The concrete ring has found wide application in all fields of construction. Most often they are used to create water wells and septic tanks. These products have high strength, frost resistance and fire resistance. Therefore, they are used in such complex structures as the gas network.

Concrete rings are used to create drainage systems. The main purpose of building such a well is the reduction of groundwater level. Rebar, used to reinforce the structure, can effectively resist stretching. Concrete, in turn, assumes the entire load of compression.

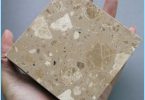

In the production of concrete rings are used different grades of rebar and cement. In most cases, it’s the bars of ribbed form, round in cross section. The concrete in this case performs a protective function by not allowing corrosion to eat away at the metal.

The LCD is not used in the construction of underground horizontal piping. This is due to the impracticality of these systems. Low airtightness leads to leaks and appropriateness of these elements disappears.

General information ↑

The types of rings, their specifications and testing of finished products ↑

Depending on the application and properties of the concrete ring is divided into the following types:

- water,

- gas,

- sewer.

There are also special modifications designed to narrow the scope of use. Diameter of products ranges from seventy to two hundred millimeters. The average height of about fifty centimeters. The highest reinforced concrete rings can reach two meters.

Before to go to the construction site or in the sale of concrete rings must undergo special testing. To do this, the party takes one or two instance, and with them conducted a series of tests, usually tested the following parameters:

- water resistant,

- frost,

- water absorption.

Sometimes in the process of testing some of the concrete ring are destroyed specifically, to determine the limit load factor. Modern technologies allow to avoid it. The ultrasonic method gives the possibility to check the option to compact the concrete without catastrophic consequences.

How to produce the LCD? ↑

At the initial stage, the designer creates the project, specifying the exact parameters of the product, then come the following:

- The preparation of the concrete mixture. For this purpose, cement M400. It provides perfect grip and high durability. To increase the plasticity of the design added to the mixture of special plasticizers. Gravel added to the mixture should have a fraction not larger than 20 mm. of Course, without the sand and water do not work.

- The concrete mixture is stirred in a mixer to the desired condition.

- Concrete is poured into the form. The valves, placed there in advance.

- At the end fill in the form inserted securing postobituary.

- With the help of the machine is compaction and compaction.

- Rotary beam removes the top of the concrete ring.

At the end of the installed outer casing. This is done on level ground. The duration of hardening of seven days.

Concrete rings with their hands ↑

Of course — to buy concrete rings in the factory easier. But the question immediately arises of delivery. LCD is large-sized products, delivery of which requires special transport. The lack of proper road to the place of construction work often puts an end to the possibility of building the well.

But there is a solution. The concrete ring can be done by hand. Of course, this will take time and will require some skills, but to repeat the whole process in home real. Besides, if you have all the necessary materials, such a decision will save a lot of money.

First you have to decide what the concrete ring you need. Take a piece of paper and draw a future design. Specify the height, thickness and diameter.

You can buy ready-made mold or make it yourself. For this you will need two metal barrels, corresponding to the diameter of the desired concrete ring. If the walls of the barrels is stamped ribs — nothing. They are not povelivaet on the performance of future products.

If in the household of barrels, you can use a pipe or make the formwork from metal sheets. Plastic drums are also well suited to this task.

After a half-timbering found, you need to make two longitudinal marking of the external side of the concrete ring. They need to split the mould in two equal parts. Next you need to produce the following:

- Lines installed window or door awnings that are attached with rivets. You can also use welding.

- On the internal lines of concrete rings to create a projection of the external lines.

- Using the grinder cylinder is cut inside the lines. While cutting the circle should be the thinnest of all.

- On one side of the sheds cut off the cap-locks.

- Cut the spindle to be withdrawn.

In the process of creating formwork a lot of attention should be paid to the inner cylinder. In many respects, its quality affect the operational characteristics of precast concrete rings. The creation process consists of the following stages:

- On the inner side of the cylinder are applied for two horizontal lines. The distance between them must be 1/3 of the circumference of the casing. In the end, one part get bigger than the other by about two times.

- On the inner side where there is a markup, set sheds.

- Creates a projection of the internal lines to the outside.

- The cylinder is cut along the lines made previously.

- Cut off the heads of the spindles.

Once assembled, the inner cylinder must rise above the outer 5-10 cm of the Outer form should be easy to open and close. When the concrete ring is released in the first place removed the inner form. Cleaned the spindles, and the cylinder extracted from fresh concrete rings.

The technology of manufacture of precast concrete rings ↑

When the ring is made of reinforced concrete, the ambient temperature should not be below 8 degrees Celsius. In very hot weather need to take care of extra moisture. In the process, allowed the use of cement grade not lower than the M400. The technology includes the following steps:

- Preparation of cement mortar the right consistency. The ratio of cement to sand 1/3. Also don’t forget to add in the mixture the gravel fraction is not more than 20 mm It should not be many, about one in five of the total weight.

- The mould is placed on a level floor. The pan must be metal or wooden.

- Between the inner and outer cylinder is laid reinforcement mesh. Alternatively you can use plain wire. It fits the loops together with the addition of concrete.

- Below the cylinders are not moved during concrete placing, are set restrictive wooden wedges.

- Fit the solution around the entire circumference to a height of about 20 centimeters.

- Compacted mixture with a metal pin.

- Laid another layer of concrete.

- The wedges are removed when the sweep level will rise above the average.

- After the concrete is laid, the top is leveled.

Formwork is removed in 4 days. To achieve the design desired strength required 7 days. During this period you need to make sure that the concrete doesn’t dry out.

LCD for wells ↑

Despite the large distribution of wells, the wells still do not lose their relevance. This is due to such factors:

- the relative cheapness of construction;

- uninterrupted supply of water;

- long service life;

- easy to use.

Often during installation of the wells with drinking water used reinforced concrete rings with a lock. They are closely attached to each other, and thus the possibility of leakage is reduced to almost zero.

An important role in the construction of the well wins back pillow and stand — a kind of Foundation, not giving the building to sink. The lock on the rings allows you to effortlessly install the last reinforced structure frame for manual water flow.

LCD for sewer ↑

Due to its practicality, durability, and relatively low prices, concrete rings are often used when creating Sewerage systems in country houses. The process is not very complex, so having the basic skills of the Builder, everyone can cope with the construction of a septic tank in his yard.

In the process of creating a septic tank apply the following types of rings:

- With interlocks. In the upper part of the concrete ring has a special protrusion and the lower recess. In the process of assembling one ring onto another, thus creating a solid construction. During operation of the structure is not shifted. Concrete rings are always in a position in which it found.

- Direct ring. These products, when installation in addition are fixed with special brackets and cement mortar.

- The filtration ring. The structures are holes in a uniform distance from each other. As a result, the ground water seeps. These products are used to create a filtration sewage wells.

During mounting there are often situations when you need to adjust the volume of the structure. To narrow the internal space used by adjusting the concrete ring. They have a large width of the walls and narrowing in diameter.

Height adjustment of the manhole occurs by means of additional rings. They allow you to complete the well, without breaking norms of Standards. This is especially true when the surface of the earth is too little, and plain concrete ring is too large.

Concrete rings in this structure are at least 25 years. In some cases lifespan is 50-75 years. Very much depends on the quality of concrete and rebar, which is used in the creation of the product.

The concrete ring can be installed in acid and alkaline environment. They did not effect the formation of sludge and sewage fermentation. Better material than LCD for the creation of a septic tank not found.

The results ↑

Despite the emergence of new technologies and materials, concrete rings are still relevant. They are used in the creation of wells, and different types of external networks gas and oil pipelines. They are simple to manufacture and have long life.