The contents

Often the fencing for parks, gardens, farmlands are used welded wire fences. They are not as pretty as forged sections, but despite this demand and popularity. There are many types of welded fence, they differ from each other installation.

Advantages of welded fence:

- has strength and durability;

- attenuation of the reflection shock (for example, if the design has entered the car);

- fire safe;

- not throwing shade on plants growing next to it.

- in conjunction with climbing plants to create a landscape composition.

Cons:

- does not protect from wind, dirt and prying eyes;

- need anti-corrosion treatment;

- if the installation requires skill with the welder.

More details can be found in video:

Varieties of welded fence ↑

In the construction market, a buyer can find many options for welded sections. They are divided into:

- reinforcement of profiled pipes;

- sectional welded fence;

- welded fence mesh-netting;

- welded fence made of metal profile;

- decorated welded fence;

- Cavanaugh-welded fence.

Reinforcing welded wire fence is the simplest and cheapest option. Advantages – ease of manufacture and ease of installation. Cons – looks unattractive. Normally fences made of rebar are placed as temporary structures.

Another budget option fencing is the welded fence sections is a more refined version of wire fencing fittings or corrugated pipe placed in pre-prepared frame. Its installation is quite simple and will not take much time. It looks aesthetically pleasing and attractive, in addition, this fencing will protect your land from the invasion of uninvited animal.

To order more aesthetic and attractive looks welded metal fence made of metal profile. Its manufacturing process is more time-consuming and requires considerable financial costs, but in the end you will get a durable and attractive design. Will appreciate this version of the fence lovers of privacy, because the section of the metal profile opaque. But gardeners consider it a disadvantage that due to the shadow of the sections not plant trees and vegetable crops, because it will hinder their normal growth.

Welded wire fences with decorative trim are the most beautiful, but it is quite expensive. Many craftsmen engaged in decorating yourself, this allows to reduce the cost of the process.

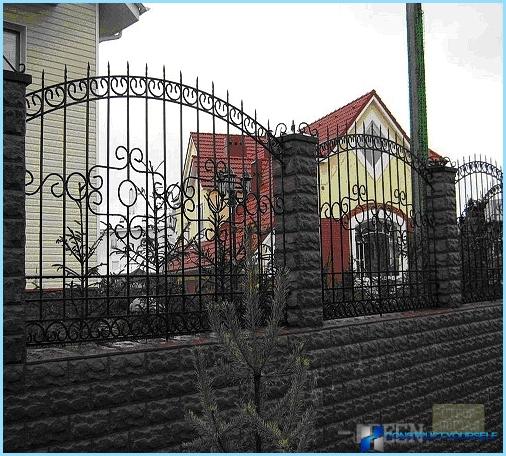

If you do not think about the financial side of the question, then you can order a wrought-iron fence. It will serve you as long as possible, you can not be afraid that it will touch the corrosion. Also a plus wrought-iron fence that he does not need decorative elements.

You can buy a ready-made welded fence or make a partition yourself.

Make welded fence with their hands ↑

For support columns, welded fence suitable natural stone, brick, metal, pipe profile 15×15 or 40х20 mm, or steel strip 25х4 mm. If the support to use metal pipes of small diameter, they can not withstand the weight of the structure and bend. Large diameter pipes do not look very attractive, so experts recommend choosing a square shaped tube. Their edges create rigidity and provide additional strength and resistance to bending.

Before installation it is necessary to carry out preparatory work – obmerte and mark the territory under the fence, cut the metal required sizes, dig a Foundation, set the posts and pour base.

Bearing bars shall be at a distance of two meters from each other. The spans between columns should be equal, so count like this: measure the distance between the edges of the site, divide it by two and you get the required number of columns.

Then you must calculate the height of the bars. If you put a fence made of metal profile, its height will equal the height of the sheet. In other cases, the optimum height is considered to be one and a half meters. A fence of this height will protect you from the invasion of the neighbor’s animals and intruders. The height of the bars should be 40 centimeters longer sections (the bars go into the ground at this length).

Tubes are sold in standard lengths of 3 m, 4.5 m, 6 m fence above two metres will fit a three-meter pipe, and supports other lengths can be cut to desired dimensions directly from the store – cutting is inexpensive and greatly facilitates the transportation of the material.

When pipe is purchased, you can proceed to the next stage – preparing the pits for the Foundation. Dig them brown (garden or electric) with a screw diameter of 20-25 cm, depth of the pit should be 40 cm In dug holes, insert the posts and push them into the soil to 30 cm At performance of works do not rush and do everything slowly, because it is important that the bearing was perfectly smooth.

Then you need to prepare a concrete solution (ratio of cement and sand 1:3), for strength it adds broken stone or fine gravel. For additional stability, the hole poured sand-gravel cushion 10 cm Fill holes with solution, and leave for 3-5 days.

Installation of the reinforcement welded fence ↑

Tools needed: apparatus for welding, a set of electrodes, metal saw or an angle grinder, gloves.

Reinforcing a fence structure is unreliable, it is used as a temporary structure. For a more robust design is necessary to use reinforcement bars with the diameter more than 1 cm or profiled pipe.

The installation of the fence occurs in stages:

- measure the dimensions;

- cut the pipe or fittings;

- welded.

Also need to address the designer issue. Easier to mount the pipe horizontally to the ground surface, but often the rods are parallel to the columns. If you choose the first option, the pipe length should equal the distance between the supports, and if you choose the second option – the height of the pillar. Also for the second option you will need two pipes that need to welded to the columns – they are the reason for all rods.

First welded to the bearing bars. When welding follow the continuity of the seam – if a poor contact or arm broke, it is better to fight off the detail and weld again. Then the beams are welded the bars, they must be at the same distance from each other and have equal length. How to weld – internal or external – on the technical characteristics does not matter, it all depends on your desire.

Installation of sectional welded fence ↑

Sectional welded fence is mounted about as well as fencing mesh. Some immediately after installation of the bars welded to it a grid, but doing so is highly undesirable for several reasons:

- such a structure is easily damaged;

- mesh quickly will become deformed and to hang out;

- the mesh is easy to bend and crawl under it.

Therefore, sectional fencing is more practical than the fence or mesh. Phased installation looks like this: installation frame, fixing the ceiling, installing partitions.

For the construction of the frame is better to use metal corners, first, they are lighter than the pipe, and secondly, they hide the weld. The height of the frame must be the same as the fence, and the width is 5 cm less than the distance between the supports. Externally it has a rectangular shape. Used for ceiling fittings, shaped pipe or mesh. The latter option has the least weight, so it is chosen most often. Whatever ceiling you choose, you need to cut it at the inner corner and weld over the entire interior surface area. Follow the continuity of the weld is to pull it out when welding is impossible, as then weld the re-rod or grid will not work.

Welded wrought-iron fences and decorative elements ↑

If you plan to put welded fence for many years, you can opt for forged design. Plus, this fence is that it has the appearance of a high-level, excellent technical characteristics (service life up to 50 years durability), section easy to install. The downside is that the price of such partitions is very high. But you can compromise and order only decorative forged elements (spikes, patterns, shapes, edgings, caps on fence posts) and to weld them to the fence sections. This option is cheaper than the ready section and is mounted easily by yourself.

Tips for installation and maintenance of welded fences: ↑

- Wrought-iron fence to look aesthetically pleasing metal supports with round or square cross-section. If you selected a column with a circular cross section, the optimum diameter is 76 mm, and if a square cross-section, the recommended size 60×60 mm.

- To avoid falling precipitation in props, use special plugs or the top of the post brew.

- Do not forget to handle the fence anti-corrosion agents.