The contents

Monolithic reinforced concrete structures was first applied in Russia in 1802. As a material for the reinforcement were used metal rods. The first structure created using this technology was the Palace of Tsarskoye Selo.

Monolithic concrete structures are often used when manufacturing products such as:

- tanks,

- wall,

- ceiling,

- foundations.

Reinforced concrete monolithic construction allow us to construct buildings of any complexity and configuration. In addition, this technology is not limited to factory standards. The designer has an incredibly wide field for creativity.

Why do you need reinforcement? ↑

Of course, concrete has many advantages. He has great strength and calm during temperature changes. Even water and frost are unable to hurt him. However, its resistance to stretching is at a very low level. Here comes into play the fixture. It allows to achieve high strength and IMC to reduce the consumption of concrete.

In theory, as material for reinforcement you can use anything, even bamboo. In practice, used only two materials: composite and steel. In the first case — it is a set of materials. In the basis of the item may lie, basalt or carbon fibre. They are filled with polymer. Composite rebar has a low weight and does not corrode.

Steel has much more mechanical strength, besides its cost is relatively low. In the process of reinforcement of reinforced concrete monolithic constructions are used:

- corners,

- channels,

- I-beams,

- smooth and fluted rods.

When creating complex construction projects in the basis of monolithic reinforced concrete structures of stacked metal mesh.

Construction fittings can be of different shapes. But in the sale you can often find just the rod. The grooved steel rods are often used in the construction of low-rise buildings. Low price and good cohesion with concrete, which make them very attractive to potential buyers.

Steel rods used in the creation of reinforced concrete monolithic structures, in most cases, have a thickness of from 12 to 16 millimeters. They perfectly protect the structure from explosions. Load when compressed compensates for the concrete itself.

Features reinforcement depending on the type of Foundation ↑

When the Foundation is laid at home it is very important to follow the rules of reinforcement a monolithic reinforced concrete structures. This will avoid a variety of defects and guarantees the long term operation of the facility. According to the construction of reinforced concrete monolithic structures there are three types of Foundation.

Slab Foundation ↑

When reinforcement is used the core corrugated fittings. The thickness of the concrete monolithic construction (plate Foundation) depends on the number of floors and material used in the construction. Standard rate 15 and 30 centimetres.

Qualitative reinforcement of the slab Foundation should have two layers. The upper and lower grids connected by props. They form a gap of desired size.

The main difference between the professional reinforcement of reinforced concrete monolithic structures — is the complete concealment of all elements of the steel frame. At the same time in tile the Foundation rebar is not welded together, and fit through the wire.

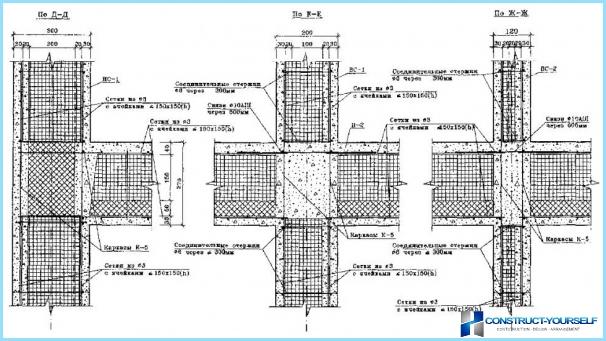

Strip Foundation ↑

The device of this reinforced concrete monolithic construction consists of a grid, which is placed at the top and takes all the load associated with the tension.

Welding the frame elements is not recommended — this will reduce its strength. The concrete layer that separates the steel elements and the soil must be at least five centimeters. This will protect the metal from corrosion.

In monolithic reinforced concrete structures is very important to observe the correct distance between the longitudinal rods. The boundary indicator is 400 millimeters. Cross members are used when the height of the frame is more than 150 mm.

The distance between adjacent rods in reinforced concrete monolithic construction may not exceed 25 millimeters. Corners and junctions are further amplified. This allows you to give the Foundation greater strength.

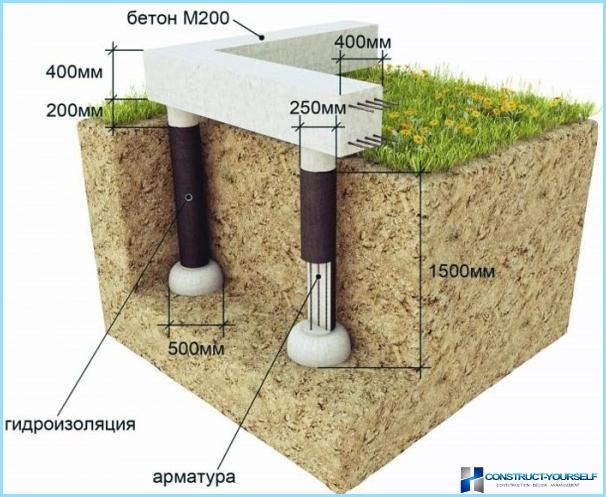

Pile Foundation ↑

This technology is used during the construction of constructions on heaving soils. The optimal distance from the grillage to the soil of 100-200 mm. the Gap allows you to create a cushion of air, which positively affects weplanet of the house. Besides, the air cushion allows to avoid the formation on the ground floor damp.

When creating piles used concrete grade M300 and above. Pre-drilled wells, which is embedded in the roofing material. It also serves as a formwork. The framework of reinforcement is lowered into each hole.

The design of the frame consists of a longitudinal grooved reinforcement. The cross section of the rods 12 to 14 mm. the Attachment is through a wire. The minimum pile diameter — 250 mm.

The walls and floors ↑

These elements also require special rules reinforcement. In principle they are similar to the rules of foundations, but there are some differences:

- The minimum longitudinal reinforcement bar diameters in the wall — 8 mm, the maximum step length 20 cm, cross — Section 35 cm transverse reinforcement of not less than 25% of the cross-section of the longitudinal.

- Ceiling. The diameter of the rebar is determined by the design loads. The minimum rate of eight millimeters. Distance between bars of not more than 20 mm.

- The walls and ceilings allowed the use of a grid.

Rules of reinforcement for walls and floors differ due to different degrees of loads experienced by these reinforced concrete monolithic construction.

The main rule reinforcement ↑

The strength of the whole reinforced concrete design depends on the communication of concrete and reinforcement. You want the concrete to transfer part of the load of the steel reinforcement without the loss of energy.

The main rule of reinforcement says that in reinforced concrete construction should not be disrupting communications. The maximum value for this parameter is 0.12 mm. Reliable connection of concrete and reinforcement is a guarantee of strength and durability of the entire building.

Design ↑

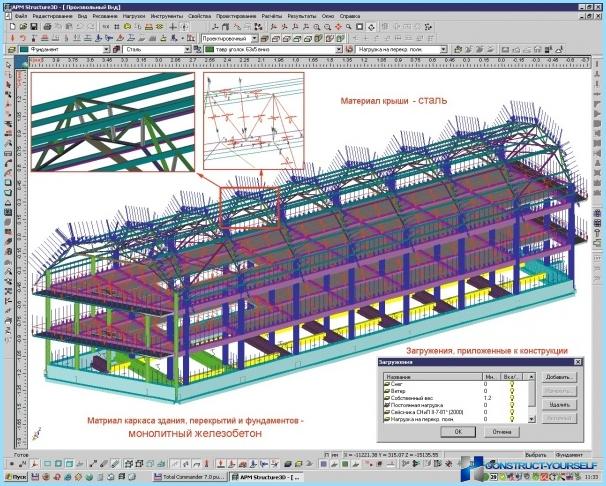

What is a design? ↑

Design of reinforced concrete monolithic structures is to create drawings based on collected survey data, available materials and purpose of the building. Bearing system of the monolithic frame of the building up of the floors, foundations and columns.

The task of the designer to calculate the load on all elements and to make the best project taking into account peculiarities of soil and climatic conditions. The process of creating reinforced concrete monolithic structures includes:

- layout;

- the calculation of the design of the secondary beam;

- calculation of loads;

- calculation of beams limit States of the first and second groups.

To simplify mathematical calculations, a special software is used, for example, AutoCAD.

Design and calculation according to SNiP ↑

In fact the manual for design of monolithic reinforced concrete structures — this is a SNiP. This is a set of rules and standards that contains standards for the construction of residential and non-residential buildings on the territory of the Russian Federation. This document is updated dynamically depending on changes of construction technology and approaches to safety.

SP on monolithic reinforced concrete structures was developed by leading scientists and engineers. SNiP 52-103-2007 for IMC, made on the basis of heavy concrete without prestressing. According to this document there are the following types of supporting elements:

- column,

- wall,

- column-wall.

When reinforced concrete monolithic structures allowed the design of floors in different constructive system of load-bearing elements.

When calculating the parameters of bearing elements according to SNiP is taken into account:

- The definition of effort, acting on the Foundation, floors and other design elements.

- The amplitude of vibration of the slabs of the upper floors.

- The calculation of the stability.

- Evaluation of the resistance to process of destruction and bearing capacity of the building.

This analysis allows not only to define the parameters of monolithic concrete structures, and also check the life of a building.

Special attention is paid to the design of the bearing reinforced concrete monolithic construction. This takes into account the following parameters:

- The ability and speed of cracking.

- Temperature-shrinkage deformation of concrete during solidification.

- The strength of the IMC when removing the formwork.

If the right to make all calculations, the generated product will last for decades even in the most extreme conditions.

When calculated carrier parameters were established using linear and non-linear stiffness of concrete elements. Second prescribed for continuous elastic bodies. non-linear stiffness is calculated in a cross section. It is very important take into account the possibility of cracking and other deformations.

The order of execution of the construction works with IMC ↑

Every construction company is trying to achieve a better organization of the production process. For this purpose Snips and international standards. However, there is an established procedure that ensures the maximum quality of the future building:

- First, the calculations are carried out along four main types of loads: permanent, temporary, short-term, special. For example, when creating the Foundation for the units that generate strong vibration, is used exclusively reinforced concrete monolithic construction.

- Geophysical exploration, planning, and analysis of common indicators.

- Determining an erected structure.

- Reinforcement structures. It is of two types: pre-stressed and conventional.

- Installation of the formwork. Formwork allows you to create the necessary form for the future concrete structures. While it can be classified as razmernosti, material, purpose and design.

- The concreting. There are four main ways of pouring concrete with a pan mixer directly into the formwork through concrete pump; through the chute, with the help of a bell. To seal the concrete use a vibrator.

A very important part in the creation of a durable and reliable reinforced concrete monolithic construction plays a care concrete. The fact is that this material can harden only under certain conditions. Usually full hardening of concrete takes about 15-28 days, if you do not use special varieties of cement. To prevent evaporation during the hottest time of the year IMC watered.

How is the installation? ↑

This technology allows to save on materials, because the developer determines the feasibility of the use of certain design elements. Installation of reinforced concrete monolithic structures takes place directly on the construction site and consists of the following stages:

- To the site fit material for reinforcement. It is important to comply with regulatory distance between the frame elements. This ensures uniform spreading of concrete.

- Concrete will be poured. At this stage, care must be taken that the mixture does not fell oily substances. They prevent the binding of concrete.

- If necessary, additional equipment has been installed to speed up drying.

Reinforced concrete monolithic construction allow to create curves, making the overall architecture of the building is a lot richer and richer.

The results ↑

Reinforced concrete monolithic construction allow to build buildings in the shortest time using modern varieties of concrete. An important step in the construction is the design. The correct calculations allow you to create a solid construction with long life.

Reinforced concrete monolithic construction used in the construction industry, and housing. Relatively low cost and durability make them indispensable in the production halls and in the construction of multi-storey buildings.