The contents

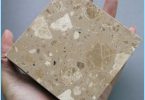

Concrete is the main material of modern construction, prepared according to special technology. The introduction of additional ingredients in this material contributes to the improvement of its technical and structural parameters.

On the classification ↑

The concrete used in modern construction, are divided by six major characteristics:

- purpose;

- the average density;

- varieties of binder;

- frost resistance;

- strength;

- waterproof.

Silicon material, its main purpose, has the following classification:

- special;

- structural.

You can also divide the variety of silicate filler on concrete:

- materials having tensile strength under compression along the axis in the range of 7.5 – 70;

- materials having tensile strength tensile axis in the range of 1 to 4;

- materials having tensile strength in bending in the range of 2.5 – 7;

- with water resistance in the range of 2 – 10;

- with an average density of 1000-2400 kg per cubic meter.

According to its properties this material is similar to the products made of cement composition.

The technology of preparation ↑

Modern production of silicate concrete involves the use of various binding materials:

- lime – silica, consisting of finely ground quartz sand and lime;

- the slag, which contain lime, iron and steel, phosphorus, or fuel slag;

- lime – ash, and includes fuel ash and ground limestone;

- lime – believe where mixed sand, believei sludge, lime – siliceous mixture

To prepare the silicon-containing concrete, the following are required:

- binder;

- fillers;

- water;

- special additives.

Quality blocks of sand-lime concrete is popular because they are able inside the room to maintain optimal microclimate, accumulate heat in the case of higher humidity, absorb excess water vapor.

The advantages of limestone blocks ↑

The advantages of blocks include:

- the resistance to cycles of cold (rated at 50 – 100 cycles);

- excellent sound insulation characteristics;

- temperature resistance;

- a long operational period.

In the framework of the state program «Affordable housing», production budget of silicate products of the material non-autoclaved and autoclaved become a promising direction. Sandy – clay rocks with good chemical activity, used for production of silicate autoclave concrete. In the process of autoclave processing of such material on accelerated version of the hardening receive coarse phase of different composition. They play the role of fillers for low-basic hydrosilicates, which get when mixing sand, lime and clay.

During the solidification of the binder in the material is formed of high-strength artificial stone. Component silica (crushed sand) affect the structure of the material. With the increased dispersion of the sand grains increased and operating characteristics of the finished composition:

- frost resistance;

- strength.

The siliceous component is natural or artificial pozzolan: fine quartz sand, blast furnace metallurgical slag, ash CHP.

The result of the reaction between sand and lime, occurring in the autoclave, will be a low-basic calcium hydrosilicates possessing scaly or tonkomolotye microcrystalline structure, increases the resistance of products.

Basic operations when you create silikatobetonnye materials ↑

When you create silikatobetonnye materials is carried out in the following order:

- mining of sand, the release of a coarse fraction;

- limestone, its heat burning;

- crushing of lime;

- mixing lime, sand, plaster, grinding in a ball mill;

- the mixture preparation. In the mixer with forced stirring to the lime, sand, add water;

- the formation of the specified products;

- the hardening in the autoclave molded parts in the temperature range 174 – 200 ° C, pressure 0.8 – 1.5 MPa. If you want to make a dense product, are lime, having a specific surface area of 5000 cm2/g, the sand with the index of 4000 cm 2/g;

- cooling the product in an autoclave or out of autoclave.

What determines the quality of the products ↑

Quality autoclaved sand-lime parts depends not only on the structure and composition of supplements, but the proper control of physical phenomena that occur at different stages of processing the mixture in the autoclave.

For three-dimensional mass of silicate concretes are divided into:

- silicate heavy concretes, which fillers are gravel, sand, crushed stone;

- silicate lightweight concrete, with filler acts as expanded clay, vermiculite;

- silicate cellular concrete, as a filler are air bubbles distributed uniformly throughout the volume of the product.

Forming large-sized products is performed directly at the construction site, durability of such products (on a break) up to 60 MPa.

The main application ↑

Silicate concrete is a rare type of concrete, rarely used in ordinary construction.

Silicate concretes are a group of cement-free concrete that get when mixing sand – lime, fly ash – lime and siliceous and calcareous binders components.

- The maximum value has a cellular silicate concrete that is filled with evenly spaced air cells or bubbles. Such material has excellent insulating properties.

- Dense silicate concrete – Foundation for the manufacture of structures in industrial, residential, rural construction: floor slabs and interior walls; beams of ladder platforms and marches; curtain panels; columns and beams

- Heavy concrete is used currently to create a compressed non-asbestos slate, the stress of reinforced concrete – silicate railway sleepers, the manufacture of reinforced silikatobetonnye railway sleepers.

- Autoclave dense silicate concrete used for the manufacture of load-bearing panels for internal walls, creating floor slabs.

- Dense silicate concrete used to create the Foundation of highways, the construction of mines.

- Silicate material on porous fillers – a new kind of concrete. Used to create porous aggregates: expanded perlite, expanded clay, slag pumice.

In low-rise construction you can apply this material for the following purposes:

- elements of non-removable iron – silicate formwork for the creation of strip Foundation;

- to make fundamental blocks;

- make the blocks for basement walls;

- to create staircases and steps;

- to manufacture shingles;

- draw the linear elements of the truss system; to create tiled roof sheathing.