The concrete slab has gained huge popularity almost immediately after entering the market. In contrast to the archaic hardwood floors they are many times safer and have such advantages as:

- refractoriness,

- moisture,

- long life.

Concrete slabs do not rot and can save all its properties at high temperatures and humidity. It is an ideal material for the construction of industrial and housing objects.

Concrete slab at the time, changed the canons of construction. Their low cost and high performance made a splash on the market. Because of this, many construction companies were forced to leave their businesses or to shift.

A real shock for builders and designers was the length of one concrete slab, which reached seven and a half meters. It changed the very essence of architecture. The result was not only new buildings, but technologies for their rapid construction.

The types of concrete slabs ↑

Road concrete slab ↑

This technology made possible the creation of complex traffic intersections. No highway or highway is not complete without these structural elements.

Road concrete slab retain their performance properties even at temperatures to -40 degrees Celsius. The use of these products in the construction of roads allows to significantly increase the reliability of the entire canvas.

These products are available in two versions: with stressed and non-stressed reinforcement. The average density of concrete is 2200-2500 kg/mThree. Road reinforced concrete slabs can withstand the load of a class N-30 and N-10.

The surface has a special corrugation. When creating a design applied concrete waterproofing and frost resistance F200 meets the parameters and W4.

Special mention deserve the airfield concrete slabs. They are able to withstand high loads. When creating this design uses a reinforced frame and concrete below grade М350.

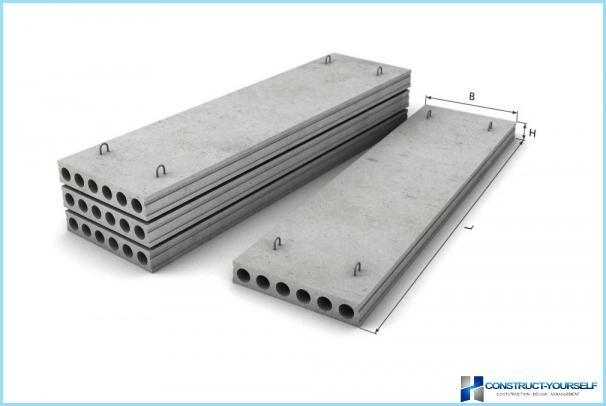

Hollow-core concrete slabs ↑

PBP are used in the construction of the floors. The thickness of a single article 220 mm, length from fifteen to sixteen meters. Standard width can be 1, to 1.2 to 1.5 meters. Also it is possible to select individual parameters.

Voids in reinforced concrete slabs provide thermal and acoustic insulation. Holes can be either round or oval. The presence of voids in construction greatly facilitates the weight that affects the speed of installation and the overall structure of the building.

Modern technologies allow to produce large quantities in a short time. The load on a reinforced concrete slab can reach 1250 kg/mTwo. In the process of production is used for concrete of different grades.

Flat concrete slab ↑

PBP are the backbone of slabs in prefabricated buildings. In this case the calculated load shall not exceed 6 kPa. Reinforced concrete flat plate can withstand seismic shock force of up to 7 balls. They are mounted on load-bearing structures with two, three and four points of support.

The main material from which manufactured products, is heavy, medium and light density concrete. It uses stressed and non-stressed reinforcement. Also allowed the use of wire of VR-1. All structural elements shall meet the Standards.

The edges are flat concrete slabs can have bevels. They serve to connect products with each other. Also, this structural feature prevents shifts. The joints between poured concrete PBP solution.

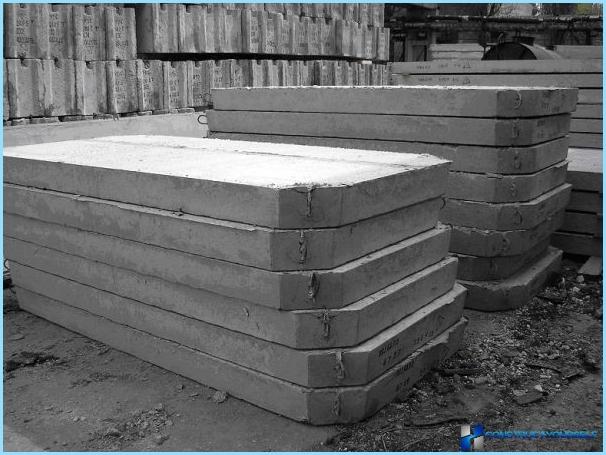

PBP are transported in stacks. That products in transit are not damaged, use special pads, providing a gap between concrete slabs.

In the body of the car flat reinforced concrete slabs stacked longitudinal axis in the direction of in the direction of motion. Unloading and loading is carried out using a crane. Special mounting hinges greatly accelerate this process.

Concrete slab ↑

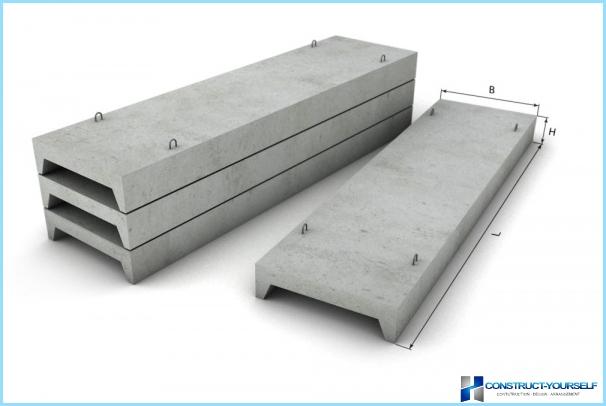

These products are used when it is necessary to complete the construction. Often such a need arises in industrial buildings, where the builders do not want to spend extra money to install a full attic.

In the future, this roof is covered with a special finishing material. Most often it is the bitumen or liquid rubber. These substances provide excellent waterproofing, and the cost is low.

Reinforced concrete panels perfectly match with thermal insulation materials. In addition, the installation of sewers and other utility systems does not take much time and effort. Products are divided into two types depending on installation methods: standard and ribbed.

Construction with a ribbed surface to make the roof more durable. Also, this form greatly simplifies the process finishes. In production often involved a tense fixture. She ensures durability.

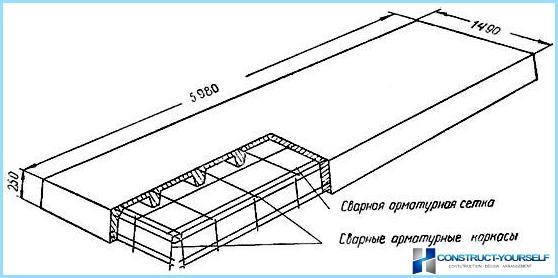

A big role plays in the design of reinforced metal mesh. It is covered with a concrete layer of 2 cm, It protects the rebar from the hostile external environment.

Concrete floor slabs have a high level of fire safety. Some modifications can withstand loads up to 1500 kg/mTwo. These products are used in areas with high rainfall. Moreover, this strength gives you the ability to build some more floors.

Usually in the construction process use of concrete slab 2X12 and 3X6. But of course, exceptions are possible. Sometimes the factories are special modifications for specific tasks.

The thickness of the products ranges from 250 to 455 mm. But there are thicker options. Increasing thickness gives decreasing weight, respectively, minimizes the load on the supporting structures.

In the structure of reinforced concrete slabs would be impossible without embedded elements. They are made of steel and can be welded with fittings adjacent products. This ensures a solid connection.

Products are transported on special trucks and are used at the end of the construction works. They are suitable for virtually any type of construction and possess high durability and reliability.

The production of concrete slabs ↑

The main element of reinforced concrete slabs is the concrete. This material is made by mixing cement with sand and gravel. It has high resistance to compression, but is easily stretchable. To increase the strength of the material, used fittings. It is made of composite and steel.

The gravel acts as an inert material. Between it and the cement it does not react. It is also called a placeholder. It greatly influences the structure of reinforced concrete slab.

In the production of concrete slabs using crushed stone of different fractions and from small to large. The choice largely depends on the purpose of the design and requirements facing the designer.

Reinforcement is of two types: working and installation. The first type is a bottom part of concrete slabs. It works in bending. The second is the skeleton of the design.

In the process of making concrete slabs used stressed concrete. Special technology allows to pour rebar in concrete, when it is in partially strained form. This is done due to the fact that concrete slabs should be efficient to resist bending and to compensate for the load of the floor construction and the weight of extra items on it.

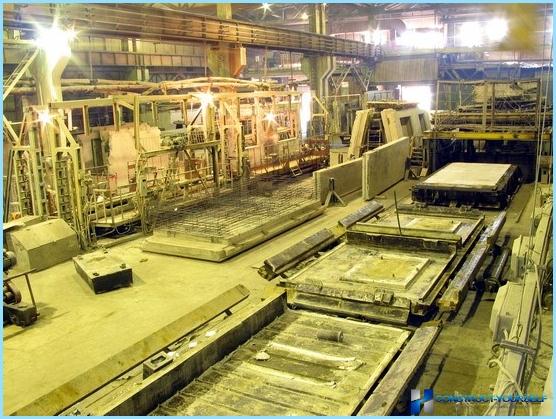

The technological process ↑

It all starts with creating a preliminary drawing. On its basis future products. Usually, the whole process consists of these stages:

- In a specially prepared form sets the frame of the armature. Typically, this use of ribbed bars. They are pre-bent using heating or electric Jack.

- The rods are fixed on boresnake forms.

- Further, the production process is carried out based on the conveying line, special stands, roller molding or rental.

- After the formation of the main structure of reinforced concrete slab is sent to the heat treatment. For this purpose, a special camera. Thermal processing allows to greatly increase the speed of hardening of the concrete mass. For 10 hours the product is gaining about 60 percent strength. Usually it takes at least 25 days in normal conditions.

- Once the product has gained the necessary strength clean mounting on the walls of the mold, fixed by the reinforcing bars.

- The rods shrink in length. The result is a necessary condition of the whole structure.

This is a canonical production process of a reinforced concrete slab. But many companies are trying to bring in something different to achieve higher performance and reduce the cost.

Rules of installation of concrete slabs ↑

During laying of slabs the builders first focused on building codes. Compliance with all regulations and standards to ensure safety and long life design.

Reinforced concrete slabs are placed on the walls of the building. They must rely on the bearing wall by at least 12 inches. Products can be placed with use of the solution and without it. The size of the technological seam ranges from 5 to 20 cm in the Perfect setting of 7-8 centimeters. If the seam is too wide, then later have to spend a lot of time and solution termination.

Of course, the rules of stacking, for example, concrete road slabs are very different from the rules of the installation cavity. But the initial stage is the same in both cases. Before installing the plate is thoroughly inspected. If a marking on each design. If there are cracks wider than 1 mm on entire length of the concrete slab is replaced.

The results ↑

Depending on the type of design and its purpose, the builders used some kind of concrete slabs. There is a huge number of modifications and types, designed to suit a certain construction.