Linoleum refers to the long-lived in the environment of floor coverings. It is used for decades and is unlikely to in the near future will refuse such a convenient and practical way to design floors. To extend the period of use, while maintaining an attractive appearance and quality, will help correct glue joints.

The types of adhesives ↑

Possession of information about the properties of adhesives contributes to the correct selection in accordance with the structure of the flooring and its purpose. Range of specialized glue for linoleum is divided into 2 types – dispersion and reaction. The first group recommended for use when docking:

- linoleum on a fabric basis;

- PVC coating;

- natural material;

- vinyl coating.

Main area of application of the reaction adhesive bonding of commercial linoleum.

Dispersion adhesive ↑

The aqueous dispersion adhesive composition includes cellulosimicrobium acid or acrylic additive in the form of chalk and latex. Its elastic properties are indispensable for the bonding of linoleum, the absence of toxic emissions and environmental safety is another advantage of the material. Dispersion adhesive is divided into groups:

- Acrylate adhesive contains thermoplastic resin, gives a composition of increased viscosity. Recommended for homogeneous and heterogeneous linoleum with a base of fibre, jute or double synthetic base. The composition is suitable for bonding linoleum in areas with medium and high traffic, are best suited for hallway and kitchen. Has high adhesion on absorbent grounds.

- Bustilat belongs to a universal type of adhesives are made using latex, chalk and karboksimetilcelljulozy substances. This option is most acceptable to glue the linoleum on the junction of the pile based.

- The structure of gumilaks contains a mix of rubber and latex. Field of application bonding of linoleum or synthetic surfaces with felt and fabric base.

- Bitumen mastic is recommended to glue the linoleum with fabric.

In addition to the advantages before you glue the linoleum between them, you should consider the shortcomings of the product. After freezing and in high humidity conditions the properties of the dispersion adhesive is lost without possibility of recovery. At low temperatures, the composition crumbles and does not have the elasticity, high humidity will trigger the peeling linoleum. To preserve the quality of the glued joint the room temperature should not fall below 15onC, and the humidity level not to exceed 60%.

The reaction adhesive ↑

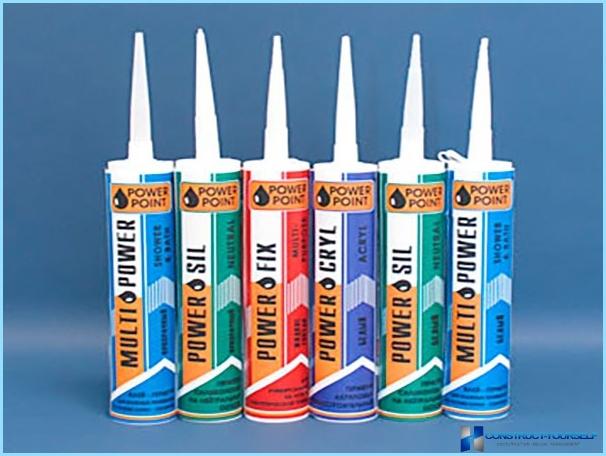

The basis of the reaction adhesive comprises epoxy and polyurethane compounds. It has high adhesion properties when interacting with different materials. The elements stick together at the expense of the process of the chemical reaction of two-component composition, called cold welding. Significant disadvantages are the pungent smell and the danger of ignition. The reaction adhesive is represented by two types:

- universal composition, has a low moisture resistance;

- moisture-proof form, does not lose its properties in areas with high humidity levels.

To glue the seams for commercial linoleum is one of the functions of the reaction adhesive.

Cold welding ↑

Operation of linoleum for a long period is impossible without high-quality fasteners. One of the ways to glue the seams of the linoleum cold welding. What is the essence of this method? The use of a special adhesive having the properties of the solvent, provides the transformation of the edges of the floor covering in the liquid state. After connecting webs and evaporation of the adhesive composition is formed connection high strength with attractive appearance. The technology of cold welding eliminates the use of hot air in the processing of linoleum. The end result is not inferior to the quality of the weld, if the linoleum is glued with hot welding. This method is indispensable for surfaces in domestic premises and when connecting complex configuration seams.

Options bonding ↑

Glue the linoleum, you can apply glue three types – A, C, and So the choice depends on the period of operation of the floor covering and your professional skills.

- In case, if you glue the linoleum is required immediately after installation, apply adhesive type A, designed for welding the newly laid product. This is the most common method. The structure of the new linoleum is still soft and adhesive type is sufficient liquid. This combination, together with a properly stacked material contributes to a virtually invisible seam, especially when you have successfully matched the pattern.

- To connect the previously laid coating recommend the second method. In this case, open seams, better glue cold welding with the use of a composition With type. The difference is the consistency of glue, it is much thicker. Filling your ground voids, the glue type makes a new seam coating, preventing the likelihood of divergence of the edges in the future. In this case, the use of tape to protect the edges of linoleum is unreasonable, as the viscous consistency of the glue is not able to spread and damage the edges when gluing.

- Much less resort to cold welding and adhesive application T-type. Its purpose is to glue the parts of the coating of PVC based on polyester. Excessive toxicity and the complexity of the operation allows the use of a composition of the type only professionals.

Features of the process ↑

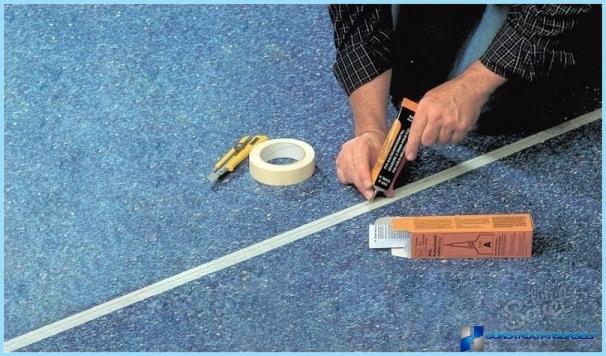

In order to glue the joints of linoleum between them, you need to prepare everything in advance. The minimum clearance on a new coating is formed by applying products overlap with a margin of 5 cm is marked using a pencil and ruler, cut is the Wallpaper with a knife. Glue obtained in this way the joint will not be difficult. Another caveat before gluing the joints, the total consolidation of the coating. With floor space of more than 20 mTwo this is a must. The final preparatory stage – cleaning of the seam from dirt and dust. Dry and clean surface – good result.

The main task – to glue the linoleum unnoticed. In connection with the ability of the adhesive to act in the form of a solvent, care should be taken to protect their hands and the surface of the treated material. Rubber gloves solve the problem of their own security, for linoleum prepare unilateral masking tape. It can be sticked separately on each part of the coating or in the middle of the weld with subsequent cutting.

When you perform cold welding, consider the presence of «needle» on the tip. In case of contact with the adhesive on the linoleum, use to remove with a cotton swab. When applying follow a uniform layer over the entire length of the seam, maintain a height of 4 mm. to Glue linoleum is available in two ways. The first option involves the application of the glue at the same time on two parts of the material. Trapped in the seam, the glue interacts with the coating and the process of polymerization. In the second case the substance is applied alternately on each part of the coating with the further accession to the floor. After laying linoleum carefully smooth, achieving high-quality bonding of the seams. The latest version is unacceptable in the case of pre-gluing of linoleum on the floor.

The bonding step completes the removal of excess glue. To rush that process, it can provoke separation of the mixture from the coating. Cold welding fresh has the ability to bounce, and if after cutting it to pull the subsequently formed recess. Consequently, it is better to divide into two stages, the more well-cured adhesive can be cut easier.

Hot welding ↑

Apply hot welding is recommended in rooms with high load to glue the joints of commercial linoleum. Requires use of special equipment in the form of welding bottles and welding rods of plasticized polyvinyl chloride. An important condition is that the skills of the performers. To correctly glue the linoleum hot welding after the fixation of the material on the floor surface, so it works best to organize the next day after gluing.

First, on adjacent panels under the bars are cut grooves are V-shaped. In the process of hot welding torch with the welding rod along the seam is carried out. Softened from the hot air stream the surface of the linoleum is glued under the action of the pressure roller. Exposed edge of the seam cooled down a bit curved handled knife or flat chisel. Then the joint is polished before formation of a smooth surface.

Strict adherence to guidelines will allow you to easily glue the linoleum in the home, in the end, getting a quality result.