The contents

At the turn of 70-80-ies of the last century, the laminate is rapidly broke into «Premier League» outdoor and decorative coatings. The story of its origin, known as «Idea 77», connected with the purchase of one Swedish firm plant for the production of composite coatings. The Swedes experimented with everything that came across under a hand: laminated wall panels, table tops, window sills. Someone during the next «brainstorming» on the subject to be laminated, and came up with the idea to take up floors. A couple of years, IKEA stores introduced the Swedes with the new laminate, which is waiting dizzying success, first in Swedish and then in the world market.

The name of the company-developer of the laminate only remember the experts, the laminate has changed beyond recognition, but the popularity remains huge. Reasonable price, practicality, functionality, good noise and sound insulation characteristics, easy maintenance, great variety of drawings applied to the decorative layer of this floor covering manufacturers in the struggle for the buyer are the components of success laminate.

Today is a laminate multilayer panel, each layer of which «answers» for the solution of different problems:

-

Bottom protects from deformation.

-

The bearing defines noise and sound insulation qualities, moisture resistance and fastens with a lock panel during laying between them.

-

Decorative film is made of PVC or special Kraft paper. This layer is patterned.

-

The top layer of melamine or acrylic resin protects the flooring from damage. Resin can be applied several times, which directly affects the service life of the coating.

The evolution of laminate over the years has affected the ways of joining panels when laying in monolithic floor construction. The adhesive method is almost «goes on stage», today the market is dominated by way of the castle. At the castle the way of the connection spike on the edge of the panel laminate is in the groove on the other panel. The advantages of this method compared to the adhesive are obvious: increased speed of installation, no need to prepare the adhesive composition, in the room there are no smell from the glue. The main advantage locking method enables the flooring to be dismantled and put another 3-4 times (locks Click). There are several types of locks for laminate.

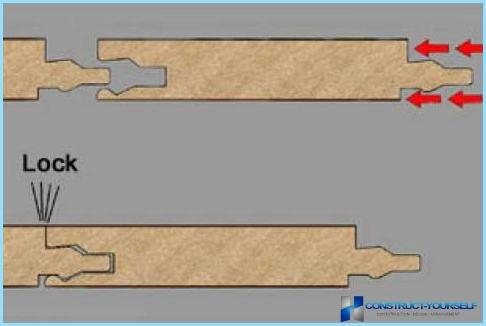

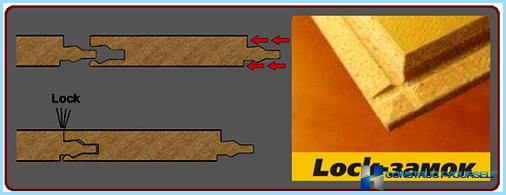

Lock ↑

Lock for the laminate made of the principle «the tongue-and-groove», called Lock. Cutter in one side of the carrier layer is cut out spike, on the other hand, groove with the same brush. It laid on the floor panel, put a piece of timber or a die, and a wooden mallet careful shock are driving the tongue into the groove until it is fully seated and the disappearance of the gap between two adjacent panels. Comb in the groove will prevent the exit of a thorn. A poet of this type of lock is also called a drive. The Lock appeared earlier than other tool joints for laminate flooring and today is considered less than perfect in the technical plan solution.

The relatively weak place the comb in the slot that during operation under the influence of the intermittent load begins to fade. The wear and tear of the castle will lead to the appearance of cracks in this place. Repair of such a defect is not subject. In fairness I must say that accelerated wear of the combs can sometimes be when non-compliance to the base, which fits on the laminate. And here a paradoxical situation arises between this problem and another «the disadvantage» Lock-lock.

This «the lack of» is a certain complexity to paving with a lock of this type. It is recommended to entrust the work on the laying of the professionals, because to act with a mallet should be very carefully adjusting the force of impact. And constantly monitor the connection of the panels. However, a professional before laying shall notify the owner of the premises, that the base under the laminate poorly constructed and during operation there are problems. And when properly constructed base service life of the tool joint will be closer to the lifetime of the panels.

Lock-lock is a well proven for a long time the model of the tool joint, besides the economical.

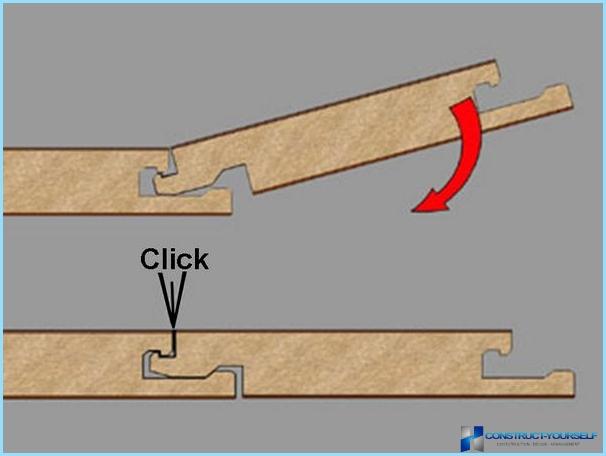

Castle Click ↑

Further improvement of the laminate was marked by the appearance of the locking system Click. This lock different from its predecessor Lock-lock a form of pile. The pile in this case, too, is produced by milling and has the shape of a flattened hook. Panels attach to each other at an angle (usually the angle is 45°, but from different manufacturers it can vary). The panel with the tongue is lowered, the tongue engages the groove and hear a distinctive sound. The sound and gave its name to the castle – Click.

Effort great to make when joining the panels is not required, to knock out the panel with a mallet is not required. They are securely fixed, in the process of laying the locks remain intact even if the human error involved in working with the coating. A reliable connection of adjacent panels and the resulting DC voltage protects lock from abrasion during the whole period of operation. Accordingly, the gap between the panels over time do not appear. The undoubted advantage of the Click locking system – possibility of disassembly of the floor covering and re-Assembly. And so to 3-4 times.

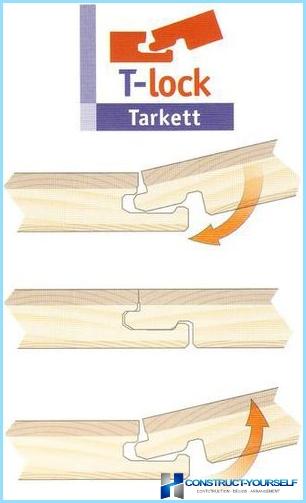

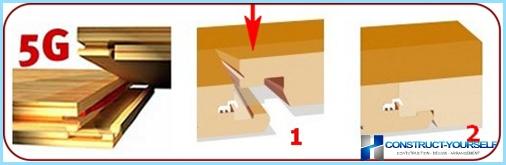

Locks T-LOCK and 5g ↑

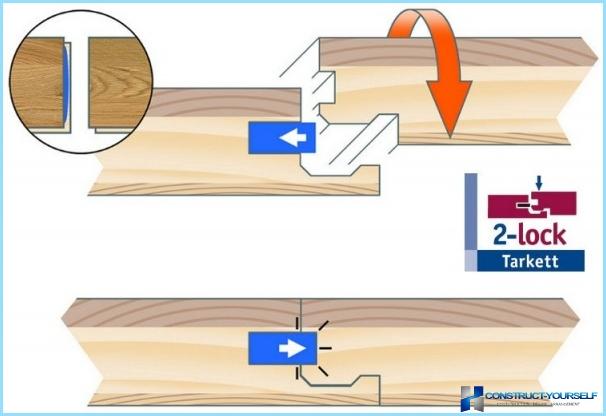

Manufacturers continue to improve the locks for laminate and are developing new modifications. Thus, the company Tarkett has patented a system in which the lock is cut by the cutter in the carrier layer of the panel, that Click. The fundamental difference is the presence of the castle on the long and face sides. Styling repeats the steps of connecting panels, Click-lock, a new panel is applied to the already laid floor an angle of 45°, is lowered and latched.

The next upgrade of the castle for laminate – 5g system. To this castle came all the leading manufacturers – the aim was to further simplify the styling process with no loss in strength and link quality. At the end of the panel to install a movable tongue, which provides simultaneous connection of panels along the long and short side. On the long side panel is fed at an angle, and with the end just overlaps the top and goes down until it clicks tongue.

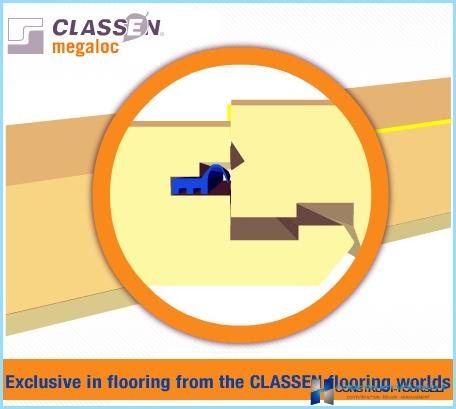

Castle Megalock ↑

A kind of lock for 5g laminate system of the German company Classen. The first row of panels is laid along the length, the next row is applied at an angle to insert the tongue into the groove of the laid panel and then the panel is lowered and latched the lock in the end. Disassembly of the stacked laminate, if necessary, to make it easy.

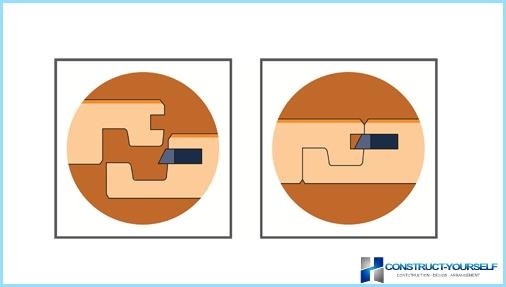

Aluminum castles ↑

The Swedes invented laminate, their neighbors, the Norwegians have developed an aluminum locking system for him. Traditional connection «the tongue-and-groove» Lock-lock supplemented by a castle on an aluminum profile. Pile this castle is in the second groove on an adjacent Board. Aluminum profile can be located on the bottom of the Board or placed in the carrier layer. The dual compound allows to avoid deformation and the appearance of joints when laying and during operation. Aluminum lock can withstand the breaking force of the one ton and more. In addition, such locks for the laminate provides additional protection to the flooring from moisture.

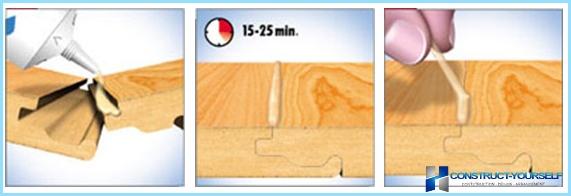

Handling locks the sealer when laying ↑

Leading manufacturers produce laminate flooring with the additional protection of joints from moisture wax compositions. This applies to laminate 32 and 33 of the class. Make the protection of joints when laying the sealant should be in those cases where there is no covering them with wax.

Modern sealants have high strength and elasticity, can be used in a wide range of temperatures, contribute to prevent the emergence of creaks and gaps, easy to use.

In addition to the components designed to combat fungus and mold, and various mechanical additions, in modern sealants added dyes. Therefore the sealant does not require additional painting in tone stacked laminate after application.

Conclusion ↑

The quality of laminate flooring depends largely on the durability of all outdoor construction. And its appearance. In addition, chosen with knowledge of the case, the lock type will greatly simplify the process of laying a floor covering.