The contents

- Laying of the substrate

- The choice of method of installation

- Laying laminate flooring with different types of locks

Manufacturers of laminate in their advertising campaigns emphasize that the installation of this most popular floor coverings has become so simple that it will cope with any person. Whose experience with the laminate does not. You need to read the instructions, watch the promotional video of company, and as a result of your work room with the new floors, will quickly be transformed, and delighted family will praise your construction achievements. Despite the fact that prior to the installation of flooring your success in this field differed little from the ability of one of the characters of the English writer Jerome K. Jerome uncle Podger to hang pictures.

Indeed, the improvement of systems interlocks panels greatly simplify the installation process. If laying laminate flooring with lock Lock requires a certain amount of experience and skills, the next generation of locks – Click – of such requirements does not show. And on the market for sale laminate with locks 5g and Megalock, and even with aluminum locks. Soon everything will be in Russian fairy tales, when you only need to put packing in the room where it will be mounting, and to hold the flooring without opening the box, a couple of days. To adapt to the temperature and humidity in the room. And then open the packaging, and the panels themselves fit «according to pike». But the devil, as you know, is in the details.

Laying laminate flooring ↑

The work on the installation of flooring has become much easier. What can be said about the preparation of the base before installation. The Foundation must be level, stable and dry. The difference in height of say in the range of 2 mm to 2 M. In some cases requires waterproofing before laying underlay and laminate.

Laying of the substrate ↑

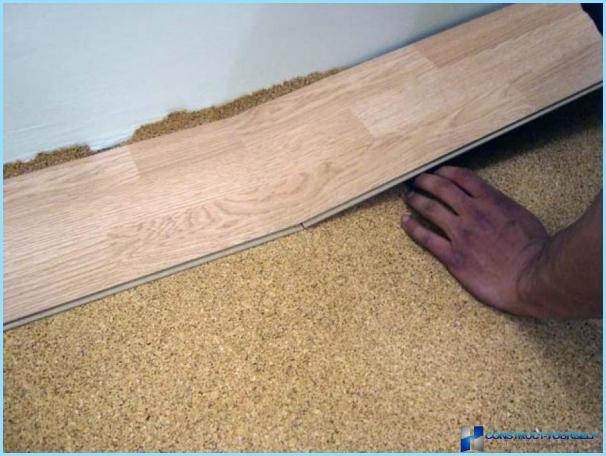

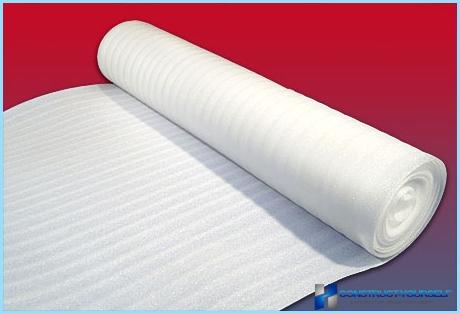

The substrate different in material from which they are made, characteristics and cost:

- Cork – the best properties and the most expensive option.

- Of bitumen sheets containing particles tube – combines the waterproof properties and characteristics of cork underlay.

- Foam for extra strength – quality and affordable.

- Plastic – the budget option with good features.

The producers assure that the substrate is able to level the ground under the laminate. This is an exaggeration. The substrate needs to provide heat and sound insulation. Minor irregularities leveled the old wooden floor or bottom of the plywood substrate can compensate, but not more than.

The choice of method of installation ↑

Recommended for 2 days to keep the packaging laminate in the room where it will be installed. So he will get the humidity and temperature of the premises.

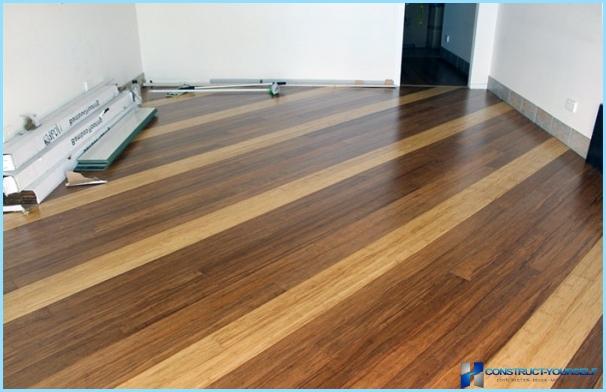

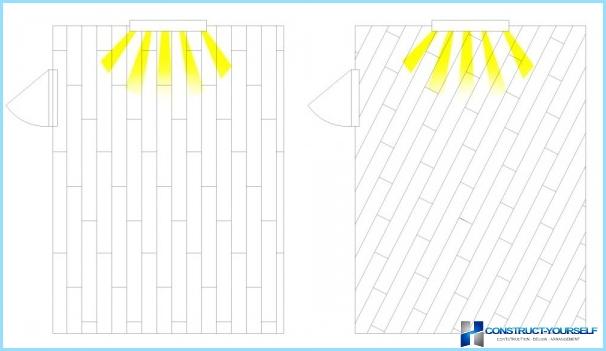

Determine a method of paving: diagonal, perpendicular or parallel to light (along or across the room). Mounting diagonally is often used in narrow spaces – this is one way to visually expand them.

It is customary to lay the laminate perpendicular to the light source (long side along the flow of light) in the room is a window. In daylight the joints between panels less noticeable.

However, when installing roofing on a wooden floor it is necessary to focus on the direction of the floor boards. On a floor the laminate is laid perpendicular to floor boards to reduce possible deflection. If the old wooden floor covered with plywood to install the floor follows the traditional way – perpendicular to the window.

A small, narrow spaces without natural lighting (corridors, hallways) laminate stack across to the room to visually expand.

Laying laminate with various types of locks ↑

For the laying you need:

- A jigsaw or handsaw.

- Knife for opening packages.

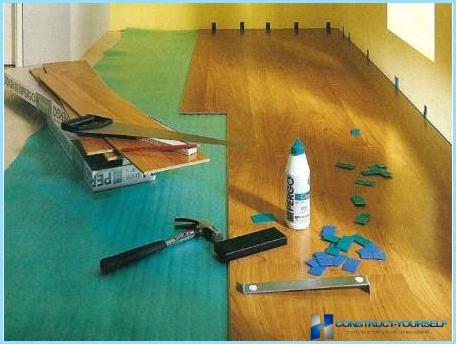

- Plastic wedges.

- Roulette.

- Gon.

- Mallet and die (for lock Lock).

- Pencil.

First set of plastic wedges to meet the gap of 10 mm between the laminate and the wall. From the corner of the room from left to right is placed horizontally the first row. The comb panels of the first row are aimed at the wall. The panels are connected end sides. Latest in a series of panel trimmed with a jigsaw or handsaw and placed in a row. Starting the next row can be the remaining piece of the panel (provided that its length is greater than 300 mm). It is important that the seams in adjacent rows do not coincide.

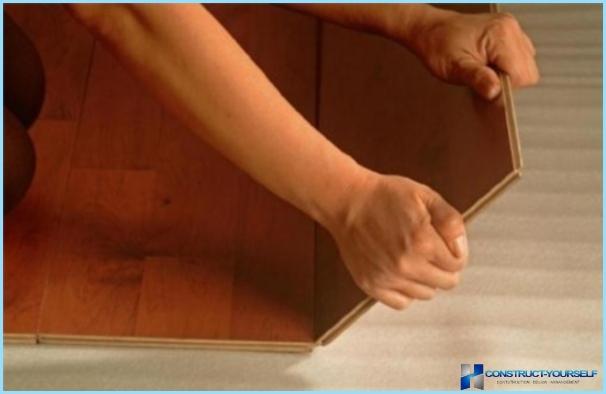

The first and second rows are joined. When using panels with Lock-lock, you will need to tamp them with a mallet (through the die) for fixing of the ridge in the groove adjacent pane.

Panel system Click are stacked under an angle of 45° until it clicks into place. This coating can be removed if necessary.

Panel, the last row will most likely need to be cut to width in size. Remember that a cut line will cover the plinth, so that small irregularities in the location of the cut is not terrible. After laying laminate on the wooden floor, the wedges are taken out and mounted the plinth. Pre-view as I need to cut the panels of the last row. The floor will not look good if the width of the panels of the first and last rows will be very different. In this case it is better to trim panels and the first and last rows.

Conclusion ↑

The basic rule – laying the laminate must be made of the long side panels along the flow of daylight, in other words, perpendicular to the light source. This is done so that the joints of the panels was less noticeable. This method of installation also helps to visually increase the length of the room.

For a visual enlargement of the room laminate flooring is laid diagonally, but in small rooms without natural light – across the room. Laying across or on the diagonal to visually expand the width of the room.

Laying laminate on a wooden floor is made across the direction of laying floor boards.