The contents

Fire — available source of heat used everywhere. However, the fire in buildings is associated with some problems. Even if you create the right conditions and prevent it from spreading, it is necessary to organize the permanent removal of smoke and appropriate traction. To do this, and used chimneys.

The purpose and features of the chimney ↑

The chimney is a practical and simple tool that allows you to divert all the smoke. It is used for both open and closed sources of fire. Konstruiruet in the form of a pipe or mines, the chimney provides good ventilation, pulling the smoke from the fire. Although this slightly reduces efficiency of heating, this approach ensures clean air in a heated room.

However, the design of the chimney is not so simple. She must meet all requirements and standards, including:

- The constant exhaust air

- Adequate patency of the way

- The minimum number of horizontal sections of the path

- Condensation

- Resistance to extremely high temperatures

And other features that should be considered when installing such structures. This will ensure its optimal technical characteristics and protect from possible problems during heating of the furnace or fireplace.

Optimum design of the flue assumes a cylindrical shape. This will prevent you from unnecessary problems with the aerodynamics, but also reduce the rate of accumulation of soot on the inner walls.

Peculiarities of various types of chimney are also different. For solid fuel boilers often use common pipe, which is sufficient to isolate and correct output. However, if you create a chimney for a fireplace or a stove, you must thoroughly calculate design providing good traction and other details. It’s important points, providing the full functionality of this element furnaces.

The choice of design ↑

Design may vary depending on the type and characteristics. Now note three kinds of such products, which can be distinguished by the materials used:

- brick

- steel

- ceramic

Their significant differences, and the setup is radically different. Also the design can change based on layout, place the pipe and its additional features.

During the planning and selection of materials should consider the following points:

- The temperature of the smoke and the radiant heat

- The presence of condensate

- The rate of accumulation of soot and the possibility of its cleaning

- Aggressive influence on the structure

- The optimal choice of output tubes

And other nuances. This will ensure high efficiency of the boiler or furnace, and reduce the risk of spread of fire or destruction of the output tube. The best choice is always the brick option, because it retains heat, withstands high temperatures, is poorly susceptible to condensation and is resistant to various fuels. Although the construction of such structures is their complexity, long-term and reliable option.

With regard to ceramic options, they are best used for gas and oil boilers. Ceramic is neutral to aggressive substances, and the outside temperature is very high. While ceramics are resistant to corrosion, durable and strong. However, its installation must be done professionally, because it is a very fragile material.

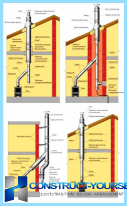

The least popular option is a chimney made of steel. It is suitable for those areas where it is difficult to organize a full-fledged masonry for smoke extraction. The cost of this option is low, weight is moderate, and the installation is fairly simple. However, steel is necessary to provide additional insulation or double circuit, to reduce the risk of ignition of surrounding materials.

The chimneys in the homes often have a complex structure, which can be seen in the figure. Here are the items for air intake, an insulating part for transition between floors, brackets for fixing and a lot more. All this is taken into account, because the reliability of the chimney reduces its danger to the building.

Flue selection and determination of design — important points that should determine prior to installation. Each material has its own characteristics in the construction, define technical performance and reliability of the design. Ignoring this will lead to risk of ignition or low efficiency in the operation of the chimney.

The chimney of the brick ↑

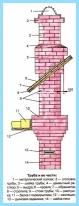

Brick version of this design is the most common and optimal in many buildings. It is simple to build, but it is necessary to consider some details of the design. It’s not just a straight brick chimney, and diagram of several components of the elements. Among them:

- The neck of the furnace

- Flue gate valve

- The fuzz

- Otter

- The top of the tube

The first two elements connect the furnace with a pipe allows you to adjust the thrust of the air coming out. Next, a few rows comes the fuzz — the extension that you want to protect the walls from overheating. Often installed in front of interfloor overlapping.

Next comes otter, protecting the building from atmospheric precipitation is able to fall through the cracks near the base of the pipe. After the design is completed with the end where you install the cap. It fixed the cap or other elements that protect the chimney from rain and wind.

Design is more clearly shown. This takes into account the nuances of the construction of the chimney, and the location of all its elements. Although some may seem superfluous elements like otters or raspushki, it is a proven design providing the greatest efficiency and durability of the elements. The advantage of brick is that they are difficult to add into a ceramic or steel chimney.

The construction consists of the following steps:

- Preparation of drawings

- Prepare the Foundation

- Phased masonry chimney

- The conclusion to the roof, installation of a cap

- Insulation design

The first stage is to prepare accurate drawings for the further construction of the structure. It is necessary to consider the exact height, approximate thickness of the weld, to calculate the weight and location of composite structural elements.

Next, you need to prepare the Foundation. It needs to withstand the weight of the chimney brickwork. It is necessary to Supplement its steel rebar for better stability.

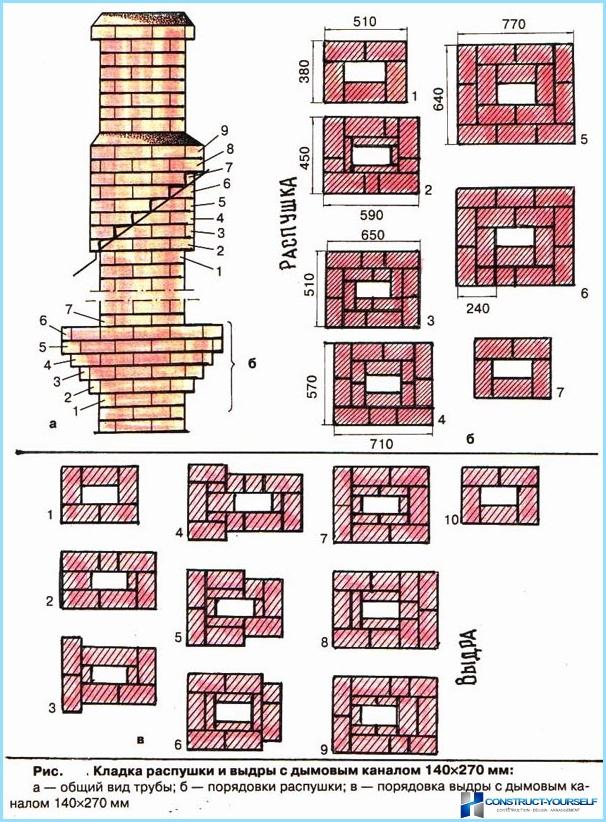

After these steps immediately begins masonry chimney. It is the creation of the base, connecting the pipeline and where it is to divorce the fire, as well as further construction of all components of the design. If the masonry is relatively simple, it is necessary to consider features raspushki and otters. Their creation can be seen in the following image:

Next, you create the conclusion on the roof where you are installing the well head and cap. In the future, all seams sealed, as the weak part of the structure. Insulation required in weak areas where a fire can significantly heat the brick, which will cause damage or condensation.

These are the basic steps that should be considered when building a masonry chimney. Although the design and simple, do not neglect the help of professionals. For a large building to the right conclusion of a flue, creation of Foundation and the intersection of the partitions between the rooms — are important steps determining the efficiency of the chimney.

The chimney in the bath ^ the

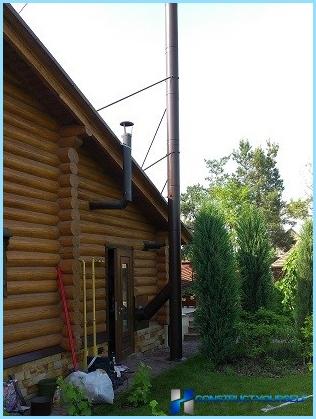

For bath the best option is a metal chimney. Stove rarely reaches extremely high temperatures, and the atmosphere in the bath is only a good insulation of the room. But it is better to take stainless steel, because the humidity in the building will be high, which significantly affect the durability of the metal.

The options presented show the available insights of the chimney of the bathhouse. It is worth considering that they all have insulation on the external site. It is necessary to reduce heat loss and less damage to the metal.

The design of the chimney for stoves is not difficult, it is necessary to consider only important thing — condensation. He will continue to accumulate because of the high temperatures and humidity. This is undesirable because reduces the length of the chimney.

Then begins the Assembly. Although several different designs, the Assembly is approximately the same. It consists of several components:

- Single-loop pipe connecting the furnace and chimney.

- Adapter.

- Dual pipe.

- A steam trap set.

- Umbrella.

Initially, it is necessary to assemble these components. It is held by clamps and adapters, allowing to connect various components of the chimney. Also need drainage under 45 degrees, allowing you to bring the pipe to the side. It is advisable to it is not through the roof, and a wall that will protect the structure from condensate.

Next, you need to carefully insulate all the passages. Insulation of the pipe itself, if it is dual, not required.

A chimney for solid fuel boilers ↑

The flue for the boiler is slightly different from other variants. It does not require such hard isolation, but needs reliable chimney capable of withstanding exposure to elevated temperatures. Quite often the heat from these boilers are able to burn the thin steel that often used for budget chimney.

The construction of this chimney is similar to the options for the bath. You must create the connection with the boiler, and then bring it through the wall to the outside. It should be noted that the smoke from these boilers is often abundant, so you should take care good traction.

During the construction should consider the following points:

- The thickness of the material used

- Thermal insulation of the chimney

- Good traction

- Simple cleaning of the pipe

On the basis of this will come robust design able to fully eliminate all the smoke from the boiler, without creating the risk of fire in the building.

For a better understanding of the design of the chimney should watch this video. Here described the process of Assembly of such structures for heating and cooking oven: