The contents

In some cases, choose a floating Foundation ↑

The Foundation of any structure designed to distribute the load and carrying the gravity of the entire building to the ground. Today, there are several types depending on the type of soil, size of the building. Consider the so-called floating Foundation, its production used in areas:

- with a low groundwater table;

- for bulk and non-cohesive soils;

- on a heavy, heaving soils.

Another name for such a Foundation – floating plate, since its construction, the technology of reinforced concrete slab, as shown in figure.

It is possible to execute a floating Foundation in a concrete tape:

The advantages and disadvantages of a floating Foundation ↑

The Foundation built in this way will:

- strong and durable;

- practically does not shrink;

- able to withstand very heavy structures;

- the carrier plate can be floor in the basement.

Has his flaws, which are restricted mainly to the high cost and complexity of the work. However, a practical approach to the construction operations can significantly reduce the cost of the work. You can, for example, to renounce the use of concrete pumps and the use of unloading chutes of concrete mixers or to hire low-skilled workers (of course, under control). Thus, it is possible to somewhat reduce the cost of the floating Foundation.

Some types of floating foundations ↑

A great solution is to lay a floating Foundation on clay soil. Being close to the surface, deposits of clay are washed away easily enough. Thus exposed himself built the Foundation. Reinforced concrete floating slab as a Foundation just perfect for this soil: the movement of clay from different processes will not affect the walls of buildings.

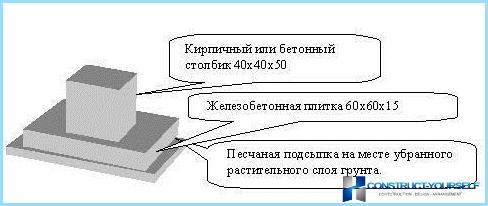

In the construction of light buildings using a variety of configuration foundations, such as the «floating columns».Floating bars used in the construction of wooden baths.This space is filled with Sandstone, impose a concrete slab, and on it are mounted the bars, inside poured concrete.

An exemplary scheme is as follows:

On top of the design set the lower crown of the framework of the bath or beams:

This variant of construction is simple and does not require spending a lot of cash.

How goes the floating Foundation ↑

Before its manufacture, it is necessary to determine the composition of soil on the site and to make calculations of the project.

Floating Foundation with your hands is made in several stages:

- Prepare trench in accordance with the project.

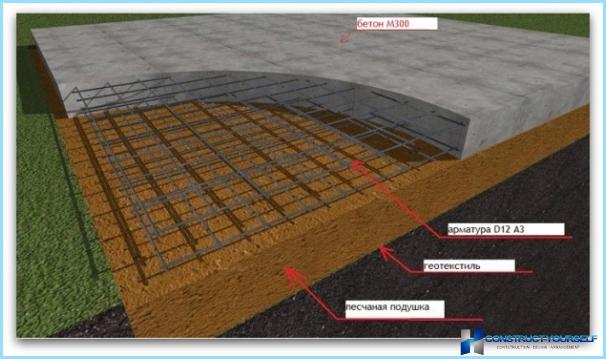

- On the bottom of the pit lay geotextile materials, creating a barrier that will not wash the sand.

- Then poured a layer of sand and gravel, which are wet and trebuutsya. Usually this layer is 20-30 centimeters.

- The next layer is concrete Foundation with reinforcement, its thickness of about 10cm.

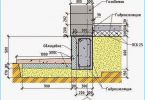

The device of floating Foundation shown in figure:

To have a clear idea how the pouring of the Foundation, to see how to make a floating Foundation, a video on YouTube

To calculate you need to consider:

- The thickness of the concrete slab. For light structures it is sufficient to make the plate height of 15 cm.

- Thermal insulation. The insulator is layered under and over the floating plate, this is the Styrofoam.

- Hydraulic protection. If the water table below 1 metre, waterproofing is carried out using waterproof membranes.

- The pillow consists of two layers. Top – gravel, bottom – sand. Important! In that order. After all, if the groundwater fall under the slab, the gravel does not allow them to stay long and the water leaks into the sand and then into the soil.

The technology of manufacturing a floating Foundation ↑

As indicated above, the laying of the Foundation starts with site preparation – excavation.

The order of execution of works the following:

- Prepare the pillow of sand and gravel. On the sandy soil – 15cm, on clay – at least 30 cm the Sand is dumped into a pit and spread evenly over the area.

For marshy and wet soil part of the cushion made of crushed stone. - The construction of formwork. In order for a floating slab Foundation get quality runs removable shuttering of planed boards with a minimum thickness of 20mm. The corners fastened with screws. With the outer side of the formwork reinforcing struts. Arrange passage for communication.

- Laying of waterproofing. These works are manufactured using polyethylene film, roofing felt or geotextile. The lapped material is deposited on the entire surface, with the sunset on the formwork.

- The reinforcement of the Foundation – a very important stage of building on a floating ground. For small buildings the reinforcement is produced with the help of wire mesh with a cell of 10-15cm. Where would be the load-bearing walls, reinforce with metal rods. For more massive structures used rod of 10-12 mm, while the transverse rods are knit together with wire.

- Pouring the Foundation with concrete. It is produced simultaneously, so the solution must be booked very quickly or mix their own. The concrete mortar is poured in the stacked reinforcement layers of 15 cm, each layer should be carefully leveled and compacted. For the seal layers use a deep vibrator. For a pouring plate not spend more than an hour. Then the concrete is rammed to the appearance of a brilliant wet layer and aligned.

- Drying of the Foundation. This usually requires 4-5 weeks, during this time, the concrete becomes solid. During drying to make sure that the top layer does not dry up and not with excessive. To do this the first day it dipped every 4-5 hours the next day to three times per day, on the third day two times.

- When the Foundation is completely dry, remove the formwork, and give basis to settle the month. Ideally, the Foundation should stand the winter. In the spring you can start building a house.

In order to more clearly present how to pour a floating Foundation videos