The contents

For residential buildings have high quality insulation that will not be afraid of the cold even in severe winter. Thus the need to insulate not only the walls but the Foundation. However, some material is better suited for this task? Although a lot of options, in this respect, by far the leading polyurethane foam.

What is polyurethane foam ↑

Polyurethane foam is increasingly used for thermal insulation of buildings. This is a practical material that combines many of the benefits. However, what he did stands out among other options?

His characteristic difference — coating method. Polyurethane foam is created directly during the warming, initially consisting of two components. They are liquids that when mixed form a mixture, which starts foaming and increase rapidly in size. Literally one minute she is fully cured and become foam structure with high thermal insulation.

This allows you to create a monolithic layer with no joints, the method of application does not require installation or laying of polyurethane foam. Need only spray it on the surface, and then he will form a necessary protection against heat leaks. While spraying it on any surface regardless of their form and features.

It should be noted that the polyurethane foam is distributed into two views. The first one has closed cells, the second open. The private option is much more priority, because more resistant to moisture and has a denser structure. And the insulation of the Foundation this is especially important, because the polyurethane foam is applied on the outer side, resulting in contact with the environment.

Advantages of polyurethane foam for insulation of Foundation ↑

Polyurethane foam has several advantages that make it an ideal option for insulating a Foundation. First, it is worth noting a feature of the application. It is a variant of the insulation does not have any joints or cracks through which moisture can enter the building. None of the material can not achieve such a result without additional waterproofing layers.

Also polyurethane has the following advantages:

- Resistance to moisture, temperature changes, plants and insects.

- Low rate of heat conduction.

- A structure that is moisture.

- Snug fit to the building, which prevents the occurrence of condensation.

- High speed application.

- Low cost material.

Polyurethane foam has many other features that only distinguish it from other heaters. It comes in cylinders, which can significantly reduce transportation costs. And its application can be carried out even by beginners, if you carefully observe the regulations and to consider recommendations.

Again, the service life of such material decades. So you should not worry about safety of your Foundation, and also reduce the cost of heating the building. After all, the Foundation of the house and basement are a common cause of cold in the building even in cases where Windows and walls are already insulated.

So this option is ideal for insulating the basement. Polyurethane foam can significantly reduce heat loss and increase the life of the base of the building. To apply it you can own, which will be discussed further.

Preparatory work before applying ↑

Before applying polyurethane you need to do some preparatory work. They significantly increase the efficiency of the insulation and extend its service life.

You first need to determine in advance the scope of work, which will go to the insulation. It is worth remembering that insulation is not only aboveground parts but also depth. On average, take approximately 1 meter underground part of the Foundation and about 50 centimeters from the top.

Next, you need to make a trench around the building so, to free up work space. Deep she has to go 1 meter, a width of about 70 inches. The second indicator is individual, it is necessary to release a place to work.

Next, you need to do the following set works:

- Clean the surface of the base from dirt and plants.

- To remove or restore shaky and crumbling part of the Foundation.

- Dry working surface.

First you need to remove all the dirt, fungus and plants that exist on the working surface. Then you need to check the Foundation example of cracks, splits and crumbling parts. Although the polyurethane foam can be sprayed onto any surface, its uniformity and reliability increase the use life of the material.

Further, it is necessary carefully to dry the Foundation. It’s enough to leave it for 2-3 days, provided the sun is shining and no precipitation. Otherwise, you need to use special equipment.

In the above-ground part of the Foundation that you want to insulate, you should make a frame for the cladding. To apply facing materials to the polyurethane foam will not work, it is dense enough. Therefore, the required metal lath, which is further mounted panel.

Substantially all irregularities are leveled. Sometimes it makes sense to conduct a full restoration of the basics before starting work. This will improve the effectiveness of insulation and increase the duration of its use.

After preparing the workspace, you must cover the Foundation of the protective structure. This allows you to remove various micro-organisms, to enhance adhesion, and increase its service life. Next you need to cover it with bitumen in 2 layers. Although the polyurethane foam is sufficient protection against moisture, an extra layer of protection in the form of bitumen will not prevent.

Application of polyurethane foam on the Foundation ^ the

After completion of all preparatory work for starting the process of applying the polyurethane foam. This requires a special tool, namely a spray gun. In addition you will need:

- Old or working clothes;

- Respirators;

- Protective eyewear;

- The components of the polyurethane foam.

Since the material is highly corrosive that regular clothes cannot be used. In addition, getting into the respiratory tract or the eyes can significantly harm your health.

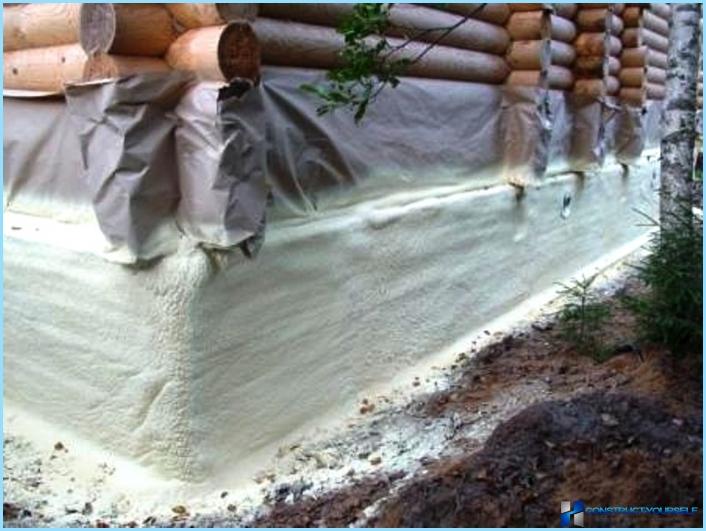

Next, you need to connect the cylinders with the components to the gun-spray gun, then you can begin work. Gradually spray the contents on the Foundation from the top down, walking around the perimeter. One approach is to apply no more than 5 inches of insulation in thickness. If you need more thickness, you can do several approaches.

It is important to note that the polyurethane foam is sprayed on small above-ground part of the Foundation, the amount of which shall not be less than 50 centimeters. This is to prevent flowing of the sewage over the insulation layer, which would lead to rapid destruction of the insulation and creating a pocket between it and the building.

The process of applying is quite simple and does not require special experience. It is important to only have quality equipment, which is able to evenly distribute material over the surface of the Foundation.

The solidification of the polyurethane foam does not take much time. This often requires no more than a minute, so apply the next layer almost immediately. However, to backfill the trench once is impossible. You need to wait a few days for shrinkage.

After hardening of the polyurethane foam can cover it with an additional layer of bitumen. It will only improve its performance and increase service life. You can then cover the trench.

Next you need to finish the top of the heater at a predetermined frame. Operational requirements here, it is only important to protect the foam from rain and sewage.

For a better understanding of the work is recommended to watch this video. It clearly shows the process of spraying polyurethane foam on a pre-coated with bitumen Foundation, demonstrated the design of the trenches and provided many other details in such works: