The contents

- To make the choice of construction

- To make the project on the model

- Let’s do a corner fireplace with his hands

- How to make the clutch

- Styling technique series

- Norms of consumption of materials for laying brick

- Important aspects of the fireplace

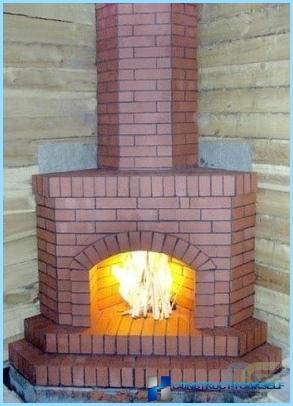

The presence of a fireplace in your home adds comfort and challenges in roughly equal parts. However, installation in houses or even apartments fireplaces, and often a corner fireplace, is gaining popularity. What is so good about a corner fireplace? The major advantage is the use of one of the «blind» areas of the room. Corner fireplace is simple to manufacture, has a high tolerance built and has good traction in the channel burning.

To the negative sides of the corner fireplace include:

- Low thermal inertia through which a corner fireplace quickly loses the accumulated heat;

- Low coefficient of fuel use, much of the heat goes out the flue pipe;

- Requires the use of high quality bricks and the binder solution.

In the work corner fireplace work more like a stove than a Russian stove. Due to the small dimensions corner fireplace is not hard to do even in a small room, it will take a lot of space and quickly warm in the cold. The best corner fireplaces for home on wood fuel is small in overall size and have no decorative excess weight in order to make them appearance more effective.

If you need corner fireplace for use in the living room, as pictured, is to make a choice in favor of the services of a Mason-a Builder or a professional decorator, the complexity of the work will be higher than what you can do with your hands. The housing options are required to make an exterior chimney on the outer wall of the building. It is costly and expensive, but it is achievable. In the event of a chimney it is possible to use a ready-made solution industrial production of clad iron. A great example of this option can serve as a corner stove «Bayern», designed to be used mainly in attics and apartments.

To make the choice of construction ↑

The best option for installation is the second closest corner to the front door. It is not necessary to place the fireplace in the corner by the window. In this case, to heat the room it will be difficult, and to all, a fireplace will make the unpredictable direction of the air flow, which will affect the ventilation.

If a corner fireplace is supposed to do in the apartment, tune in to a long Association with fire and building inspections. Largely a place for the installation of a fireplace depends on the possible output of the chimney on the roof. For the outlet of the flue in a side wall, it is necessary to make electric exhauster.

On the contrary, for corner electric fireplace the best option is to place near the inlet opening of the ventilation or close the window.

To make the project modeled ↑

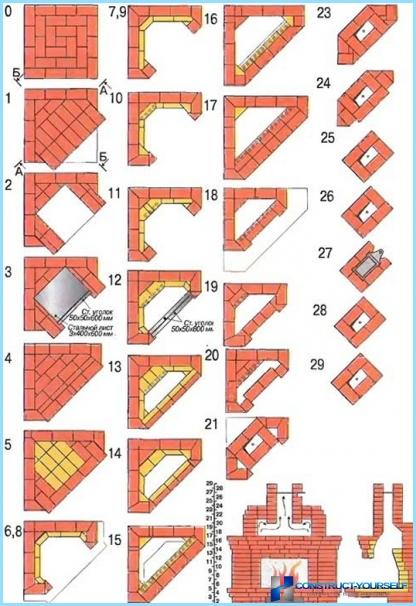

If your plan is to make a corner fireplace with his own hands, dismantle the scheme porjadovki and General drawing of the fireplace to detail. To do this, you should use a ready-made project done by a specialist. The best option would be borrowing plans on a contractual basis from friends, actually embodied the project in stone and to make certain conclusions from its use.

With their hands can do everything, but before starting work, make yourself a step by step instruction to work with their hands to build a corner fireplace. This will help to evaluate the labor, time and cost of the intended material. For the corner fireplace, which are assumed constant use, you can make option based on cute, practical, and reliable corner wood-burning fireplace with a cross section of the furnace in 26дмTwo.

Main features:

- Corner fireplace in the sizes does not exceed 95х95см, at the height of the body and pipes at 120-130cm. Sole the fireplace can be supplemented with a metal mesh for the storage of fuel and a box to remove the ash;

- Combustion chamber size 55х38см and depth in the 27-30cm is designed for quality dry firewood. At this size the height of the chimney shall be not less than 4m Internal section of the chimney must be at least 200cmTwo. The cutoff of the chimney above the level of the roof ridge to make no less than 40cm;

- A single loading of the combustion chamber allows «start» Parking for 20-25min. Optional glass removable door will improve traction and efficiency. For normal operation in the camera base placed steel or iron sheet with a thickness of 6-10mm.

In the English versions is often installed cast-iron burner with reflector, ash pan and grate. Can very effectively warm large spaces, they are reliable and have a long service life. Almost all of them are intended for the use of coal combustion or coal briquette. Sometimes even have built-in fuel hoppers, allowing the fireplace to make continuous burning for more than a day. But in the wood version is a little superior to designs with fireclay lining.

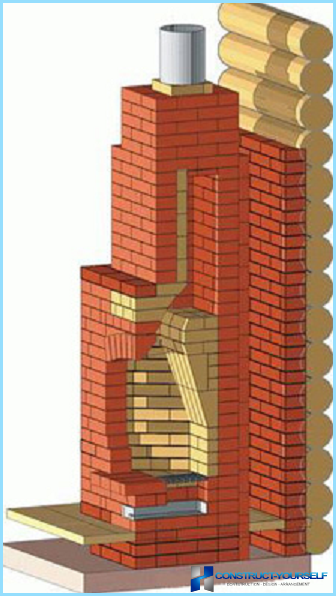

The masonry of refractory bricks are trying to perform, not tying up with the ceramic, due to the large difference in temperature.

Let’s do a corner fireplace with his hands ↑

Building traditionally begins with the preparation of the Foundation and execution of waterproofing. Given the project enough to make a ditch with a depth of 30cm laying at the base of rubble stone. In addition to a solid Foundation, it is extremely important to do fire unravel the back-side surface of the fireplace steel sheet or heat insulation material.

How to make the clutch ↑

Important and fundamental aspects of the brick laying in a little bit, but it takes endurance, patience and strict adherence to them. First, by means of a plumb and level gauge you need to have the dimension chain of masonry and brick horizons series. Second, cutting the size in half or cut bricks safely make the segments using the grinder.

The technique of stacking rows ↑

Any line starts from the rear wall and in the process of forming the first layer is performed without a binder, with stacking spacers on the layer of the solution. Initially, the sand-clay mortar is laid the Foundation, according to porjadovki the fireplace. To make the lining more difficult, but processed fireclay easier and simpler. The lower and poorly heated layers can make a clay mortar with a little cement additive.

To make the arch, the bricks have to be cut by 6-10on and put on a special mandrel that is installed on the profile flange width of 75mm. To perform this procedure requires little prior training, due to the fact that mud is soft and there is shrinkage of masonry with sagging bricks.

To build the smoke of the tooth of the bricks pre-spread on the plane, chalk it is necessary to make a cut line and be sure to number the number and position. The segment can make an angle grinder or the machine.

Norms of consumption of materials for laying brick ↑

For a simple project corner fireplace, his hands will need 350 red solid bricks and 120 of the refractory ШБ38. To make the lining a wood burning corner fireplace, you can use any of the available refractory materials. But the easiest way to work with chamotte. Refractories «Dinas» or «Backer» it is very difficult to do in the required size due to high hardness, they are designed for industrial furnaces and are made of large heavy blocks.

It is recommended to purchase a brick is not below grade 200 with a small margin to the marriage and fight. Just need to make a selection of the most successful instances of brick for the front side.

For a corner fireplace, you will need up to 200 liters sandy-clay solution, the third part to be put aside for the preparation of the binder on the basis of the refractory powder.

Important aspects of the fireplace ↑

Even the most detailed design and calculation will not correctly take into account all the nuances of the architecture, despite its simplicity, is a complex thermal structure. In the angle of the fire should be to focus on three components:

- Having a good positive draft in the chimney when all the gusts of wind and air temperature;

- The size of the combustion chamber, even if the calculated data is always the result of compromise and individual features corner fireplace. The more done, the size of the cross section of the furnace, better heating and worse traction. The smaller the depth camera, the more fumes and smoke can get into the room.

- Effectiveness also depends on proper size and position of chimney tooth. It is responsible for the absence of parasitic vortices emitted products of combustion and accumulated in the chimney soot in the opposite direction into the furnace and into the room.

Decor and cladding ↑

Almost always resort to the design of the appearance of plaster or special ink primer. In the latter case, it must be done mandatory to reduce the dust. Often, the tile veneer is used to close the crumbling outer surface of low-quality brick or defects in the masonry..

Instead of unnecessary decoration brick masonry treated with special solutions that destroy the efflorescence of lime, and painted with color enhancers. Even with the perfect decor corner fireplace as a heating element will draw on a hot surface large amounts of dust and vapors, therefore it is necessary to provide for the possibility of cleaning.