The contents

Any person who builds a new house or making repairs in the “old”, inevitably comes to the point when you need to choose and lay the floor covering. When choosing the type of coverage it is necessary to consider functional, aesthetic, financial, and mounting points. One of the best options in our conditions, is linoleum. This simple to install reliable, low maintenance and varied in decorating coating. But even for linoleum, with his feigned simplicity, you need to follow exactly the installation guidelines, so that the final result could be, if not to surpass, to meet your expectations. You need to know how to glue linoleum how to do this so that the result met or exceeded your expectations.

Linoleum – what it is ↑

The structure of the linoleum is a flexible polymeric material. Its division into separate species is just the type of raw materials used for the manufacture of:

- Linoleum on the basis of PVC. The most common polymeric material, which can be used independently, so-called single-layer linoleum, or be combined with the base. As it is foamed polymer, textile material or insulation. Any linoleum except single layer is a composite product, usually up to four layers of materials that provide excellent acoustic and thermal insulation, and durability.

- Alkyd linoleum. The basis of the linoleum are different types of alkyd resins with the addition of mineral additives. The base can be both natural and synthetic. Unlike PVC models has low elasticity and is prone to the formation and development of cracks.

- Rubber linoleum. This two-layer composite consisting of bitumen-rubber base and protective-decorative layer of colored rubber compounds. By and large, is a technical coating, which by virtue of its ductility and water-repellent properties used in industrial facilities.

- Kolloksilinovy linoleum. For manufactured using nitrocellulose. Is characterized by flexibility and a high degree of fire safety.

Any of these decks has the right to life in residential areas. The type of linoleum is determined from the ratio of its resistance to wear and dynamic loads in the room.

The types of ground underneath the linoleum and their proper preparation ↑

In construction practice, often have to deal with a concrete or wooden base (rough floor). Each of them has its own characteristics, but definitely requires preparation of surface for laying. The goal of this activity is the creation of perfectly smooth (as possible) surface. Step frankly vital, since the linoleum because of its high ductility is exactly repeat all the defects of the base.

Preparation concrete floors must begin with a diagnostic examination and measurements. Characteristic defects can be variations in height, projections, the presence of small and large shells, cracking. If their size and concentration is beyond permissible, it will have to do a forming screed. Better suited for this self-leveling mixture. Alternatively, it is possible to additionally placed on the tie sheets of plywood (of insulating reasons).

Preparation of wooden floors also requires the creation of a smooth surface. Option here are basically two:

- hand putty is any unevenness putty

- laying plywood flooring.

Preferred seems the second option, because its faster to run and in the long term it is more stable.

Proper technology placement ↑

The process of laying the polymer coating on the base should go in a strict order. This ensures a good result in the end and help avoid unnecessary spending of money and time to fix bugs.

It begins, logically, with the selection of materials, more precisely their number. The linoleum is sold in rolls, which have three basic sizes in width: 2,5; 3,4; 4 m. ideally, the width of the roll you need to choose so that it slightly overlaps the width of the room. In this case, we can exclude the need for later joining of the sheets together, which causes additional difficulties. In such a situation it will be necessary to accurately combine the two separate drawing sheets at the junction, think about how to provide safe and aesthetically acceptable connection line. Also you must understand that the entire sheet has a lot more reliability.

When determining the width of the roll it is necessary to consider the maximum width of the premises: if there is a niche or recess, they also need to be considered. Additionally, it is necessary to rely on technological margin of 5 cm on the side, which should eliminate possible irregularities of the walls. If the width of the space is greater than the maximum width of the roll and docking can not be avoided, then the best option would be to place the seam at the center of the room.

After determining the size, appearance and purchase of linoleum, he should be given time to acclimate in the room and self-lining. Considered ideal conditions, when the temperature inside does not exceed 18 degrees, and the humidity is between 40-60 %.

Classification of adhesives for linoleum ↑

The answer to the question “do I need to glue the linoleum?” obvious. He’s always under load, and if there is no appropriate fasteners, linoleum simply deformed. Laying linoleum no glue is possible at small sizes of a premise, but this is not the correct solution. In the practice of the laying of the floor covering there are two basic types of adhesive: dispersion and reaction (for joints). The choice of each of them must be justified by the type of linoleum, the foundations and the laying stage. Laying of linoleum on the adhesive should be carried out following the recommendations of the manufacturers of these materials.

Dispersion adhesive ↑

This aqueous colloidal (suspended) solution of acrylic or carboxymethylcellulose, in which add a chalk, latex, and other specialized additives. A glue for linoleum almost has no odor, it is non-toxic. But it has two major drawbacks:

- does not possess water-resistant qualities;

- when it freezes abruptly loses adhesive ability.

It is applied to linoleum on different substrate (foam, fabric, felt). The most common representatives of this group of adhesives are:

- Acrylic (acrylate). The adhesive is ideal for gluing in rooms with a moderate load on the linoleum. The very same flooring can be homogeneous and heterogeneous at their structure. The basis of the adhesive used acrylic thermoplastic resin. A striking example can serve as glue for linoleum Hamaca (Homakoll 208), «POLYNOMIAL-101» and Kiilto Extra. Has excellent adhesion;

- Bustilat. It is a group universal adhesive masses on the basis of carboxymethyl cellulose with the addition of latex and chalk. Perfect for work with a felt base sheet. These adhesives were quite common in the days of the USSR. There are a total of 4 of their kind: «Bustilat-M», «Bustilat-N», «Bustilat-D» and «Bustilat-Suite».

- Gumilaks. This group of adhesives on the basis of rubbers and latex. This is perfect if you choose the glue for linoleum, and synthetic sheets with a fabric or felt backing.

- Specialized the adhesive mass. This particular dispersion and bitumen adhesives, which are used in the presence of nonstandard conditions in the room. An example is a conductive adhesive for linoleum Forbo (FORBO Eurocol) in areas with a large concentration of electronics.

Glue for joints of linoleum ↑

This is a group of two-component adhesives on the basis of epoxy resins and polyurethanes. Its action is based on the chemical interaction of the components when connecting the grip and traction. Adhesives of this group possess remarkable plasticity and water resistance, do not have a tendency to shrink. Because of the peculiarities of reaction, these adhesives are often called cold welding, or adhesive welding of linoleum. In practice, the following types of reaction adhesives:

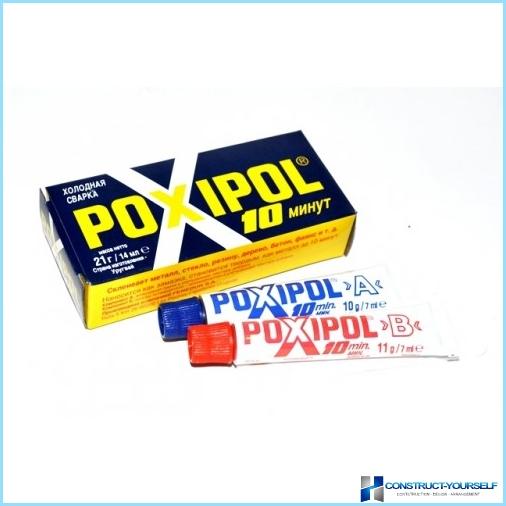

- Welding type A. Used for the treatment of joints of the sheets to create a decorative effect. An example of the glue of this group may serve as «Poxipol».

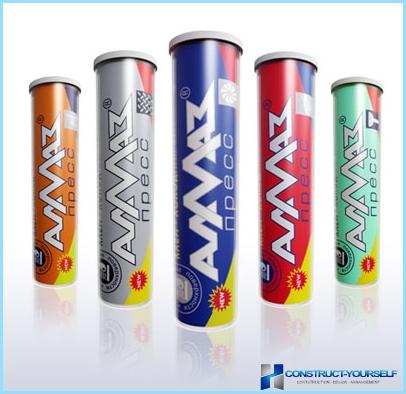

- Welding type C. perfect to secure the hard edges at the junction and eliminate the gaps. An example to serve as glue «Diamond»

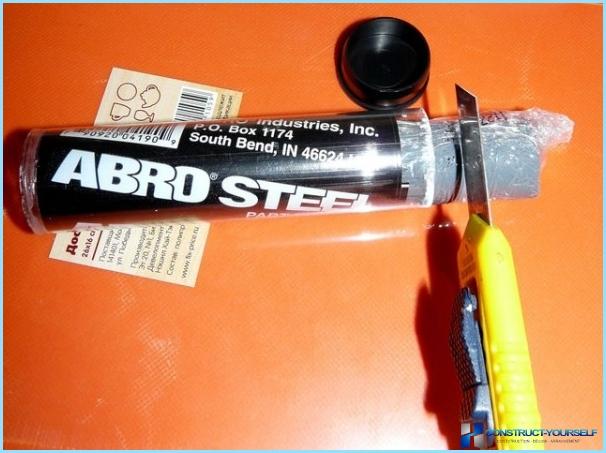

- Welding type T is Used for the treatment of joints of polyester types of linoleum. This group of adhesives concerns «Abro Steel».

The disadvantage of this glue is its Flammability, as well as the sharp smell of chemicals. Most often it is the glue for commercial linoleum with the increased loads on the flooring.

Hot joining of sheets ↑

In a situation when you need to correlate dense coatings, creating a reliable waterproof connection, resorting to the method of hot welding. To do this, at the junction fit special welded cord, which when warming up securely fuses the joints. The seam in this case is aesthetically appealing and reliable. This method is most often used in the installation of floor coverings in commercial premises.

Additional information on the bonding of linoleum you can see in the video