The contents

- The advantages and disadvantages of plaster Woodworm

- The variety of material for plaster

- The cost

- Technology applying plaster

- Instructions for applying the plaster “bark Beetle”

- Preparation of plaster

- Technology application

- Painting plastered surfaces

Many people in the final finish of the building prefer to use decorative plaster, but not everyone knows that this material is available not only for domestic but also for facade work. Each species differs from each other not only in terms of resistance to external environment, but also its structure.

For example, for interior finishing are the types of plaster that make the room more cozy and beautiful.

In turn, for facades it is recommended to use other types of material such as plaster «Woodworm». It is perfectly suitable for processing stone, concrete, plaster and masonry surfaces.

The advantages and disadvantages of plaster Woodworm ↑

One of the main advantages of this plaster is its high resistance to environmental influences. In the technology of applying plaster can last for years, easily withstanding extreme cold and heat.

Another advantage can be considered the cost of plaster “bark Beetle”, which is now quite acceptable compared to many other similar materials.

In addition, to finish the buildings on their own. Yes, at first glance, it may seem a bit difficult, but acquiring the necessary knowledge and right tools to cope with it even novice.

To the rest of the advantages are:

- High resistance to fire;

- Ecological purity of the material, as it is made only from natural ingredients;

- Light weight, allowing the construction of the building eliminates the additional load;

- Good resistance to sunlight, whereby the material retains its original color for a long time.

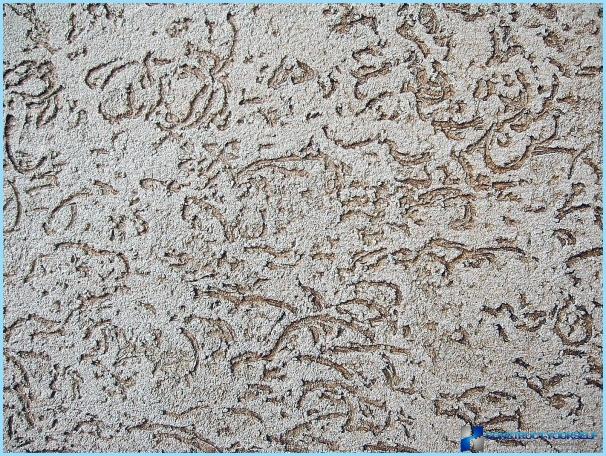

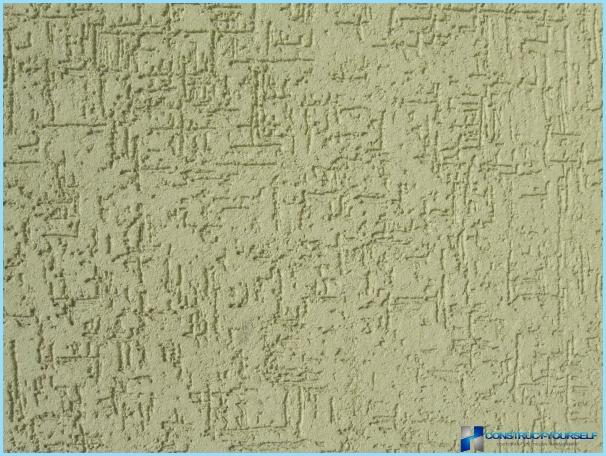

To the main disadvantage of plaster “Woodworm” refers to the complexity of her painting. The reason is the texture of the material, which after drying becomes like a moth bark beetle wood. Painting these grooves constitutes the greatest difficulty. The result was high quality and beautiful, will have to exert a lot of patience and effort.

The variety of material for plaster ↑

«Woodworm» made in two versions in acrylic and gypsum based. Naturally, between them there are some differences that must be considered when purchasing. For example, acrylic stucco has a more attractive appearance, which is achieved through sophisticated technology application (which will have to call professionals so as to achieve the desired result on its own is very problematic).

Acrylic «Woodworm» often sold in buckets, ready-made, which saves a lot of time. However, it is best to purchase the dry mixture. First, the cost of dry mortar less than ready. Second, it is applied to the work surface much easier. And, thirdly, the color of the final solution is a rather complex process, which requires the use of special machines.

The cost ↑

The cost «Bark» is about $ 15 for one bag, which is usually enough to finish 6-8 square meters. The cost of the services of a specialist who will carry out the decoration of the facade, in the range of $ 8-10 per square meter. Of course, you can master the technology application of this material, which will save a considerable part of the funds.

Technology applying plaster ↑

Decorative plaster «Woodworm» is a dry mixture of acrylic or plaster base, which contains fine granules of marble or mineral aggregate, and composite plaster. Grit plaster “Woodworm”, which affects the appearance of the facade, depends on the size of these granules.

Instructions for applying the plaster “bark Beetle” ↑

To perform work you will need the following tools:

- plastic grater;

- capacity for the preparation of the material;

- drill with a special nozzle with a mixer;

- metal spatula.

Finish facade plaster “Woodworm” includes four stages:

- preparation of the working surface;

- preparation of the solution;

- applying a mixture;

- tinting color.

Preparation of the working surface is one of the most important stages. For starters, the front surface is carefully leveled with cement-sand plaster. Plastering should be carried out to a pre-established lighthouse profiles established using the level. Their installation must be not less than 100-150 mm.

Between beacons throws cement-sand plaster, which further tighten the rule. If the tie remains, the defects, they were treated with a poluter or float. After about 3-4 hours the prepared surface and rubbed in a circular motion.

The next day, if need be, you can spend another grout. In that case, if the grout had to wear in the warm season, it is advisable to water it every day with water, to avoid cracking.

If necessary, this type of plaster can be used for facade finishing, insulated with foam polystyrene or Styrofoam. In this case, the surface of the insulation is required to pre-process adhesive, on top of which are placed reinforcing mesh.

Preparation of plaster ↑

After drying, cement-sand layer, you can start preparing the plaster “bark Beetle” and its application. At this stage special attention should be paid to the correct timing, after all, facing one wall need to have time to spend at one time (since joining the new site should be carried out with not yet dried the previous one). Through these actions, the working surface will have a smooth structure with no visible differences.

The process of preparing the plaster involves the following steps:

- first we need to take a clean container;

- then fill it with room temperature water in quantity specified on the package;

- then gradually pour the dry mixture while thoroughly stirring (to avoid lumps);

- after the mixture was drained, the solution continue to stir until then, until it becomes homogeneous;

- capacity then carefully closed for 10-15 minutes and then mix the solution again.

Technology application ↑

When using «Woodworm» for much more precise application is recommended to use a metal spatula. Perhaps the most difficult part of the work lies in the fact that complied with the required layer thickness corresponding to the grain size. In itself, the plastering is almost no different from putty is that the solution should stretch over the surface until, until you appear a small furrow.

To get the spiral texture on the fresh plaster light movement is carried out with a plastic trowel. It is worth to mention that, if the material is not dry, the result may not be too satisfied, but as soon as the plaster dries, it is significantly transformed.

Then again, the surface is polished with a plastic float, but stronger movements. During operation it is necessary to ensure that the plaster from sticking to the grater. In conclusion, carefully rubbing all joints.

Painting the plastered surface ↑

In most cases, facade plaster «Woodworm» available in two colours – white and grey. If you have the desire to give the material a different shade, during the preparation of the mixture should be added a special dye. In addition, the plastered surface can be painted with acrylic, latex or silicone paint.

In that case, if the dye is added to the plaster, one batch may differ from another in its color. To get rid of this not too easy, but if the wall surface is additionally colored paint, and don’t need. All batches simply must have the approximate shade, which can then be corrected.

The biggest challenge when painting decorative plaster is that paint must not fall into the furrow «Bark». For more accurate work, use a roller with a short NAP, which lightly pass over the entire surface texture. The result will be quite impressive.

In another method of painting «Bark» the color is added not in the plaster, and a latex or acrylic primer. Then primed treated working surface. Given that the primer itself is enough liquid it can easily penetrate into all the pores «Bark», carefully progresiva. As your drying, the primer forms a permanent layer. The result was a more attractive, apply the primer should be in two layers.

Manufacturers and price ↑

Among the most popular manufacturers of plaster «Woodworm», worth noting:

- Perfekta is one of the most economical options, the cost of which does not exceed 350 rubles per 25 kg of dry mixture;

- Bergauf DEKOR – price is about 450 rubles per compound bag;

- Ceresit is one of the most expensive options, the price is about 800 rubles per 25 kg.

For the treatment of 7-8 square meters requires about 25 kg (one bag) of dry mixture.

Buy facade plaster «Woodworm» can be in any hardware store or online site that deals in selling construction materials.