The contents

Home insulation is an integral part of the construction works. Almost every building requires high-quality insulation, because we are in the area with all the climatic zones. Special attention is given to the material for insulation. Today, there are many different heaters, which are used for this purpose. One of the innovative can be called polyurethane foam, which is gaining in popularity. And it’s no wonder, because it differs significantly from other materials. This method is very effective, and with proper execution of the work, you’ll be able to save a lot of money to pay for heating. What is unique about polyurethane foam? How is the insulation of a house with polyurethane foam? What is important to know when working? The answers to these and other questions you will find in our article.

Polyurethane foam – what is it, what its benefits ↑

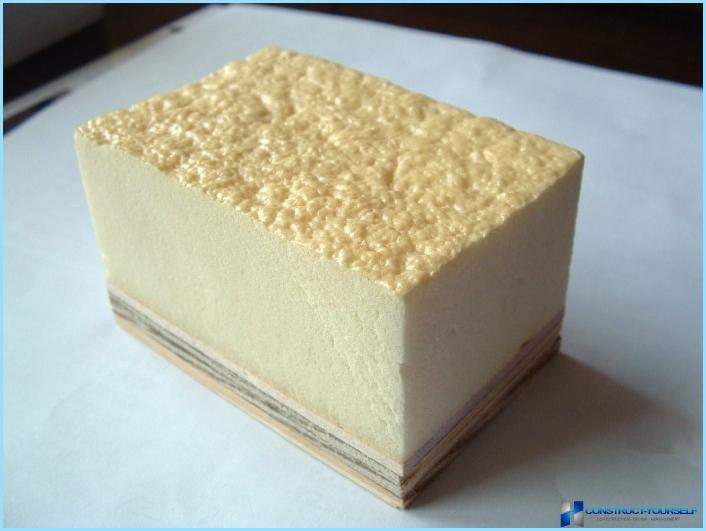

More recently, home insulation has reached a new level. And all thanks to the new developments, thanks to which the light appeared a polyurethane foam (PUF). What is this product? Polyurethane foam is the material, which consists of two polymers in liquid form, namely, of polyisocyanate and polyol. To obtain a polyurethane foam, while thermal insulation works these components are mixed together with a special device. When mixed the air is missing. After spraying on the surface, the polyurethane reacts with carbon dioxide and temperature and begins to foam, increasing in the eyes of more than 120 times.

The advantages of the material very much

- Polyurethane foam has the lowest thermal conductivity.

- Has high adhesion to the surfaces (except polyethylene and Teflon surfaces).

- The insulation has no seams, it is solid. There are no seams, cracks, fasteners, because it is glued to the surface.

- The lifetime of the equipment. If you do not have the insulation to serious mechanical damage, it can last 50 years.

- A low specific gravity.

- Thanks to the microstructure, polyurethane foam resistant to compression and tension.

- Has a high fire safety.

- Don’t need a vapor barrier, as it is sealed.

- Resistant to fungus, insects, rodents and the process of decay.

- Has high soundproofing.

- Environmentally friendly, does not affect humans and the environment.

- A relatively small price.

If we talk about the price, the use of polyurethane foam will cost you much cheaper than foam polystyrene. Still, the ratio price / quality is just perfect. Home insulation polyurethane foam will take a bit of time even if you fulfill it with your own hands. Note that you do not need to buy formula and adhesives for fixing of polyurethane foam.

As you can see, the polyurethane foam is ideal for insulating buildings. Dignity has made it the material of No. 1 among thermal insulation materials.

Insulating polyurethane foam ↑

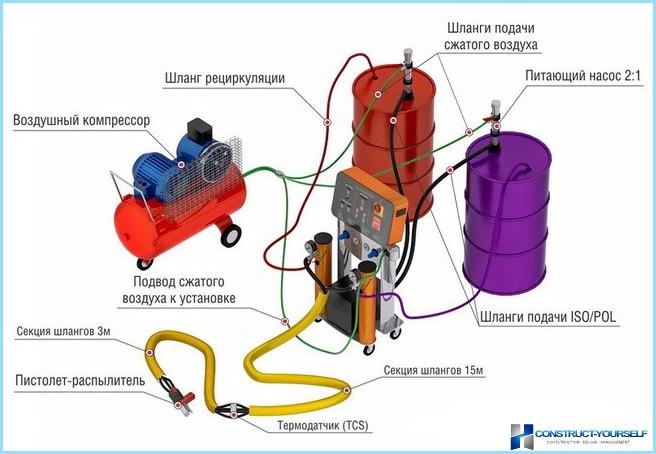

This type of insulation is not quite normal, as the work is to apply (spray) the polyurethane foam on the surface. It is noteworthy that due to the good adhesion, the material sticks to any surface: smooth, three-dimensional or relief. It can be wood, metal, cement, etc. To work you need a unit that will spray polyurethane foam. Without it, nothing happens. On the market there are special installation, which occurs due to the coating. One of these units you can see below. Here specify in detail each element of the design.

The process is as follows: components (poliizotsionat and polyol) are loaded into the tanks. After which the apparatus includes, under the influence of compressed air the contents mixed in a ratio of 1:1 (this is mandatory) and through the hose enters the spray gun. Further, the finished polyurethane foam is applied on dry, prepared surface. Due to the increase in 120 times or more, the material grows before your eyes, fills all the cracks and is solid. After complete drying, the excess material is cut that it was applied decorative layer. This method is called sputtering. But, there is a second method – filling.

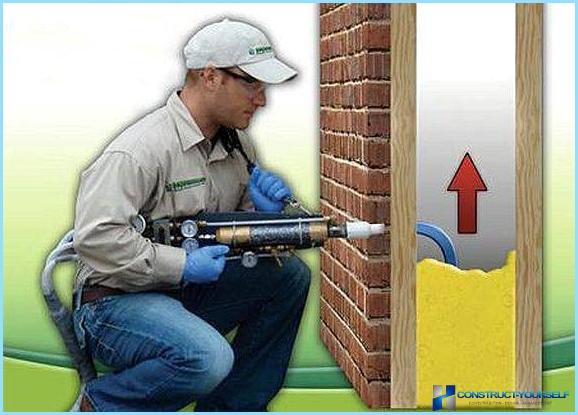

In this case, the material is poured into the prepared space between the wall through the holes. Polyurethane foam fills all the voids, making the wall insulated. Often the fill used for insulation of timber frame house with polyurethane foam. Now, let’s learn how to do all the work yourself.

The choice of equipment and calculation of material consumption ↑

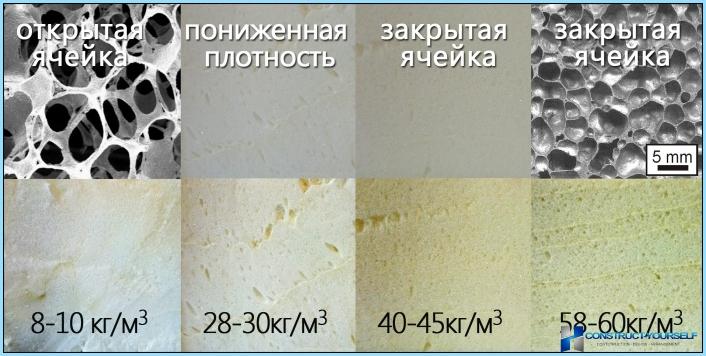

The first thing you need to purchase equipment and supplies. In store buy any brand of rigid polyurethane. But, you need to decide what density to choose. The higher the density, the higher the property of a material not to absorb moisture. Once you have decided on the choice of polyurethane foam, it is necessary to calculate the amount. Note that you need to know in advance which layer of insulation will be applied, as this depends directly on consumption. There are many calculators on the calculation that will be useful. All you need to know: the thickness, surface area and density of the polyurethane foam.

As mentioned above, you’ll need special equipment. In the shop you can purchase a portable unit. Remember that to work with the polyurethane foam it is better to use a high pressure unit. It will be provided uniform and high-quality mixing of the components at the output will form a homogeneous foam. But, not everyone can afford to buy such a device, as its price is quite high. It will be easier to rent or borrow from friends. So you can save a lot of money.

Proceed to the polyurethane foam insulation ↑

When ready, the material and equipment purchased, you can begin to work. We will look at how you can insulate the house by spraying. To insulate the walls of the house can be both outside and inside. It all depends on your desire. Apartment is most often treated from the inside. And not to take precious space, insulation of a private house with polyurethane foam is carried out outside. Let’s look at the whole process step by step.

- For starters, you need to prepare the surface. This preparation includes the cleaning of paint, dust, dirt, plaster and other finishing materials. Doors and Windows be sure to close the film, because you can wash them with polyurethane foam will be very difficult. When the surface is uneven – not a problem, they all disappear PPU.

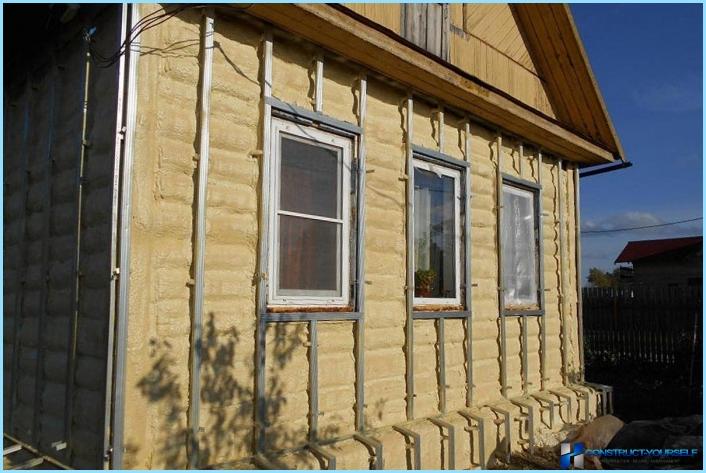

- Now, for all the perimeter needs to do a wooden or metal frame, where will be spray polyurethane foam. The thickness of the blocks or sections depends on the thickness of the layer of polyurethane foam. The framework will serve as a guide so you know what size you need to spray the material. To make the crate carefully, using a plumb line and level, as it will level the wall.

- When the wall is fully prepared, you can begin spraying. The process starts from the extreme cells. Using the spray gun, the material is applied on the inside surface of the wall. There is another point – the intensity of spraying, which you can adjust. The higher the intensity, the greater the layer. The Council! Apply foam only on dry surface.

- The process is bottom-up, movements left and right. If necessary, make several layers until then, until you reach the desired thickness. But do not hurry, after applying the polyurethane foam is expected to increase in volume. Especially well work out the joints and corners.

- When the wall is processed, you can proceed with the rest. We repeat, therefore, difficulties should not arise.

- In the end, is to cut off the protruding beyond the edge of the foam sheathing (when it stood) to prepare the surface for subsequent processing.

The warming is over, you have to do everything nicely, using the decorative materials. It can be paneling, siding, face brick or plaster. Thanks to this modern material, your home will be warm and cozy!