The process of finishing the walls and ceilings with plaster recently considerably changed. In the recent past, construction workers had to attend to the preparation of the solution. Had to sift the sand, separating the garbage and the stones, to measure the lime plaster. In conclusion, respecting the exact proportions, the constituent elements were mixed and brought to working consistency by adding water. With the advent of ready mixes lion’s share of troubles left behind.

Types of plaster manual application ↑

The construction market is saturated with materials for finishing walls and ceilings. A significant segment is represented by the gypsum plaster manual application. Similar articles, of plaster base with the addition of polymer fillers can create on the walls and ceilings ideal basis and to improve the indoor climate.

Depending on the quality characteristics and value, they are divided into the following categories:

- Relatively cheap formulations contain a small amount of polymers and have good enough grip with the ground. To improve the adhesion of the processed the basis of pre-primed, applying «wet» technology. Repeated coating to provide grip bottom layer is covered with furrows.

- A sufficient content of the polymer increases the cost of the product and allows not to resort to additional techniques and tools to improve connections.

- A mixture containing special fillers, has a higher level of thermal and sound insulation properties.

There is a cement plaster applied by hand. For its characteristics, it resembles a cheap stucco – if you use, it is recommended to Prime the base and to create furrows before re-coating layer.

Rightful place among the many Russian manufacturers is the materials of the brand «VOLMA». The production using its own raw materials and located in several cities. The presence of shopping centers and an established dealer network, allows you to buy a plaster manual application «VOLMA» easily and residents of neighboring countries.

Area of application dry mortars based on gypsum ↑

Depending on the objectives pursued, manufacturers offer a variety of formulations that differ in their technical characteristics. VOLMA manufactures the following products for use in different situations:

- Gypsum plaster VOLMA-Layer is used for manual application, by machine processing should buy VOLMA-Layer-MN.

- A good basis before finishing, will serve as plaster VOLMA-Layer, allowing to continue the process even though paint, even Venetian plaster.

- Different shape depending on the applied technique is able to take plaster VOLMA-decor. This feature allows you to abandon the usual Wallpaper.

- To align the walls and ceilings prior to wallpapering, painting or decoration of ceramic tiles will help gypsum plaster manual application of VOLMA-Canvas. The result of compliance with process is the glossy surface, requiring no additional putty.

Plaster manual application of VOLMA is applied to chipboard, concrete, foam and aerated concrete, brickwork, plaster surface.

A serious competitor to the submitted products are the products of the company «Knauf». The most famous brand of the brand gypsum plaster manual application Rotband. It belongs to the group of finishing materials with versatile properties. The presence of special additives gypsum increases the setting time of the mortar and provides a good grip.

Optimally, its use in the decoration of the walls with concrete or brick base and cement plaster. If necessary, may be used in work on the plastering of polystyrene or cement-bonded particle boards. High quality material provides a coating similar to the plaster of walls and ceilings not only in dry areas, but with high humidity (except for direct ingress of liquid).

The advantages and disadvantages of dry blends ↑

The use of gypsum plaster simplifies the process of finishing the walls or ceiling. The reasons to prefer this kind of material many:

- drying time is much less than cement-sand mortar;

- has the ability to regulate indoor humidity levels;

- has a high level of resistance comparable to concrete;

- gypsum as a main component is an environmentally friendly material does not emit harmful substances and do not cause allergic reactions;

- has ductility and low thermal conductivity;

- provides the ability to single-layer alignment;

- with a sufficient level of whiteness, does not require tinting for further decoration of the walls.

Deficiencies in the plaster manual application of the minimum quantity. Compared with sand-cement mortar it is less durable, and not all options are acceptable to use in wet areas.

Organization of work with the gypsum plaster ↑

Compliance with the manufacturer’s recommendations when working with plaster manual application will allow you to achieve quality results and need no further corrections. Most mixes involve the use of at observance of a temperature mode from +5 to +30 ° Con.

Surface preparation ↑

Preparatory work is organized in the following areas:

- cleaned all the pollution in the form of oil stains, dirt and dust;

- with the base removed detachment;

- the metal surfaces are treated with anti-corrosion treatment;

- absorbent or smooth surfaces, are coated with a special primer;

- the surface must be sound and dry;

After completing all requirements, you can proceed to plaster manual application.

The principle of working with plaster manual application ↑

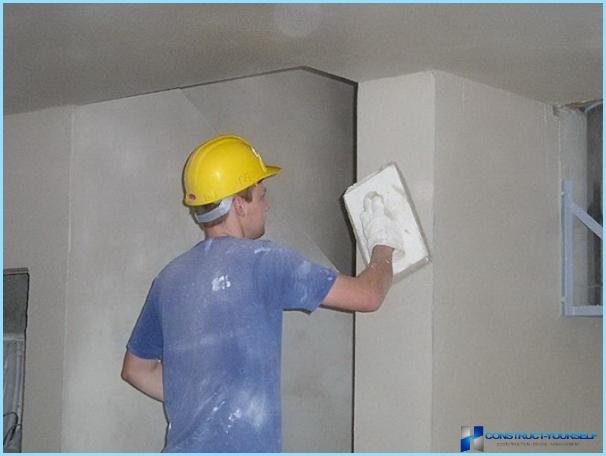

Plaster manual application diluted in clean plastic containers with water at room temperature. A homogeneous mass is achieved by stirring with a mixer or professional mixer. Allowing to steep for 20 minutes, the mixture is applied on the surface of plastering Falcon.

Uniform distribution of the solution can be achieved by using in the beacons. They are fixed to the treated surface by plastering mortar or mounting glue.

To achieve a perfect surface on the outer corners will help the installation of the angle profile.

Spread the plaster manual application of the h-rule. After drying for one hour, to align the surface will help the trapezoidal rule, which will remove the excess and fill depressions.

Using the sponge float, dampened with water, the sprayed solution was triturated to obtain a completely smooth base. When the wall or ceiling will be matte, they wipe out a wide metal spatula. Depending on the ultimate goals, the plaster manual application can be further subjected to polishing or decorating.

The dry composition is stored in bags on wooden pallets. In the room there should be high humidity. In violation of the integrity of the packaging material is poured in undamaged bags and is subject to priority use.

To consolidate the information received will help the following video: