The contents

- The principle of mixing flows of different temperatures

- System with hydraulic decoupling of heat carriers

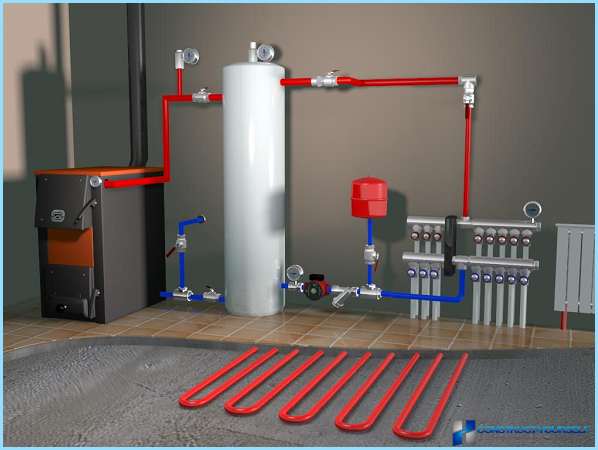

In most modern heating systems lies the original defect that prevent the effective organization of heating with the boiler of periodic action. The problem lies not in the principle of fuel combustion, although there is also not going smoothly, and in the organization of heat transfer from the heat source of the combustion front in solid fuel into the air space of the dwelling rooms of a house or apartment. Heat accumulators are designed to compensate for the loss caused by the periodic operation of the boiler. To be precise, the storage tank is needed for every boiler of periodic action.

Device, proudly referred to as the storage tank for the boiler, is a tank of considerable capacity, reaching in some cases up to 10 tons of water, with a system of heat exchangers. That should give the use of heat storage:

- Safe accumulation of excess heat generated by the boiler into a water flow of coolant;

- To increase the duration of the cycle heating – cooling of the boiler plant, thus simplifying maintenance, release from having to run it at night or at an inconvenient time for yourself;

- To increase work efficiency and prolong boiler.

In addition to solid fuel boiler, the need to use heat storage have systems to electric boiler. In this case, the use of storage tank is dictated by artificial selection in favor of periodic heating, and only in night time period when there is a possibility to use more favourable preferential tariff.

The design of modern boilers in favor of the manufacturer with the most optimized from the point of view of cost and manufacturing cost. The modern boiler is made of sheet steel with a minimum of scarce and expensive copper and Nickel, and a stove «stoves».

In his device there is no hint of the heat accumulator. This boiler is in principle not able to accumulate thermal energy. Compare modern pellet or coal boiler with the old heavy designs of heating boilers of cast iron, and even better, with the device of the usual rustic stone oven. In the latter case, the function of the accumulator efficiently performs masonry, directly absorbing heat from the flame and evenly transmitting in the air in for 10-12hours.

Therefore, modern Central heating boiler is inefficient without heat storage. Solid unit will be indispensable in work and will do without multi-ton tank, if it’ll get the automatic loading system of fuel into the furnace and the subsequent purification from ash.

How it works the storage tank ↑

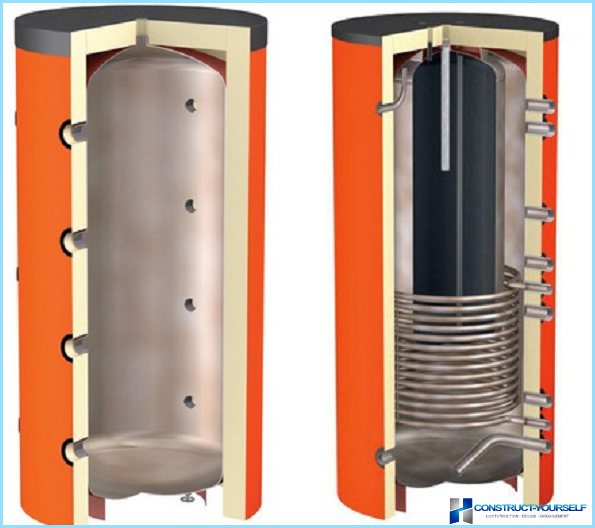

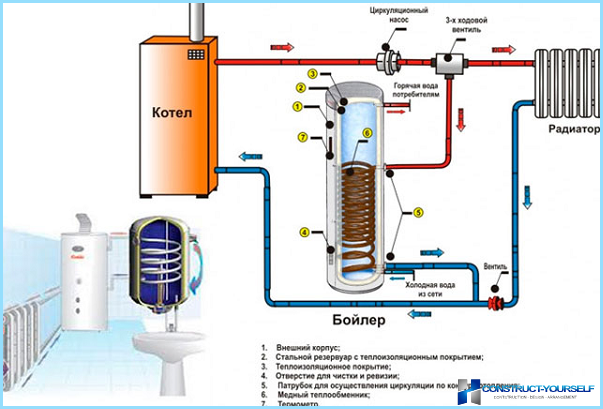

The purpose of the heat accumulator – provide additional thermal energy to the circuit water heating after the reduction or cessation of generation of heat of the heating boiler. For this huge capacity is a large amount of boiling water at a pressure of about 3 ATM. In the body of the tank are soldered to the heat exchanger, through which is «the fix» heat in the battery and reverse the selection in the heating system. Often the tank additional heat exchanger with the purpose of obtaining hot water for the needs of kitchen and bathroom.

The principle of mixing flows of different temperatures ↑

For quick warming of the room the storage tank via the three-way valve off from the chain of the movement of heated coolant. Only after heating of the flow of water in pipes over 60onSince the contour connects the water from the storage heat storage. And, while working, the boiler heat goes in two directions: in the drive and to the radiators heating.

In a similar principle, there are certain positive aspects:

- Quick warm-up of the dwelling, and only then is the discharge of excess heat in a heat accumulator;

- Mixing principle ensures efficient heat transfer;

- The supply of water in the storage tank is a strategic reserve for the boiler, thus preventing possible burn-in violation of the water circulation in the heating plant.

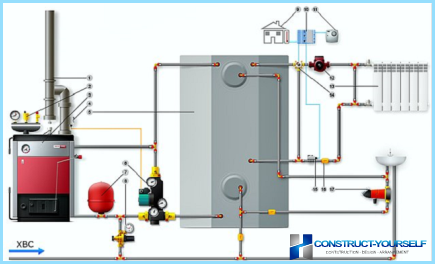

Ideally, the water circulating in the hot heat exchanger of the boiler should not be mixed with the coolant flowing across the heating system. So often in the heat accumulators use a different scheme – with hydraulic isolation and separation.

System with hydraulic decoupling of heat carriers ↑

In this scheme, the storage tank plays the role of one of the elements of the heating circuit, it is impossible to exclude from the stream. In fact, the storage tank, there is a constant transfer of heat from selected «hot» the contour of the boiler and the rest of the mass of water or coolant circulating in the heating system.

What it does:

- High-loaded heat exchanger of the heating boiler requires the use of special, purified from impurities and oxygen of water. Only such water ensures long life of the tubes and gaskets of the heat exchanger. Supply of necessary amount of treated water is stored in the additional boiler.

- Through a special design of the heated water from the tank of storage tank, it is possible to easily adjust the temperature of the selected fluid, which simplifies the control system of heating.

The disadvantages include the need for additional devices – two pumps: the circulation of the coolant and system security of power supply. Sometimes redundancy is used to pair devices – voltage Converter and an electric accumulator for the heating boiler. Otherwise, a power outage can lead to a serious accident in the primary circuit.

More challenging and advanced scheme involves the use of two separate heat exchangers are combined in one housing the accumulator tank. This is a more rational way of organizing the work of the heat accumulator with a high degree of redundancy. It can be recommended for those wishing to make a storage tank for the heating boiler with their hands.

Construction of storage tank with its own forces ↑

For the manufacture of a heat accumulator should be to determine the heat capacity of the battery. There is a certain method of construction of the storage system. The amount of water in the battery take, on the basis of 30-40L of fluid for every 1000W heat output. In this case, the house 100mTwo heated area will require a capacity of 350-400литров. The best option would be to use ready bolinaga tank with water level sensors, pressure and temperature.

If the workload is selected, the system with mixing, properly functioning even in the absence of special pumps in the heating circuit have to install the three-way block-tap.

More simple schemes will require to be mounted in the tank one or two of the heat exchanger ↑

It is better to use a heat exchanger of the same material as the container. This ensures standard quality of the weld when installing the heat exchanger. In addition, in the cavity of the heat accumulator it is better to apply magnesium anode protection electrodes, similar to electric boilers hot water. The outer wall of the tank – accumulator sheathe insulating mats or mineral wool.

Promising options storage tank ↑

One of the interesting solutions are small batteries that use water instead of low-melting paraffins or silicone oils. Due to the much higher heat capacity has the opportunity to use a safe small accumulation systems for electric boilers heating systems of apartments. Instead 300литровой heavy capacity implies the use of two-piece battery a total volume of 50L of coolant having a thermal margin in 15кВтч.