but too late to do it will not work.

To the exposed frame of the greenhouse fasten extra skates that should go flush with the mullion profiles. The next stage is mounting the ridge profile. It is necessary to remove the walls in those places where it comes into contact with the corner parts. Thus, a smooth ridge, which is not bulging above the top point.

Additional stiffness ↑

Once all profiles are fixed, we can see that the frame was smooth and almost did not falter, but just to be sure that the greenhouse will withstand all hardships in each aperture between the profiles and extra stiffness on the diagonal from corner to corner. Such fastening is most durable, and the finished design of the greenhouse you can even lean all the weight and it will not bend.

Polycarbonate ↑

The frame is ready, and then you can move to the walls and the roof. First fasten the base of the castle, on each profile, where the junction of the polycarbonate sheet. The castle has a special place for mounting, the tightening screws with rubber washers.

In the grooves of the base of the castle is placed polycarbonate and is attached to the profile by the same screws. How to start a roof or walls, it does not matter how you can do easier and simpler, the main thing that the fasteners were tightened only until to tightly press the sheet to galvanized profile, but at the same time not to break it.

When all the leaves of the greenhouse is fully seated, put the cover of the lock and hammered it with a rubber hammer until it clicks. That’s all, the greenhouse is ready, there to hammer in the ground fixing rebar and you can move on to planting vegetables. In this greenhouse they are not afraid of even the possibility of frost, and too bright the sun will not burn the crop. It is thanks to these qualities, polycarbonate greenhouses made him so popular and all the feedback from the owners of greenhouses are extremely positive.