The contents

- Prefabricated concrete structures

- Monolithic reinforced concrete structures

- Precast-monolithic reinforced concrete structures

Concrete structures have become a real breakthrough in the 19th century. Now almost all construction objects are being built with their help. At the moment, every day the world produces two billion cubic meters of concrete. Without them, an impossible construction of offices, high-rise buildings and industrial buildings.

Concrete structures allow quickly and with minimal cost to build houses of different degree of complexity. Inherently concrete is rebar filled with cement mortar.

Characteristics of concrete ↑

Concrete has great strength. This allows you to build buildings with a long life. Besides, he is well resistant to changes in temperature. Other useful characteristics of this material is referred:

- frost,

- high density,

- water resistant,

- fire.

The strength of concrete in compression is 10-20 times greater than in tension. This parameter depends on the sand and gravel. The main role is played by the quality of the cement. It is the cement determines how stable the composition.

The casting of the concrete can protect the reinforcement from corrosion. Buildings made from this material are durable and durability. Very much on the quality of the material affects the porosity, namely, the ratio of pores to the total volume.

Density is the ratio mass of concrete to its volume. The higher this characteristic, the more durable will be the concrete structure. Due to the high density of concrete resists the compression.

Regardless of the thickness of the concrete structure, it could effectively transmit the heat flux. The thermal conductivity of the concrete is 50 times less than steel, but much higher than that of brick.

The result of the low thermal conductivity of reinforced concrete structures is their resistance to fire. This material is also used in the regeneration of industrial buildings where it is necessary to work with high temperatures.

An important characteristic of concrete is its frost resistance. This material when saturated with water can withstand repeated temperature changes without any consequences. The percentage of strength reduction is minimal.

However, concrete has a significant drawback. Its tensile strength is extremely small. Therefore, in the design of reinforced elements are added. For example, steel wire or rods.

A single reinforced concrete structure has high strength and good tensile strength. Besides, the technology of creating these products for the last 150 years has changed dramatically and continues to improve every day.

What is the reinforcement? ↑

Reinforcement allows you to create concrete structures for centuries.

The best example in this context would be the construction of strong and durable floor. In the process, is the coupler on the metal base. The concrete floor is of the following types:

- liquid;

- resting on the ground or plate;

- screed with a layer of insulation;

- the coupler is based on slabs.

Besides increasing the strength of the concrete structure, the reinforcement can reduce the cost of concrete. In the process, can be used such materials as:

- reinforcement cage,

- fiberglass mesh,

- a grid of wire rod,

- welded wire mesh with cells,

- a grid of polymers,

- fibro.

A wide selection allows you to choose the best option for creating high-quality and durable reinforced concrete structures.

The types of concrete structures ↑

Reinforced concrete can be classified in many ways. Over 150 years of continuous improvement has been invented many methods of creating reinforced concrete structures with the use of different technologies and varieties of concrete.

Prefabricated concrete structures ↑

They are produced at the construction site of the pre-prepared items. In this FLC are created by specialized companies, where there is the necessary equipment and high level of automation. This allows you to reduce costs and maximum productivity.

At the time, the creation of FLC extremely positive impact on General industrialization and mechanization of the construction sector. Precast concrete construction allows to erect buildings in any weather conditions. You can build a in winter and summer, in rain, wind and heat.

Nevertheless, prefabricated concrete structures have one major drawback, namely the high complexity. In addition, the creation of joints has a greater metal content and the corresponding cost.

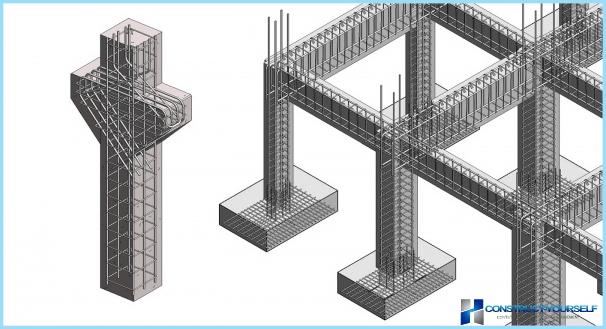

Monolithic reinforced concrete structures ↑

These products are created directly on the construction site by concrete in the formwork. As a result of reducing the cost of the SWC can be achieved by reducing costs for concrete, rebar, formwork materials and labor.

The developer shall determine the validity of the use of a number of materials depending on the complexity of the object and its purpose. This allows you to create a more flexible estimate, realistically assessing the needs of the production.

The main advantage of monolithic reinforced concrete structures is their spatial integrity. If you take the professional terminology, it is a high static uncertainty. Due to this monolithic designs have low consumption of materials.

SWC use as for the construction of typical and unique buildings. These products allow you to build objects using different types of formwork, including:

- fixed,

- mobile,

- billboards,

- block.

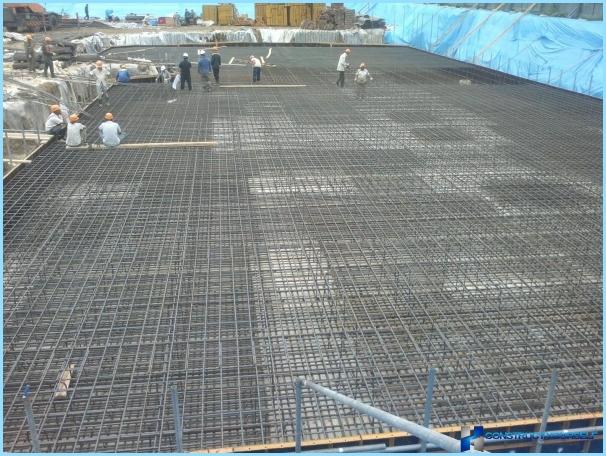

When you create a monolithic reinforced concrete structures are applied to large blocks of rebar and reinforced spatial frames. This technology also allows to establish a mechanized supply and laying of concrete. There are a number of structures that are only created with the help of the MRC, these include:

- pools,

- foundations,

- powerful structures with dynamic loads.

In each of the above embodiments, the use of monolithic reinforced concrete structures economically. Despite major benefits, this technology has its drawbacks, among which:

- time-consuming formwork;

- the seasonality of work;

- construction time depends largely on the speed of solidification of the mixture.

Work with monolithic reinforced concrete structures is carried out only during the warmer time of the year. To speed up the process use a special type of cement that hardens very quickly.

Precast-monolithic reinforced concrete structures ↑

It is a set of elements. According to this technology of precast and monolithic reinforced concrete fit together.

The main role of this technology is the quality of the bonding precast elements in-situ. To achieve the desired result of modular designs can have different shape and size. In systems of this kind can be used stressed and non-stressed reinforcement. All depends on the situation and purpose of the object.

If the surface of precast concrete structures has a high level of roughness, it is possible to dispense with dowels. In places where the prefabricated elements are in contact with concrete, provides for release of the transverse reinforcement. Anchoring is placed in the monolithic concrete further.

Precast-monolithic reinforced concrete structure combine the advantages of both previous types. They are very economical and allow you to build buildings using modern methods quickly and efficiently.

In the monolithic elements are widely used are lightweight and cellular concrete. Allowed the use of artificial porous aggregates. Which significantly reduced the weight of the design.

The rules for creating a robust reinforced concrete structures ↑

In the process, must be complied with all building codes and standards of construction. Some organizations are additionally focused on the international standards to gain an important competitive advantage. However, there are a set of binding rules that must be followed when creating the concrete slabs:

- Mesh or frame should not create obstacles to the uniform distribution of concrete.

- First on the pad fits material for reinforcement and only after that is fill.

- You must avoid falling into the concrete structure of oily substances. They prevent the formation of strong bond between the concrete and the frame.

- To protect reinforced concrete from corrosion, the concrete should completely hide the reinforcement elements.

Frame reinforcement is used when the Foundation and floors — single lock at home. Similar technology is used in construction on soils with low degree of reliability.

The results ↑

Used in modern construction all types of concrete structures depending on their particular benefits. The most important is the observance of all rules and the construction standards that ensure the safety and durability of construction.