During major repairs or construction of the house, the question arises whether it is possible to put a warm floor under linoleum. Such a safe form of heating for households. It should be noted the existence of several types of floor heating, which are installed under the linoleum, laminate or tile floors. The main thing is to know the features of the material, whether it is possible for linoleum to put a warm floor, how to carry out preparatory and Assembly work, and whether skills and knowledge to efficiently and long served warm floor.

Kind of a warm floor ↑

People constantly strive to improve their own living conditions and a warm floor is no exception. Today, there are varieties of floor heating.

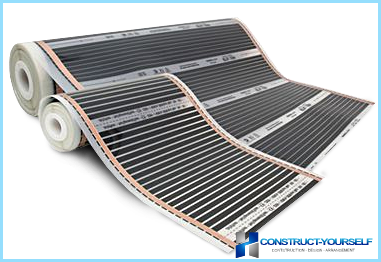

Infrared film material ↑

The heating element of the floor is a film or a special cable that connects to a network via thermostat.

This type of floor is used in shops, office premises, industrial facilities or in residential areas. It is installed as an auxiliary or primary heating. This versatile floor heating, which can be installed under any flooring material, including under the linoleum. Under ceramic tile experts do not recommend it to put.

Another advantage lies in the flexibility and elasticity of the fuser that allows to heat the surface in a vertical, horizontal or even inclined position. Such material is almost not subjected to mechanical damage.

Set film warm floor under the linoleum is simple and will not need a lot of time. To install it enough to be self-leveling floors, and film material to lay 75% of the floor surface.

Electric floor ↑

Classic look and warm design, which is constantly modernizarea. It involves the use of cable and is ready of heating sections, a small size. On top of the electric floor you can lay linoleum or laminate, carpet or ceramic.

Water floor under linoleum ↑

This type is often installed in a private home or cottage. To the apartment to install such heating, it is necessary to take care of additional riser. Water that passes through the system of floor heating, in General, the riser will be returned cool, so the neighbors will get hot and cold water. Today, water-heated floors installed in new homes, where connection design is already equipped with special risers for heat transfer.

The main advantage of this system is saving power, as well as the lack of harmful effects of magnetic and electric fields. Compliance with all the rules of installation of Underfloor heating will allow you to perform the work without difficulty.

How to install warm floor under the linoleum ↑

Each floor heating system provides for preparatory and installation work.

Manual preparation and cable installation warm floor under the linoleum ↑

To undertake preparatory activities. Remove old floor and screed the dust and debris.

To choose the place where you will install the thermostat. To it to supply power and ground cable.

Lay a waterproofing material with the allowances on the walls above the level of a future tie. In places where it will come into contact with the wall, glue the ribbon to compensate for in order to remove the unpleasant consequences of the expansion of the mixture.

Lay insulation material, which helps to reduce the heat loss of the floor. If this is an additional heating, as the insulation material used a substrate made of polyethylene foam. If the main heater, then the insulating material is expanded polystyrene with a thickness of maximum 5 cm. To the balcony to need the heater, size 10 cm.

After warming creates a rough screed with reinforcement, which is placed on foil and roll of insulating material with foil covering.

The installation of the heating element is carried out after calculations of the size of the step installation. To fasten and secure the wires uses a special tape.

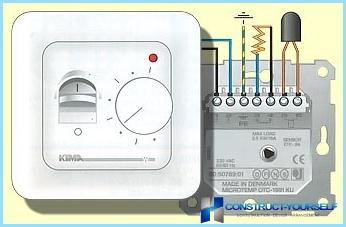

By means of coupling clips power cables thermostatic device and heating system, set the temperature device.

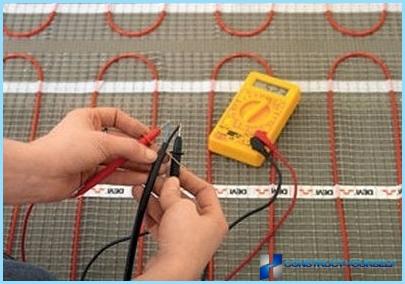

Heating the highway are placed strictly by the rules. The branch line shall lie at a distance from each other by 7.5 cm, the curves of the cables should be smooth. The distance to any objects should not exceed 10 cm, and the heating elements is not greater than 20 cm In areas of movable joints cable placed in a plastic pipe to prevent it from tearing. After laying the floor to be visual and testing inspection of material integrity.

Poured cement-sand screed.

For finishing of the floor tiles used, natural or artificial stone, linoleum or laminate.

Video example of how to perform the work on laying cable sex:

Instructions on how to install the water floor ↑

The surface is ready and level, remove the old floor and the screed, the remains of a bituminous material and other debris. Creates a new screed and waterproofing.

At the perimeter of the floor glued a special tape that compensates for possible expansion in the heating process of concrete material.

Placed insulating material depending on the thickness of the slab, the location of the premises and the type of covering on the floor.

Water pipes placed on the Foundation prepared in advance, and fix on the floor with clamps, using screws. For fixing pipes to the reinforcing mesh used plastic straps. Not to bend and to deform the material, it is gradually unwound, and bend. The damaged pipe can no longer be used.

Connection of floor heating to the manifold is through EUROCONTROL system or crimp fittings.

A full system check, water for days at a pressure of not more than 5-6 bar. If all is well, creates a screed of concrete with a thickness of maximum 5 cm.

To install warm floors water-based under the linoleum should be as thin as possible a layer of screed, this allows you to Supplement it with mesh, laying it over the design.

At ease contractors floor installation independent forces to verify video:

Manual installation Underfloor heating film ↑

In the first stage, the preparatory work remove the old floor if it is physically worn out. If the material is in perfect condition, then it is enough to remove dust and dirt.

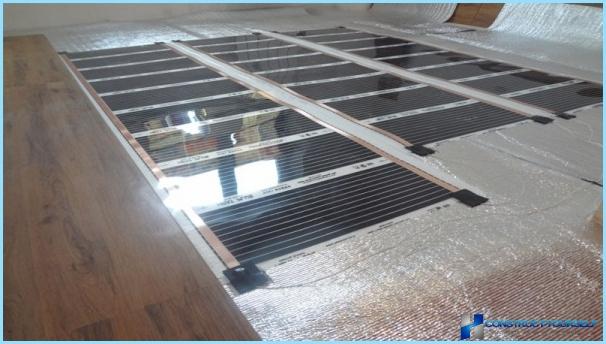

As thermal insulation material, under linoleum or laminate experts recommend to lay insulation foamed product with a thickness of 3 mm.

The installation process for film floor under linoleum provides the use of a substrate which is placed so that the metallized side was facing down on a clean surface. Immobilize the insulation should be double-sided tape or with special glue. Between a strip of insulating material connect the simple tape.

Temperature of floor heating controlled by a thermostat. It must be chosen in accordance with the calculated power, focusing on how to consume electricity, one square meter of the film, is about 200 watts. To know the capacity of the thermostat it is necessary to multiply the amount of energy one square meter of the total area of the room where it will santilata film on the floor. The thermostat control and program the operation of heating the entire floor.

Film warm floor is laid only on the usable area in the room. If the heating is additional then enough 50% of the total. If the design will perform the function of the main heating, then covered 80% of the total area of the heating material. From the wall to keep the indentation no more than 20 cm, and near the furniture or appliances film under the linoleum and do not stack to prevent overheating.

The material is applied directly to the insulation, using brightly colored tape. From the point of view of a professional look, the canvas should be placed along the room in order to reduce connection points of wires. All the segments are arranged strictly according to the scheme, avoiding overlap even at the edges.

The squares film is fixed by means of double-sided tape to prevent the shift of the fragments.

Under the sheet is installed the temperature sensor near the expansion device. It is recommended to make a hole in the insulating layer to avoid bumps.

All the elements of a warm material, foil and wire are connected strictly according to the scheme. The canvas breaks a copper clip that holds it together with a copper strip which is provodnikovym element. To test the durability of the clip, it is enough just to pull over. In regard to film material, he must not move. On the clamp clip the wire and close it, using bitumen of isolation of the two sides, then tightly compresses it.

To properly connect the floor heating, thermostat and wire, it is better to seek the assistance of a specialist electrician.

Check the whole construction of floor heating using the test mode. Insulation material must be reliable, places where cables are connected, a special test device. After a warm floor is connected with an electric network, the heating of each strip is checked separately.

Will complement the theoretical part of the installation film sex video clip: