The contents

Modern construction of houses and apartment buildings – the process is incredibly expensive, requiring skills that is called, «dazzle candy out of nothing». There is always the risk of losing quality of construction. Do I need to use in the construction of the house facing brick? This additional cost. In the vast majority of cases the walls are cast from concrete mixes or harvested blocks and veneer decorative material. Oddly enough, but quality masonry bricks significantly improves durability of the main wall, not to mention the insulation and appearance. Greatly increased the value of the object.

What brick are used for walls ↑

For the exterior wall cladding is used:

- Classic ceramic brick lightweight clay;

- Ceramic brick coated sides with icing;

- Heavy hyperpressure and clinker options.

The first option is striking variety of colors, are easy to clutch and relatively inexpensive in price. The strength and quality depend on raw materials and equipment, the most counterfeited famous brand.

The glazed material is very beautiful and the roads. Apply in small amounts and purchase quantities, checking the piece. Masonry, such a brick requires high precision and accuracy.

Heavy bricks hyperpressure or burnt clinker, used for cladding works and for the main walls. Very durable and resistant to ice and moisture. Laying not more complex than other varieties of brick, but higher physical activity.

Methods of laying bricks ↑

To talk about the intricacies of laying bricks is like to teach the owner to ride the bike. Of course, you can learn a lot from the description of the process, but it is better to see how putting a brick facing, can be in the video. The practice of facing masonry is relatively not difficult, but requires precision and eye sizes and distances. Even better, if you have the opportunity to practice to feel and understand how to lay bricks.

Often, when building a house facing work is carried out together with the main block walls. Such a scenario is common in multi-storey construction and / or complicated architectural projects. When a significant thickness of the walls facing brick can be laid in conjunction with the main, but only in the outer layers of masonry.

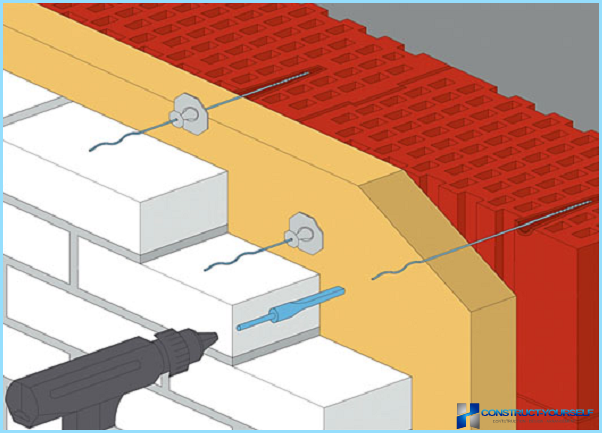

The most common variation is the laying of bricks after the construction of the box house from basic materials – blocks, plates or plain ordinary brick. If no serious errors in the geometry of the walls, the finished frame of the house facilitates the installation of insulation and brickwork cladding material. This option is very popular in low-rise construction in Western Europe. Use the panel Assembly, the main frame one or more two-storey house set on the Foundation very quickly, followed by the beautiful brickwork facing bricks of the photo. Air gap with insulation may be 200-250mm. External wall of facing brick is sealed to the frame with insulation, or just anchor. The result is a durable and warm design.

Often the design of cladding material is performed on the color contrast. For example, dark shades of red to accentuate the walls of the bright brick color ivory, photo.

Preparing ↑

The main scope of works in preparation for construction of the wall will rise on the forest or under already expelled the main wall building materials – bricks and cement mortar. The entire burden of the rise falls on the shoulders of worker. Sometimes to save the masters themselves used to lift the material, but after two or three climbs even the best specialist is not physically able to provide quality and accurate work.

The best material will not give the necessary strength of the wall without cement mortar. To prepare the required amount of binder, use a mixer-a concrete mixer of 50 liters of the mixture, cook it as needed.

To prepare the solution of normal quality use:

- River sand, sieved on a grid and washed at least twice the volume of water;

- Lean clay pre-milled into grits;

- cement PC-400 or 500, with a production of not older than 2 months, but do not use Portland slag cement with a bunch of additives;

- dye, to produce a more pleasant shade.

The mixture was charged successively: a sand – clay – cement into the mixer and stirred. After about 10min of operation pour water and stir the solution until the state of sour cream average fat content. On one part of cement loaded 4 parts sand, and one-tenth of clay.

How to lay bricks ↑

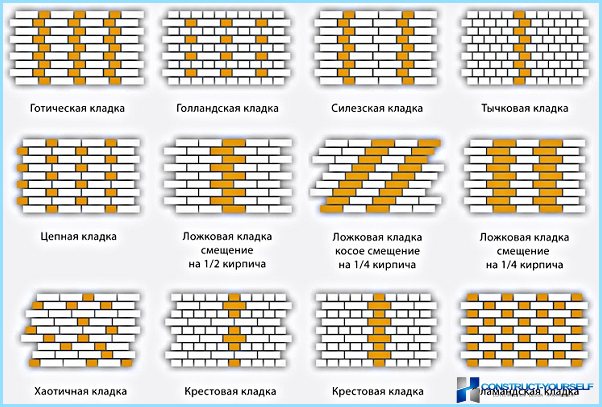

There are several ways, or schemes, binding of bricks. For example, for a two-storey building suitable bonder stretcher bond or option. If the walls need to be strengthened or facing brick needs to strengthen the structure, the masonry can perform in the Gothic pattern. Bonded masonry is the most durable, sometimes stretcher bond brickwork interleaved with rows laid tychkom, getting «Flemish» figure.

The technology of masonry bricks ↑

The key to successful brickwork is the exposure dosage of the applied solution and the geometrically exact formulation of a number of brick walls. The thickness of horizontal and vertical layers of mortar in the joint should not exceed 10 and 12 mm, respectively.

Before laying on the mortar range of the spread in «dry» in view of the gaps to the thickness of vertical joints. Do this in order to correctly choose the location of the bricks in the corner and laying in a row and to at least cut halves. On the one hand, the main must be provided with the beauty and glamor of the figure laying on the other – for maximum strength and minimum work on cutting material. Masonry work on a solution starting with the corners and stretch a row, without interruption, to the next turn or corner.

Cut brick exclusively «grinder», the most powerful of those available for work. Cutting disc for stone good quality and high performance power tools will allow you to easily cope with this task. Unlike ordinary, chop construction hammer lining material is not under load may crack.

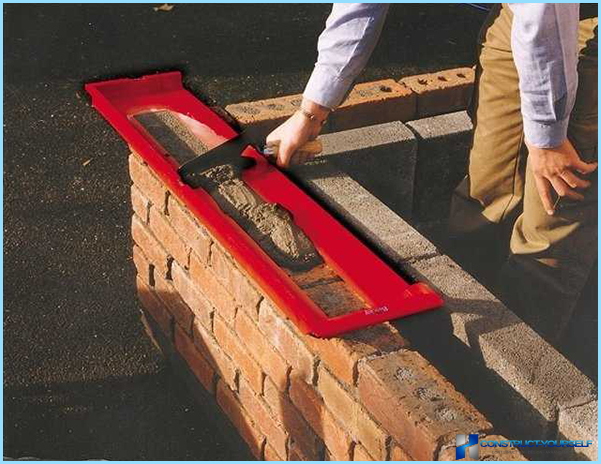

The process of laying veneer identical with ordinary material. A Mason with a professional skills set dosage of the solution easily and precisely lays out the required quantity of binder on the surface of the number. For everyone else, you can use the device for laying bricks, allowing to lay out a precise rate of cement and water «the front» the surface of the veneer. If the solution is made, it can be removed with a stiff brush and damp cloth, do not put this off for «then».

But even experienced craftsmen are constantly used in the construction level, plumb, and horizon, a rope strung along each stacked series. They can withstand the geometry of the walls.

In one approach, carry out a laying 4-5 rows, then evaluate the quality and eliminate flaws. In a row every 70 cm bind the facing masonry to the main wall with rebar or steel wire and dowels.

Often the window openings, cornices, corners, advancement rows are laid with bricks of a different color or texture, the most difficult transition masonry units, usually run poke. Within an hour the seams are treated and smoothed out with a special scraper, which gives a beautiful pattern. To ensure inflow of air between the facing brickwork and the main wall every four or five rows make vent pockets. To do this, lay the grille or leave a few gaps between the bricks.

If there is a threat of rain, fresh clutch, a couple of days be sure to cover with plastic film to prevent elution of the solution. Normal strength brick walls will get in about a month.