Fibreboard (MDF) construction sheet material, which is produced by drying of a wood fiber blanket or by hot pressing.

- wet – where it is not added a binder;

- dry, requiring the introduction of comminuted wood, synthetic resin.

Another name for hardboard is hardboard. Traditionally referred to as hardboard sheets hardboard low density. It is produced by the dry method of pressing of wood fibres with the addition of binders.

Distinguish between superhard, rigid, semi-rigid, insulation and finishing and insulating fibreboard.

The production of fiberboard or hardboard ↑

The manufacturing process of hardboard resembles the production of MDF. Here the raw material is waste and dust resulting from the processing of wood. These wastes undergo decomposition, and are then pressed using a special press. Thereafter, the resulting material dried. By weight of wood fiber is added to the emulsion, precipitators, special solution. Then the mass is fed to the casting machine, where slab is cast. This technology allows to obtain thin sheets.

Today, new technologies give the possibility to add new quality fiberboard. This expands their scope. In addition to the furniture industry and packaging production, currently there is a growing use of MDF in construction. It is very popular and gives the opportunity to improve the quality of work and significantly reduce the construction period and lowering their price.

Different types of fiberboard having different physical properties are used in the following types of work:

Soft fiberboard. Have a density of 150-350 kg/mThree, thickness 9 to 25 mm. Found application in construction as a material for insulation: roof, interior walls, coffered ceiling system.

Semi-solid fiberboard. Density 850 kg/mThree, thickness 6 to 12 mm. in Addition to the sheathing works of them make flush doors. In addition, they participate in the installation of ceiling slabs and making the coating under laminate.

Superhard fiberboard. The density reaches about 950 kg/mThree. Used in the device of coverings of floors of different purpose, fabrication of doors, temporary residential buildings, interior partitions. Water resistance of this Board gives a special impregnation.

Ennobled fiberboard (DVPO). Way laminated print on one of the parts of the plate to apply a variety of pictures and profiles. In the construction industry they are used as a design otlochno material for finishing ceilings and walls, devices, fireplaces, door and window openings.

Hardboard is easy to cut and handle. When working with this material there is no need to use special expensive tools and equipment. Among the latest novelties, in recent years, great popularity gaining arbolit is a wood-fiber plate, where the binder material is cement. These boards are used to construct partitions or in the form of building blocks. They are not subject to burning, free from releasing hazardous materials that have high strength to bending.

To improve moisture resistance and waterproof properties to MDF add rosin and paraffin wax. To protect the material from fire as additives used chemicals, called flame retardants. To resist bacteria allow antiseptic additive.

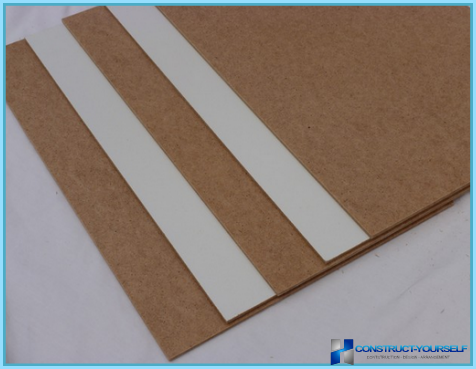

If, in addition to soak hardboard pactola, strength properties of hardboard noticeably increased. The front generally smooth surface and elevated staining, varnishing, plastic and decorative film.

The reverse side has a corrugated surface to achieve better adhesion with the adhesive material, however is also available double sided hardboard having a smooth surface on both sides.

Surface treatment ↑

Attractiveness add them using:

- laminating;

- lamination;

- coating;

- staining.

Laminating – the process of coating special decorative films roll type with glue. For lamination to a resinous impregnation of superimposed protective film.

The use of fiberboard ↑

The main sphere of use of fibreboard is a construction. Their production is subject to thorough control. All the parameters of the hardboard is subject to the requirements of GOST.

The use of MDF:

- the construction of wooden buildings (insulation of roofs);

- soundproofing of the radio studios and concert halls;

- the insulation space;

- manufacture of furniture;

- surfacing.

Marking the hardboard ↑

Hardboard is marked depending on such parameters as density, strength, view of the front surface:

- T – solid neoplagionotus;

- TS – solid face layer of fine wood pulp;

- TP is solid, the front layer is colored;

- TSP – solid front layer of fine pulp, which is colored;

- TV – solid with high water resistance;

- TSV – solid fine-dispersed mass, the increased water resistance;

- NT – solid, reduced density;

- ST – solid, high tensile strength;

- STS – solid, high-strength, the front layer of particulate mass.

Hardboard grades T, TC, TP, TSP level mechanical indicators are divided into quality groups: A and B, the quality of the plate surface is divided into grades I and II.

Sheet length up to 6 meters and width up to 2 meters. Most often used sizes 2140х1220 mm and 2750х1220мм.

Sheet thickness can be 2.5 mm; 3.2 mm; 4 mm; 5 mm; 6 mm and 7 mm.

When you purchase this material, you should pay attention to the labeling, and the ratio of price and quality.

To afford to buy hardboard and everyone can. Now you can buy them even online with delivery to the door.