The contents

Although metal — high-strength refractory material, the high temperatures devastating for him. It rapidly loses its strength, which is extremely dangerous for load-bearing structures and elements under constant load. Therefore, they need special protection, allowing to reduce or even to prevent the effect of high temperatures on the metal a certain period of time. This applies to fire-retardant paint for metal structures.

The types of flame retardants and their basis ↑

Fire-retardant paint varies according to the degree of protection, properties, and application features. There are two types of such coatings: intumescent and nevspuchivayuschiesya. The second option is costly and has a high popularity among consumers. Therefore, the most common type of such a coating is intumescent paint.

Intumescent paint intumescent also called. This name appeared thanks to three groups of reagents, which provide good protective properties of the material. Note three types of such substances:

- Nitrogen-containing reagents.

- Phosphorus acids and their derivatives.

- Polyhydric alcohols.

Each fire-resistant paint of this type is 40-60% of these materials. These components perform the functions of coating and when the temperature perform a gas-generation and on the basis of its composition create the coke layer to reduce the effect of high temperatures on metal.

Each component is responsible for its task in the passive period (in the form of paint), and fire protection. Although the principle of operation of the same colors, the composition may be somewhat different. Among the nitrogen-containing substances can be used melamine, Michelino or dicyandiamide. These components reduce the wear of the paint and also contribute to the formation of the protective layer and ensure its thermal stability.

Among the polyhydric alcohols used are the following substances:

- pentaerythritol

- dementedly

- starch

- dextrin

These polyols are the catalyst coking, contributing to the process of creating the protective layer. They also provide protection from fading and improve the adhesion of the substance.

The last type is phosphorus acid. They improve adhesion, improves the durability of the coating and its durability. But in case of fire, these substances significantly increase the rate and degree of expansion, preventing the smoke, the smoldering and burning. Among them melaminoformal, ammonium polyphosphate, esters and salts.

All these substances are the basis of fire-retardant paints. They contribute to the formation of a protective foam layer and prevent the heated metal structures. High quality fire resistant substances will keep the supporting structures of the building, with a particularly strong fires, protecting it from destruction. Therefore, they apply across the Board.

The work of the coatings at high temperatures ↑

Under normal conditions, fire-retardant paint is practically no different from usual. Although it has great strength and durability, the external differences are minimal. But her features begin to manifest when a high temperature.

Heat paint is a catalyst, starting the synthesis of porous oligomers, their formation and hardening. The speed of these processes and other characteristics of the coating depend on its composition, terms of use and temperature.

The process of emergence of a fire-retardant coating consists of several stages:

- The release of gaseous products. The protective layer in the form of gas contributes to subsequent reactions and prevents high temperatures on the immature coat of paint.

- The release of phosphoric acid. This triggers the synthesis of foundations for coke retardant foam.

- Destruction of the foaming agent. The temperature increase destroys a binding element that creates foam in the gas cushion, isolating the metal from temperatures.

- The decomposition of phosphorus compounds. This is the peak of reaction, foaming attributable to the temperature of 360°C.

- The pyrolysis of reticulated structures. Occurs at a temperature of 340-450°C. is Accompanied by violent foaming of the protective layer.

This creates an insulating cushion of coke with voids, filled with gas that protects the metal from heat.

The beginning of the reaction accounts for 250°C. This number is specially chosen, because at this stage there has been a rapid decline in properties of the metal and its strength. In the period from 250°C to 400°C, it gradually loses its quality, and then lends itself to minimal loads.

The duration of protection of a paint depends on the composition of the group. There is 7 groups, which prevent the action of fire on metal 15 (group 7), 150 minutes.

Popular brands of fire retardant paint ↑

Since the composition and quality of these paint products is very important, in the market there are favorites, whose products can be trusted with the protection of the supporting structure. There are several popular options, including:

- A THERMAL

Reliable paint manufacture over 20 years. Able to protect the metal during the period from 45 to 120 minutes. Offers several formulations which vary in price, properties, duration of protection and other parameters. - Vertex

Fire-retardant water-based paint is a reliable method of protecting metallic structures from high temperatures. The best part corresponds to the second group of flame retardants, which provides more than 120 minutes of continuous protection. However, there are other options from 3 to 6 groups. - Frizol

Fire-resistant coating Frizol corresponds to GOST R 53295-09 offers and compositions from 2 to 6 groups. The life of paint up to 25 years and high reliability in case of fire confirms the quality of this brand. - Joker

Water-soluble fire-retardant paint, the Joker is a good option for the protection of metal structures. However, it is better to use exclusively for applying in the premises, because it quickly loses its properties. 2-4 corresponds to the group of fire retardants, can be used outside if you are using finishing paint. - Vanguard

Fire-retardant paint avant-garde is the eponymous young company. This production won the recognition and high popularity as excellent protection from high temperatures. The ratio of quality and efficiency makes the vanguard a good choice for coating of metal structures. - Terme Suite

Production of Terma Suite offers a variety of compositions corresponding to 2-6 groups of fire resistance. Although the warranty period of operation covers only 15 years, the reliability of this structure is very high. Paint is applied only with positive temperatures, which is important to consider when purchasing.

- Krauz

Fire-retardant paint krauz offers a range of compositions corresponding to 3-6 protection group. This water-based coating applied in freezing temperatures. Paint krauz very effective against fire and can reliably protect the metal. - UGC 01

A fire-retardant paint, water-based with robust protection. It not only prevents the effects of temperature, but also suppresses the flames. Has a relatively high flow (more than 2.1 kg per square meter).

However, there are other popular options available in the market. They differ according to the used substances and their ratio, which significantly affects the characteristics of the coating.

The application of fire retardant paint ↑

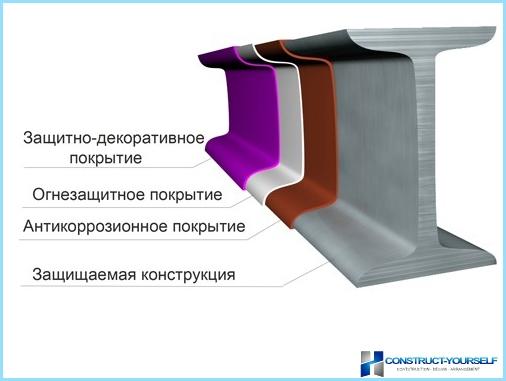

The quality of the application of flame retardant substances directly affects the degree of their effectiveness. It is therefore important to prepare the surface and create a durable layer which is not destroyed through time. To do this, perform the following steps:

- Surface preparation. The metal surface is thoroughly cleaned from various contaminants, corrosion, and mineral oil substances. Cleaning is carried out by mechanical or abrasive means. Before applying it is necessary to eliminate any dust and degrease the metal.

- Primer. Fire retardant paint should always go for a primer. The recommended primer GF-021, but other options are possible. The soil should be dry before applying the paint.

- Preparation of the paint. The composition should be mixed thoroughly with slow speed electric tool (with a mixer). After that wait about 20 minutes to eliminate air.

- Application. Coating it is recommended to apply by airless spray. For small areas you can use a brush. Roller is not recommended, it can reduce coating uniformity.

The coating is applied in several layers to increase the degree of protection. One layer is simply not enough to resist high temperatures. It is recommended to apply 2 to 5 layers to provide maximum protection from fire.

From the top you can apply a protective coating if the structure often is on the mind.

Fire retardant paint is an effective defense that can keep a building in case of fire. It will protect the metal components from fire, creating a foamy layer around them. There are many brands and formulations, but the effect of all similar. Therefore, you need to choose based on your own preferences and requirements.

For a better understanding of the action of such coatings, it is recommended to watch the video where the paint is exposed with a gas torch: