The contents

Foam blocks: concept and General characteristics ↑

Suburban construction has always been popular at all times. Consumers, tired of the bustle of busy cities, rush to nature. Currently, many of them reside outside the city, getting to work on the car. Therefore, the issue of building quality housing relevant. Many years in the construction of a country house reigned a tree structure which is rugged and durable and beautiful in appearance. Gradually the area of interests of builders and their clients has expanded, and they began to pay attention to other materials. Some of them not inferior to the tree. One of such materials include foam blocks. As a type of cellular concrete, the foam blocks can guarantee its owner a long service life. House of foam blocks are not exposed to harmful environmental influences, and their partition walls accumulate the heat in the room. This reduces costs for electricity and heating. In addition, the foam block is not terrible temperature changes, in the house formed a healthy microclimate, similar to the housing of wood.

Additional characteristics of the foam blocks ↑

Foam blocks and unlike brick, are large. This allows you to build partition walls made of this material in a short time. In addition, promptly work builders helps lightweight foam blocks. They quite easily drilled various holes, for example, to conduct communications or water pipes, and electrical wiring. The sizes of the blocks are strictly fixed and can’t have differences of more than one millimeter. It is important that the blocks are not toxic, they do not release into the atmosphere of harmful substances. All these qualities lead to the fact that the construction of houses of foam blocks acquired a large scale.

Partition blocks ↑

Partition blocks are not used in the construction of walls and their insulation. They are intended for installation of internal partitions in buildings of various purpose, but with a maximum height of 3.3 meters. The division of space is most often with the help of partition blocks. They have optimal performance in the following characteristics:

- sound insulation;

- insulation;

- high load capacity;

- low weight;

- low density;

- finishing capabilities.

Now let’s see how to build a house out of foam blocks with their hands.

What is the project of the future house? ↑

Projects of country houses of foam blocks is a key document that reflected the architectural and building requirements for the future structure. You should not start building a house without a project. The consequences can be undesirable for the owner: he will not be able to place the house in the property. Therefore, the two-storey project houses of foam blocks are obligatory acts. Finished projects consist of two parts:

- Architecture and construction.

- Engineering.

The first part includes drawings that specify the geometric parameters of the building and its structures.

The second part is the engineering documentation is divided into three sections:

- water supply and drainage;

- heating and ventilation;

- electrician.

The stages of construction of houses of foam blocks ↑

- The markup of the trench under the Foundation. To build a house out of foam blocks, which meet all quality standards, it is necessary to conduct geophysical exploration of the area, which is planned the construction of the house. This is necessary in order to avoid unnecessary problems with subsidence and with the subsequent operation of the building. Keep in mind the requirements of normative documents: the distance from the boundaries of the land to the housing being built should be at least three meters, and farm outbuildings – one meter.

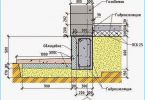

- Pouring the Foundation. First mounted formwork. It can be made from timber, and is better to use softwood. It is spruce and pine, larch. It is known that wood has the quality of reliability and durability. It is necessary to observe the proportions of the boards: thickness – 19 mm and a width of 150 mm (maximum). For the interior trim is still used roofing material, as well as fittings for frames. For monolithic foundations and fittings shall have a diameter of 32 mm. All necessary formwork materials you can buy ready.

- Pouring the Foundation concrete – a very important moment, the amount of concrete necessary to accurately calculate. It is better to carry out the work in one step. Some specialists do this in two stages, the result is cracking and subsidence of the Foundation. The concrete hardens for about a month. Finished ground to cover in order for it not to feel precipitation.

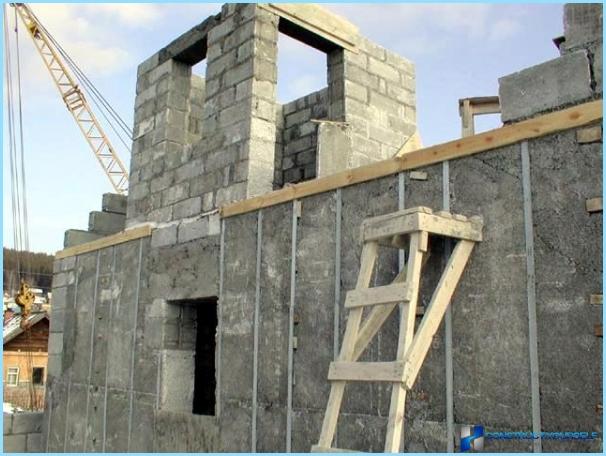

- Wall ceiling. After is waterproofing the Foundation and laying of communications, start laying blocks. Before this step is necessary to calculate the exact amount of material used. Very important is to put the first layer of blocks. At the same time to monitor the thickness of the seams, because according to the standards it should not be above 10 mm. It is necessary to maintain the insulating properties of the home. And this, despite the fact that the foam block as the material has a good performance of thermal insulation! Too wide joints can hurt even him. Usually with masonry walls using such a working tool as a level. Solution and adhesive composition is applied first on a horizontal surface. After that, the vertical.

- Exterior and interior installation. After performing the above manipulations usually begin the roofing and interior decoration. Walls between the rooms also are made of aerated concrete blocks. Outside facing the house is a must, as the foam is absorbent. Facade cladding is made of various materials, their choice is wide. As such, it is possible to offer:

- brick (facing);

- siding (vinyl or metal);

- lining;

- plaster.

Facade insulation is not required for houses of foam blocks, what is their added advantage.

Options Foundation ↑

The Foundation for the house from foam concrete block and its precise choice is important for further exploitation of the building. You can build a one-storey house of foam blocks or to attach the second tier – heavy base will still be extra. The most suitable grounds for homes of the examined material are the following types of foundations:

- tape;

- columnar;

- slab.

Each of the offered bases is used, depending on certain factors:

- the composition of the soil;

- the degree of heaving of the ground;

- groundwater level.

In the preparation of projects of cottages from foam blocks specifies the type of the Foundation. In that case, if groundwater is located at depths greater than three meters, the ground under the house can be tape low-depth. Its main characteristic is that the depth of the trenches is in the indicators no more than 50 centimeters. They are easy to dig yourself. Using the shovel or mini excavator.

House of foam blocks: which roof to choose? ↑

Roof for any building needs to be reliable and durable as well as aesthetic. As for the houses of foam blocks, it is best to use the roof has a small weight. Therefore, we can offer several types of roof: pitched or flat roof. It is considered that the pitched roof is ideal for a small cottage of the foam blocks because there is a possibility of the extension of a roof beyond the load-bearing walls. This leads to the fact that the walls are wet from rain. Many owners who built the house from foam blocks, using a flat roof, though experts advise not to do this. The main advantage of a flat roof, you can consider it a small cost for its creation does not need sheathing and rafters. But during rain the walls of the house with such a roof will always be wet. And the house of foam blocks it is not recommended to moisturize: it is detrimental to its performance properties. Therefore, the ideal roof for country houses of foam blocks is pitched roof.