The contents

- The advantages of concrete blocks for the bath

- Reviews the use of concrete blocks in the construction of the bath

The construction of the bath is always accompanied by the search for a suitable construction material for walls and foundations. Of course, you can fold the frame of oak timber, but in this case, wooden bath for the price it would cost as a small one-storey house. To build a sauna is not harder than house or garage, but it is important not to miscalculate the materials for the construction. Therefore, to build a better bath from materials which have reliable feedback about their quality and practical application.

From which we can build a sauna ↑

This is the first question that we have to look for the answer in the calculation of the estimates and clarify costs for future bath. Not every material is suitable for the construction of baths, I would not want to spend limited money on is absolutely not good and unsuitable materials.

To build a sauna can be relatively inexpensive if you use affordable materials, which, oddly enough, not so much:

- Wooden extruded plate;

- Red clay bricks;

- Cinder block or expanded clay concrete blocks;

- Foam concrete blocks;

- Wood concrete blocks;

They are cold as ice, and bad along with hot water vapor.

With the exception of the following list can be foam-filled material, but such material has a small flaw, which is to tell a little lower.

Advantages concrete blocks for baths ↑

Few would argue with the fact that the best material for baths is a solid wooden beams, and better whole logs, oak or hardwood. This is true, and the tree for many years will be the most suitable material for frame, and for arranging the inner lining of the room.

Primarily due to low thermal conductivity, good environmental performance and ability to maintain the necessary level of humidity indoors.

If you look at the composition of the given materials, it can be noted that the concrete blocks are the closest in composition and performance closer to the parameters, at least half of the weight of concrete material is wood chips, the volume is approximately 80%.

The advantages of walls made of concrete blocks is obvious:

- Low cost materials and, as consequence, low cost concrete stones. The main components that make up «the backbone» concrete casting, constitute harmless scraps of wood chips, calibrated in appearance, size and shape. This provides a relative «flexibility» and elasticity of concrete casting;

- A good level of insulation, which can be compared only with the foams or mineral fiber plates, while the maximum effect is achieved without hassle with fixing a layer of insulation on the wall.

- Technology of production of concrete bricks uses vibratory loads on the original molding mixture. This allows «squeeze» the volume forms practically all the microbubbles of air quality-concrete block becomes a monolithic mass. The ability of a material «breathe», appreciated, almost identical to the dense woods.

Reviews the use of concrete blocks in the construction of a bathhouse ↑

Often bath in a house built after the fact, of what is left of the main building, and at best on the margins, free from major built-up location. To reduce losses there is a sense to make itself a bath in an addition or build a detached building, which has its own oven with heater, as a rule, wood or fuel briquettes.

All practical experience in the construction and use of the baths of wood-concrete bricks can be reduced to a few simple, proven allegations. First, the cost of required quantity of cement wood for the construction of baths cost at least 40% cheaper if blocks to take a piss with his hands, not ready to buy.

Second, the material has unique mechanical properties that allow it to cut and cut stones of any size and configuration. At small weight of the stone paving speed of about twice without loss of quality.

Third, almost everyone who had originally planned an additional external insulation brick walls baths from concrete block, abandoned the original idea. Instead of insulation, the outer surface of the concrete stone sewed up the lining or siding with a small air gap between the wall and the cladding. The outer surface of the wall of the concrete material sheathed wood Board, and all the bath was ready. You can hear a lot of reviews about the complexities of thermal insulation of walls baths, combating condensation and excessive fuel consumption for heating steam, was built of brick and lined with base boards. Walls baths from arbolita decided the vast majority of problems in one fell swoop.

Further – more. Some enthusiasts managed to put on concrete pad bath, the insulating layer of the thin sliced arbolita. A similar insulation from cut layers of wood concrete stone laid on the overlap of the ceiling baths.

Result – fuel consumption for heating of the bath was reduced at 12-15%. However, such masonry wood concrete stone is produced with extremely high content of wood filler in 90% of the volume. The filler block was cut long shavings of processed lime and pine were cut on the lathe at five-centimeter thin crop, the size of a matchstick.

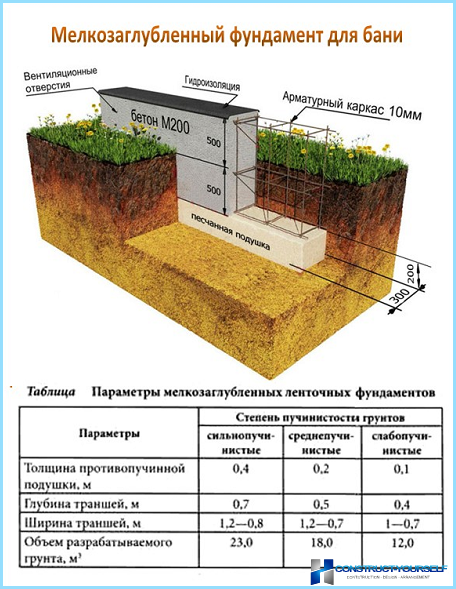

In addition, for similar concrete insulation of the ceiling or the Foundation had additionally comply with waterproofing of polyethylene film and make ventilation ducts connected to the vent pipe. In this design of any drip condensate is removed from the ceiling and profundamente space-concrete walls for hours.

How to replace concrete block in the construction of a bathhouse ↑

Among the above materials, there are many worthy competitors wood concrete stone. They often show the best characteristics in specific areas and properties.

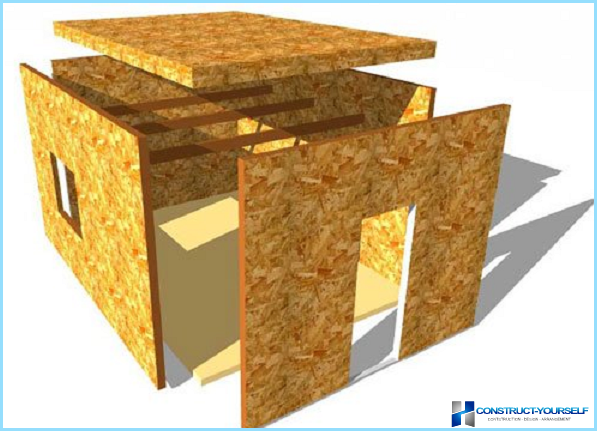

Blocks of pressed wood chip mass ↑

Materials of the molded chips on the basic properties virtually identical light breeds of wood construction, but with one caveat. Unlike concrete blocks, many of them used a variety of resins and polymeric materials. The organic binder is not always well withstand the conditions of temperature gradients of baths, and those brands that are positioned as a complete replacement of wood as expensive as the wood itself. To build a sauna you can, but the cost of the design will be 60-70% more expensive option of concrete block.

On the market there are a lot of interesting offers modern composite materials based on waste wood processing industry and natural solutions of salts and alkalis. Unlike concrete block, the material resembles heavy mineralized wood, but the price and ability to conduct heat correspond to the characteristics of hollow ceramic bricks.

Foam concrete, brick and cinder block inferior wood concrete block in the construction of baths. The last two are the most common building material in construction, very durable and resistant to frost and fire. But in the construction of the bath they can’t give those qualities-concrete block – high water vapor permeability, low cost and excellent thermal insulation. Need additional wall insulation, increasing the thickness of the masonry up to 25-30 cm, corresponding to the width of the masonry-concrete block. Win there, only increases the estimates.

To cinder block, there is another factor – low environmental friendliness. If concrete block deliberately does not use toxic or radioactive substances, the blocks filled with slag from the combustion of coal can often contain radioactive cesium and strontium. Especially in materials for the handicraft industry. Therefore, these units are not recommended for the construction of baths.

Blocks of gas-filled foam can be called material for the Northern latitudes. Its production is cost-effective in the absence of wood, blocks of foam are easier to tolerate severe frosts than the blocks-concrete structure. But in a steam bath, or blocks of foam are more sensitive to diffusion of water from the surface deeper into the material than sand-lime brick or concrete block. Temperature changes in a wet environment of the bath will be a sentence of foam. Need waterproofing or plaster, which partially offsets part of the advantages.

The disadvantages of using concrete blocks for baths ↑

Concrete block is not a perfect material, hardwood timber solid wood is considered more suitable for the construction of baths. But even in this case, a box from wood needs in the outer wall – durable and lightweight frame baths.

If used for the walls of the bath-concrete blocks, it is worth considering some specific features of the material:

- Wood concrete block in the construction of the bath must be protected against constant moisture and complete the insulation, especially in the Foundation and places of runoff and water harvesting;

- Blocks of mass concrete do not burn, but are not safe. Under the influence of high temperature wood filler will decompose to release carbon monoxide and water vapor. The force of the internal pressure is capable of chipping whole chunks of blocks, but what is more dangerous, can fire lead to poisoning by the decomposition products.

The quality of a bath of concrete block varies greatly depending on how matured manufacturing technology. With careless attitude to the proportions or the quality of the material design of the bath will collapse under its own weight to the end of the building.

Conclusion whether or not to build a sauna from concrete block ↑

Concrete block can be easily purchased in small quantities and on their own experience to test its mechanical properties. And only breaking into a dozen blocks, it is possible to make a conclusion about its suitability. And even better to find at least one construction of the bath or summer kitchen, built of arbolita, and to ensure the quality of construction material.