The contents

The popularity of laminate from year to year. This type of flooring attracts consumers by its functionality, practicality, ease of installation and subsequent maintenance. The laminate has good abrasion resistance and durability, sound and thermal insulation properties. Manufacturers are constantly improving system interlocks panels cover, which makes its installation simple and convenient.

In the struggle for the buyer of the laminate manufacturers are constantly updating collections produced, improve ways of applying the patterns on the decorative layer of panel covering can imitate natural wood, natural stone, ceramic tile. The market represented a huge selection of surface textures and colors. Improving the technology of deposition of the upper protective layer of synthetic resin with the addition of microparticles of ultra-hard minerals and antistatic qualitatively changes the operational characteristics of this flooring.

The main advantages of laminate is its relatively low cost.

The demands of the producers to the substrate under the laminate ↑

The basic requirements of manufacturers to the basis on which will be laid the laminate are as follows:

- The base should be solid and stable.

- The base should be smooth.

- The base should be dry.

Some respected sites devoted to construction issues, mistakenly refer to the fact that in SNiP 3.04.01-87 «Insulation and finishes» standards for laminate flooring not specified. However, they are listed in the rulebook 29.13330.2011 «Floors», paragraphs 5.18 and 5.19.

Is it possible to put laminate on screed? ↑

Rightly considered, that the sand-cement screed and laminate «friends» and that the coupler meets all of the requirements for the surface that will be laid floor covering.

Indeed, the screed strong and stable (we’re talking about quality made screed). Humidity it before installation you can check the hygrometer, or electronic hygrometer, and in the absence of these devices «folk» way with a cloth. In practice, however, even qualitatively performed screed do not always correspond to the requirements of the largest changes in height.

The differences exceed 2 mm? But just a couple millimeters, it’s a trifle! For such a laminate «detail» will result in rapid wear of tool joints and the appearance of cracks between the panels, loss of appearance. Because the substrate will not be able to compensate for the unevenness of base.

Therefore, in cases where sand-cement screed not only meets the requirement for flatness, to align the surface of the screed a thin layer of self-leveling floor (for example, Vetonit 3000 or LITOKOL S5), pre-treating the surface with primer deep penetration. Poured self-leveling floor is leveled and rolled with the spiked roller. Drawing attention to the fact that the plane of the screed after alignment self-leveling floor was horizontal.

The substrate under the laminate ↑

The purpose of the substrate for the laminate to prevent contact between the substrate surface and the flooring, providing additional sound and thermal insulation and, in some cases, protection from moisture.

So is it possible to lay laminate flooring straight onto the concrete? Only laminate with integrated substrate. As a rule, a laminate of 32 or 33 classes. However, even this laminate flooring is better to put the pre-Packed plastic wrap. The fact that the coupling gives all residual moisture in the next 2-3 years. Although outwardly it may look completely dry. To prevent contact of the laminate with the remnants of moisture from the screed and used a plastic substrate.

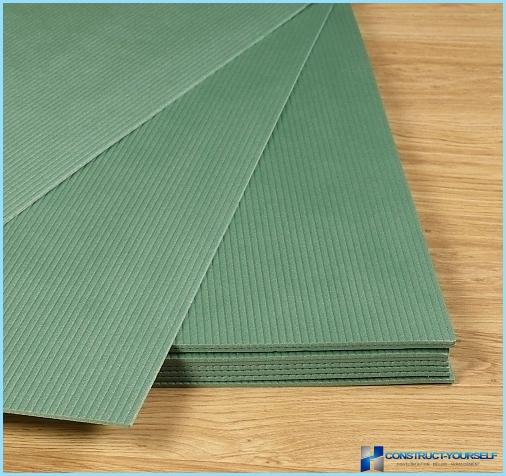

If your laminate does not have an integrated layer of the substrate, you can use any, according to your possibilities: cork, lisinoprilbuy or bitumen-cork composite underlay Tuplex, foil, extruded polystyrene, which is ideal for laying on a concrete floor. Characteristics it is superior to polyethylene foam, but is more expensive. Less crushed and deformed. It is believed that the substrate is extruded polystyrene loses its properties after 10 years of operation. During this time you will decide to change the laminate.

Ways of laying laminate flooring ↑

In order to determine the correct amount of laminate flooring to the area of the room is added 7% when laying the flooring perpendicular to the light source (the window) and the 15% for a diagonal installation. Diagonal laying and laying across used in small spaces with the aim of visually expand the room.

Styling methods:

-

Perpendicular to light source (long side panel is located along the light rays). In this way, the seams between the panels less noticeable.

-

Parallel to the light source.

-

Diagonally.

-

Christmas tree.

For the laying you need:

- A jigsaw or handsaw.

- Knife for opening packages.

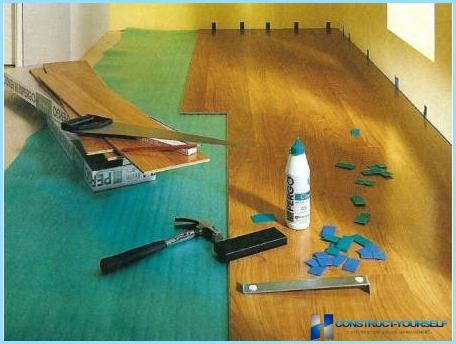

- Plastic wedges.

- Steel bracket with which you will be able to fit the end of the last panel in the row. Without brackets it will be very difficult.

- Roulette.

- Gon.

- Mallet and die (for lock Lock).

- Pencil.

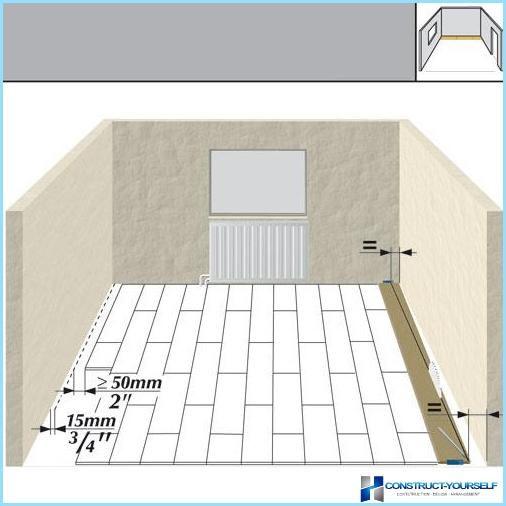

First set of plastic wedges. They will help to provide the necessary gap of 10 mm between the laminate and the wall. From the corner of the room from left to right is placed horizontally the first row. The comb panels of the first row are directed towards the wall. Panels are joined end side. Latest in a series of panel cut with a jigsaw, or a hacksaw, and put in a number.

Starting the next row can be the remaining piece of the panel (provided that its length is greater than 300 mm). It is important that the seams in adjacent rows do not coincide.

The first and second rows are joined. When using panels with Lock-lock, you will need to tamp them with a mallet (through the die) for fixing of the ridge in the groove of the next panel.

Panel system Click are stacked under an angle of 45° until it clicks into place. This coating can be removed if necessary.

Panel, the last row will need to be cut to width in size. Pre-view how to cut the panels of the last row. The floor will not look good if the width of the panels of the first and last rows will be very different. In this case it is better to trim panels and the first and last rows. Remember that a cut line will cover the plinth, so that small irregularities in the location of the cut is not terrible.

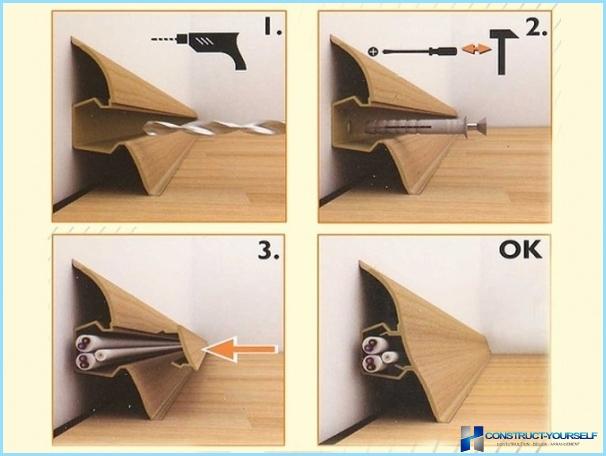

After installation, the wedges are taken out and mounted the plinth.

Conclusion ↑

The laminate is placed on the leveled, the screed dry without defects. Pre-screed is laid a sheet or roll of substrate. Mandatory vapor barrier layer, which you can use plastic wrap. With the right device floor screed difficulties with the paving occurs. The use of a laminate with a locking system Click 5g or Megalock will make the installation process simple and quick.