During the construction of baths with their own forces need to consider many factors. Starting from the choice of Foundation, material of walls and roof, ending, at first glance, such things as hydro and paroissiale baths.

Let’s Consider An Example. As a basis we take bath, cut from a bar of 150 mm thick, where the walls are wood paneling:

- in the presence of insulation and vapor barrier in the bath the heat loss per 1 sqm of walls will be 28 W/sq m.

- without the use of heat-insulating materials the heat loss will be equal to 52 W/sq m.

Thus, if you do not apply thermal insulation, additional energy costs for heating bath and maintaining the desired temperature inside the steam room.

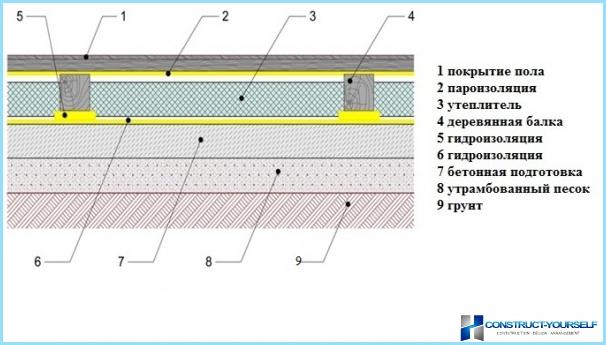

Basement waterproofing ↑

The Foundation is one of the main areas of the vapor barrier. Saturated groundwater, the soil freezes in winter, creating the danger of deformation of the structure, cracking the Foundation. To avoid this, the necessary waterproofing.

Scheme of waterproofing the basement

On a concrete workpiece is placed a layer of waterproofing mastic. The mastic-based high-quality insulating bitumen, which includes a corrosion inhibitor and an antiseptic. Toxic solvents are not available. Used in the small and medium – aggressive soils.

The main characteristics of mastic:

- The absorption of water per day – not more than 0.4% by weight

- The average flow rate at a layer thickness of 0.5 mm – 0.5 l/mTwo

- Drying time of one layer is 24 hours

Use waterproof mastic prolongs the life of the Foundation.

Once the waterproofing is made, it is necessary to insulate «sole» buildings. The most winning option, the use of foam. Paste the sheets of a heat insulator with a width of 5 cm in a checkerboard pattern.

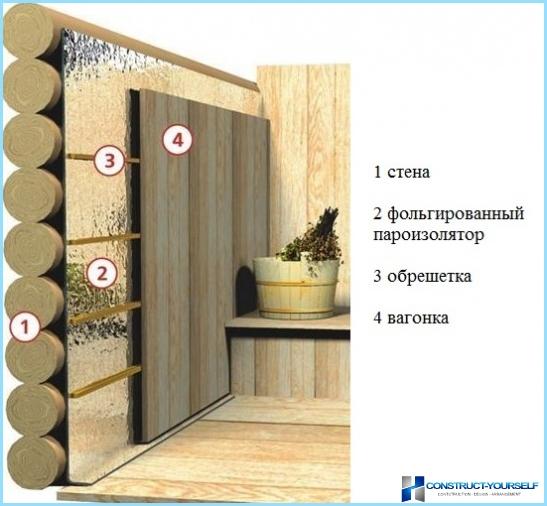

Vapor barrier walls baths ↑

The main task of the steam in the bath is the ability to retain heat. Because in the winter time in the bath guaranteed to be a high temperature inside the room. If there is no vapor barrier, the vapor accumulated in the room, exits through the wall. If the room is not insulated, the steam passing through the wooden paneling, condenseries between the wall and the veneer. As a result, the drops accumulated water, contribute to the processes of decay and mold formation.

Diagram of a vapor barrier baths

Wall insulation from the inner side ↑

For insulation of walls from the inner side between the wooden frame and the wall is placed insulating material. The main thing to choose wisely what kind of vapor barrier material is best for baths.

You can use:

- The foam – is not afraid of moisture, durable, pozharobezopasen. Efficiently isolates any design, even the brick buildings. He is easy to work with, easy to cut with a knife. The most versatile material.

- Plate refractory «Minerit». Plate minerit LV is referred to as the absolutely no combustible materials can withstand the high temperature up to 150 degrees. Have moisture resistance, impact resistance, do not contain harmful and toxic substances. Stove works great in high humidity conditions. Material absorbs and releases water practically without deformation, which makes possible the mounting plates butt.

Insulation materials lay in the space between the uprights, is made of wood or metal profile. The mounting plates comply with the special glue or plastic dowels. If the leaves are more of the opening between the bars, it is a snug fit will provide high-quality insulation of the room. If necessary, the gaps are filled with construction foam.

On top of insulation strips is foil, overlapping of 10-15 cm, the joints are glued with aluminum tape to seal. The foil prevents the escape of heated steam, thereby keeping heat in the room. But due to the high thermal conductivity of the aluminium the heat is on, where is delayed by the insulation. So this design: insulation + foil insulator best option for vapor barrier baths.

But there is a more favorable solution from an economic point of view. Is the application of foil material that combines the insulation and vapor barrier from.

Foil insulation does not absorb and reflect thermal energy and can be used to enhance the effect «thermos». The insulating material does not give cold air to get inside the room and sends warm air to the steam room.

There are many foils, here are some of them:

- Penelon – suitable for protection in zones with high humidity. Is a two-layer polyethylene, one surface of which is covered with aluminum foil. The material is resistant to high temperatures up to 120 degrees, the hydrophobicity of 99%, a low coefficient of water vapor permeability of 0.001 mg/m h PA, low coefficient of thermal conductivity 0.031-0.040 (W/m°C) and low density 26-45 kg/m³. Foil Penelon the thinnest heat insulation materials (thickness 8-10 mm).

- Reflective insulation PenoPremium NPP LF is specifically designed for vapor barrier and insulation of baths and saunas. Manufactured insulation of foamed polypropylene NPP with the subsequent lamination with high-quality aluminum foil. It has high temperature resistance up to 150 degrees, the absorption of moisture takes place in 24 hours – 0,74%. The thermal conductivity is KF – 0,034 W/m*°C. Coefficient of thermal reflection surface is 90%. NPP – ecomaterial technology of sensbilities, freon is not used in the manufacture. When the material is heated an unpleasant smell is absent. Does not cause allergic reactions.

When installing reflective insulation, you must leave an air space between the film and the decoration of the room. To do this, use the crate on top «mirror».

Vapor barrier ceiling baths ↑

Thermal insulation of the ceiling in buncrana important. Hot air is easily lifted up and out. To prevent heat loss, the surface insulated open or closed method.

Open way is for baths without «working» the attic. Wood paneling gidroizolirovat reflecting film, and then covered with insulator. As filling use a layer of sawdust and a layer of dry earth, also used in insulation concrete block, a layer thickness of not less than 25 cm.

When closed way vapor barrier there is the possibility to use the attic as an additional room.«Pie» mounted on a standard scheme: vapour barrier membrane + mineral slab + waterproofing membrane. Then close boards attached to the joists.

The quality of the membrane used hydro-and vapor barrier membranes. The membrane is designed to protect against the penetration of water vapor inside the room and from moisture in the external environment.

Membrane vapor barrier for saunas ↑

Jutafol vapor barrier is a membrane composed of 3-4 layers with micro. The basis of reinforcement mesh made from polyethylene coated with several layers of plastic film. Microscopic perforation present in the film, creates a vapor barrier effect. There are several types of membranes, one species has an additional foil layer. All membrane Jutafol, long service life and manufactured according to the standards and requirements of the vapor barrier. Double sided lamination film much improves its insulation properties. When mounting the film stack so that the aluminium surface was directed into the room. Between the membrane connect the special aluminum tape.

Waterproofing membrane «Megaspan» – applications: protection and insulation of internal elements of the roof from wind, rain. Gidroizolyator promotes the excretion of water vapour from roof space and insulation, helps extend the service life of the heater and overall structure. The membrane is placed on the outside of the insulation under roofing.

Insulation floor ↑

Wooden floors the most common form of decorating the floor. The insulation slabs is possible only for keeps water out of the wooden floor. Laying of heat insulation is performed between the fine and rough floors. Protect the insulation from water vapor barrier on the inner side of the room and a barrier from the ground. As insulation using hard mats of mineral wool or foam.

For example, a waterproofing membrane Megaspan D – two layers of high strength woven polypropylene cloth used as a layer, at the device of floors on concrete bases. In the steam room having concrete floor, are not required arrangement system «warm floor». Enough to place on the perimeter of the wooden lattice. But in the washing room installation of floor insulation will give convenience and comfort to the visitors.