Strip Foundation is often used as the basis for construction. It’s a closed circuit, resembles a reinforced concrete tape, which is installed around the perimeter of the bearing walls of the building. This Foundation optimizes the load on the base, distributing it over the entire area of the house, which increases the resistance of the building to the subsidence and prevent its distortion.

This design allows you to create a variety of buildings, including wooden houses and monolithic structure of concrete. In addition, it requires much less material and preparatory work, allowing you to save money on construction, but for quality reason, you need a good reinforcement strips, which is produced by the coherent reinforcement.

Laying and knitting reinforcement ↑

For the establishment and strengthening of strip Foundation is used by conventional rebar, held together in one structure. The main burden falls on her, which increases the lifetime of the Foundation.

To ensure that you choose the correct fittings. A suitable material with indicator K – corrosion resistant. Use the indicator C, but it is designed for connection by welding.

Before you tie rebar for the Foundation, you should select the method of connection. Often use crochet, which allows to fasten parts with normal wire. For this purpose, the three connectors:

- wire;

- plastic clip;

- plastic clamps with metal core.

Often use wire, it’s a reliable and proven option. But the plastic clamps are more convenient, faster mounted and require no tools. Their only drawback is the bad commit, but it manifests itself only when the load on the frame before pouring. After hardening of the concrete the plastic clamps are not inferior to the properties of the wire.

After the selection of valves and connector need to define the method of knitting, which depends on the tool.

Tools for knitting reinforcement on the Foundation ^ the

So how to tie rebar for the Foundation manually is quite difficult to do this, use the tools. They allow you to speed up the process and significantly improve the quality of the fixtures. A good tool will provide a quick reinforcement strip Foundation.

Among the main instruments for mating fittings are used:

- a crochet hook;

- a drill with a nozzle;

- knitting the gun;

- homemade hook.

Sometimes use plastic clamps (lugs), but they are inconvenient to work with and require a finished base. All the tools operate on the same principle, being used to «winding» wire after its knitting. Differs only knitting the gun, which itself captures the design, and tying her.

However, the strip foundations are uncomfortable to knit with it because the work area is small.

Practical and versatile option is the crochet hook. It is a professional tool for compounds that can be used anywhere. It is compact and can be used in the concrete reinforcement in the tape foundations. Homemade hook copy it, as usual hook on the handle.

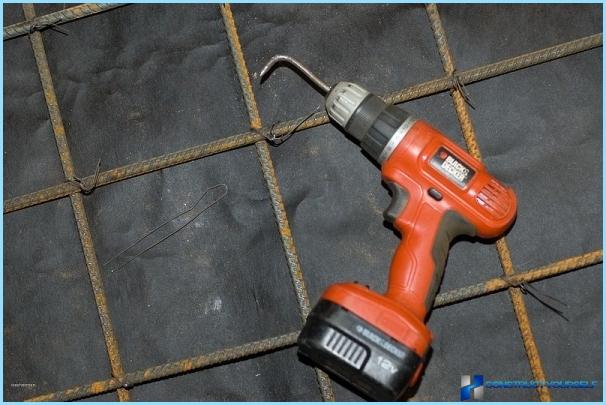

To speed up the process use a drill with a nozzle. She quickly performs a rollback of connections until it stops securely fixing design. However, if the tool is large, it will be uncomfortable when tying the ribbon frame.

The principle of operation of all instruments is similar — winding wire on the frame. Therefore, the choice depends on personal preference and does not influence the result.

The pattern of reinforcement for strip Foundation ↑

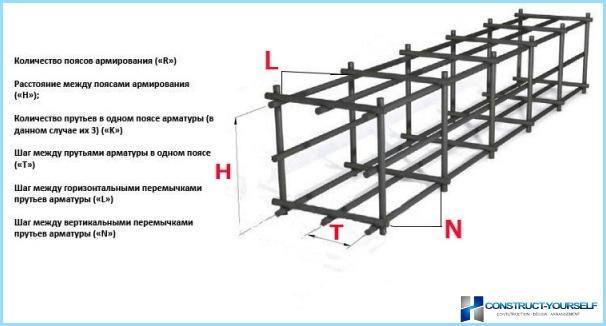

Knit reinforcing the Foundation manually is quite simple. Before that you need to properly install the frame. For this approach the following diagram of belt frame:

The number of zones of reinforcement depends on the length and height of strip Foundation. If the design is simple, the additional bars in the same zone do not exist, the schema is transformed into a cube with eight mounts in the segment. N and L are responsible for distance how to tie rebar for the Foundation. This is often 100-300 mm, depending on the load on the structure. The height of the segment do the same, and a width of about 300 millimeters. If necessary, you can add additional lines of reinforcement, as done in the picture.

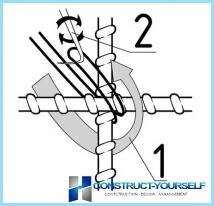

The pattern of reinforcement is simple and consists of several steps:

- take the piece of wire with a length of 25-30 cm;

- is folded in half;

- subsumed under the connecting rods one-piece side;

- loop clings to the hook and completely surrounds the rebar;

- then the free end is placed on the hook, start winding;

- the hook needs to turn clockwise until it stops;

- after the hook is removed, the connection is ready.

The path loops for mating strip Foundation can be seen in this diagram, where the marked unit steps to 5 steps, and the remaining two.

The presence of the screwdriver with a nozzle simplifies the winding wire, and knitting the gun itself carries out the whole process. With practice, speed manual winding increases as the reliability of such connections.

Other ways to connect fittings ↑

For the connection of a frame in a strip Foundation is used other ways besides mating. Clamps made of plastic that were previously mentioned, as well as welding. Their use has several advantages, but many prefer the regular wire. And there is a reason.

Clamps made of plastic — a convenient and simple way of connection design. It establishes quickly, requires no tools and is not inferior in reliability after curing of the concrete. But it has drawbacks:

- price;

- the weakness of the connections prior to pouring concrete;

- the instability of a temperature.

This connection is expensive, and its reliability is questionable prior to pouring concrete. At light load the valve may simply lead, ruining all the work before. Low temperature clamp-destructive, the connection drops with a slight frost. Therefore, it is better to use for quick and simple designs.

Do I need to tie rebar in the Foundation, when there is welding? It is a reliable connection, which only requires experience and a welding machine. It provides good mounting frame and requires the minimum of resources for independent work.

But the disadvantage of this method is the loss of strength of reinforcement. Metal under thermal influence loses its properties, which particularly affects its resistance to low temperatures. So the finished design can simply crack when the first frost. And the time spent on him a lot. So the question «to knit or to cook rebar» many prefer the first option.

How to knit plastic rebar ↑

Fibreglass — an alternative to metal in the creation of the Foundation. It has a lower cost and weight, and its lifetime are much higher. But the procedure is mating of such a framework is somewhat different from the usual.

Before knitting plastic rebar for the Foundation, need to carry out exact calculations – this is not a metal that will withstand small errors in weight and load, it needs a miscalculation and accurate weight distribution. The distance between the rods when the binding varies from 15 to 35 centimeters, in light constructions sometimes reaches 60.

To create a base always used plastic pallets (lugs) that allow the design not to sink when pouring concrete. Fiberglass reinforcement binding just used wire or clamps. It is not allowed to work without measurements, all connections should be evenly distributed on the perimeter.

Tying of the reinforcement strip Foundation is a simple process, but requires attention to each element. Dependant on structural strength and reliability of the finished Foundation. For this purpose, different tools and diagrams, but the process is quite simple. For a more detailed explanation for how to tie rebar strip Foundation, see video: