The contents

- Linoleum is made of natural components

- Linoleum from PVC (polyvinyl chloride)

- Linoleum, rubber, or relin

- Nitrocellulose linoleum (kalokerinos)

- Alkyd linoleum (heffley)

Linoleum is a very long time has won popularity in the domestic market. He continues to hold its leading position and today. Such popularity is understandable, because it is quite easy to installation, high wear resistance, provides a choice of a huge number of textures and colors and reasonable price.

«Pros» and «cons» ↑

The advantages of the material include:

- The ease of installation. This is one of the main «pros» this floor covering. Indeed, thanks to him buyer can save some more money and lay his own.

- Simplicity of maintenance. Traces of dirt on the considered floor covering are less noticeable than on the parquet or laminate, and even in the case of their appearance they are easily removed by wet cleaning.

- High moisture resistance and resistance to acidic environment. Because of this property, the linoleum can be installed in areas where there is high humidity, but also to wipe it as often as necessary.

- High levels of insulation.

- Low acoustic permeability.

- No need for coating with an additional layer of protection.

- Elasticity and effect of slip, which ensures safe operation. Especially important is this factor in the presence of the flat children.

- The widest selection of textures and colors. This gives you the opportunity to realize even the most unique design ideas.

Disadvantages include:

- The production uses harmful chemicals, but in General it complies with all the established sanitary norms and rules.

- During a long stay in the same place heavy objects can cause dents.

Types of linoleum ↑

There are several classifications of the considered floor covering. Let us consider each of them.

The classification based on materials ↑

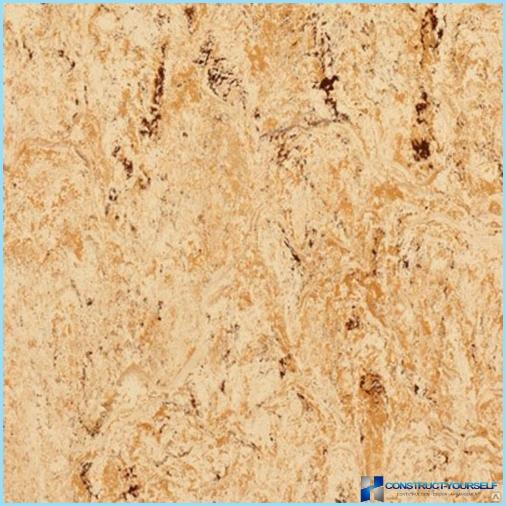

Linoleum is made from natural components ↑

For its production used:

- lime;

- wood resin;

- oil from flax;

- cork flour.

This species is most environmentally friendly and safe for health. It is resistant to the effects of bacteria and has anti-static properties, does not absorb fat as well as hard to fire it up.

Linoleum from PVC (polyvinyl chloride) ↑

This type can be produced on the fabric, netchannel thermal insulation or foam based. In its structure it is monolayer or multilayer. The main drawback — the presence of a sharp odor, which disappears long enough, and large shrinkage.

Linoleum, rubber, or relin ↑

It consists of 2 layers. The basis of it is bitumen or rubber, which was already in use. The outer layer is made from synthetic rubber, specific fillers and dyes. This form is very ductile and has good resistance to exposure to high humidity.

Nitrocellulose linoleum (kalokerinos) ↑

It is a thin coating made from nitrocellulose. Has a beautiful glossy Shine, very elastic and resistant to moisture. Main «minus» is the increased fire hazard.

Alkyd linoleum (heffley) ↑

Consists of fabric material, alkyd resin, dyes. Has excellent sound insulation properties, but at the same time is quite a fragile material.

Classification based on the structure of the material ↑

Basically ↑

This species has heat-insulating fabric or non-woven substrate. Very elastic, perfectly fits on any surface.

Unbonded ↑

This coating is sufficiently thin. Its thickness is from one half to three millimeters. Laying of the linoleum can only be done on a perfectly smooth surface. It is a cheap material having a short lifetime.

Homogeneous ↑

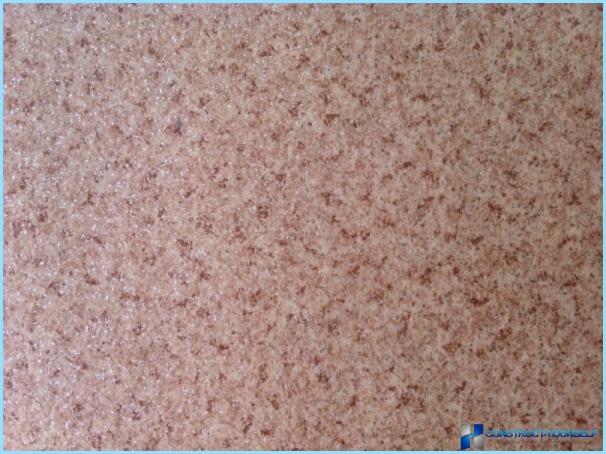

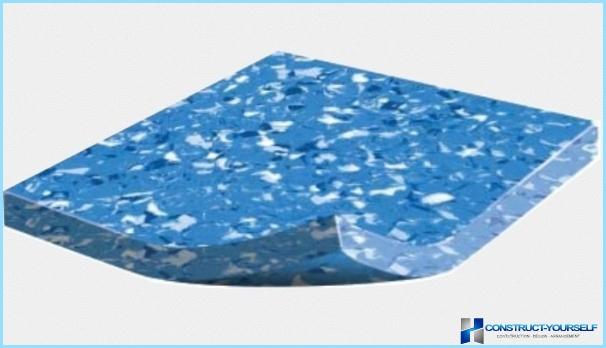

Has a homogeneous structure. Consists of a mixture of granules of polyvinyl chloride and pigments. The picture is not on the top layer and penetrates the entire material. Homogeneous linoleum is ideal for installation in rooms with high passability, as it is very resistant to abrasion.

Heterogeneous ↑

You can have up to six layers. The basis of it is fiberglass. The substrate may be foamed, woven or nonwoven.

Classification based on scope ↑

Choosing flooring, you should know that it is divided into classes. So, in Europe there are 21-23, 31-34, 41-43 classes of linoleum. They differ not only in appearance but also the technical properties. According to local standards linoleum is divided into three types depending on the location of use, and each type is subdivided into classes. With classes of linoleum and their description you can see in the table below.

Thus, depending on the application there are:

Household ↑

Used for laying in premises intended for human habitation. Has a wide selection of colors and décor. Most often, it is a heterogeneous coating having protective outer layer from 0.15 to 0.3 mm. This species has a low durability unlike commercial counterparts, but is more environmentally friendly.

Semi-commercial ↑

Used under conditions of average permeability (cafes, shops, offices). The characteristics inherent in him, he is between household and commercial.

Commercial ↑

Placed in areas with high traffic (manufacturing, large stores or offices). Can be as heterogeneous and homogeneous. The protective layer is about 0.8 millimeters and often has in its composition additives (insulators, antistatic agents, and possibly corundum). Has a high abrasion resistance and keeps its original appearance for a long time.

Linoleum stamps OL, W, M, TTN ↑

For installation in the most suitable apartment is linoleum, which has the following marking PR, W, M, TTN. Let’s see what they mean.

Linoleum PR ↑

The marking of PR means that linoleum was produced promagnum method. From manufacturers this method is the most common. This is due to its simplicity and low cost. Floor covering, made promagnum way, meets all established standards.

The method of manufacture there are also such types of linoleum as:

- VC, or roller-calender;

- PRP, or contact promisei;

- EK, or extrusion;

- EKP, or extrusion, having a top transparent PVC film.

Linoleum W ↑

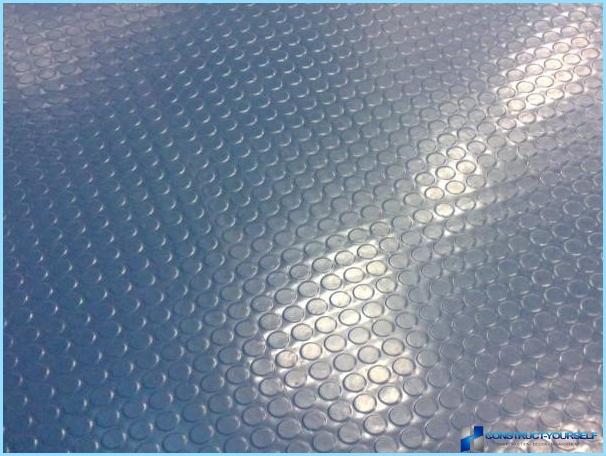

Marking of W, so that the coating has the needle-punched surface, consisting of a mixture of synthetic and recycled fibers with top protective cover made of polyester and other synthetic fibers, to prevent decay of the underlying cause. Also, depending on the material used for the underlay, there are:

- VTK — the underlying cause is the same as W, but has the frame;

- With the subbase consists of artificial fibers;

- X — subbase also antiseptic, but consists of synthetic fibers.

- D (L) is the underlying cause antiseptirovannoe, consisting of bast fibres or of jute.

Linoleum M ↑

«M» means that it is monochrome or marbled linoleum that has multiple layers. In addition, the number of layers of linoleum may be:

- MP – multi-layer-coated transparent PVC film having a pattern;

- On — one-layer, solid or marble color.

Linoleum TTN ↑

It’s baseless, flame-resistant PVC coating. It is made of roller-calender method according to the formula approved by the customer. It is divided into TTN-1 TTN-2. The latter has a high durability.

Tips for choosing linoleum ↑

When buying linoleum, it is necessary to take into account the permeability of the room, its humidity level and temperature.

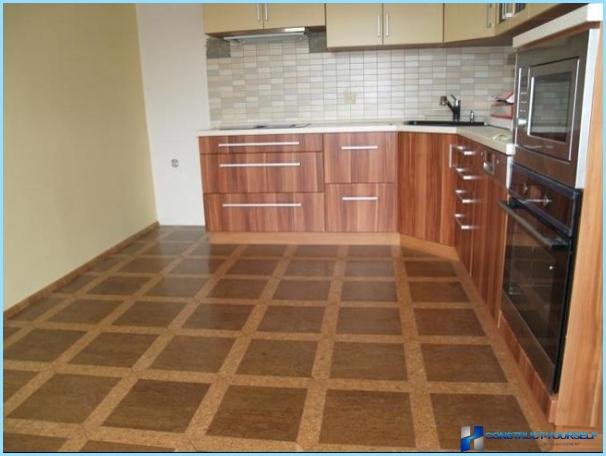

- The areas with the greatest cross-country are corridor, hall and kitchen. Moreover, wet cleaning is often enough. Therefore, for these rooms, you can use linoleum, with a total thickness equal to three or four millimeters, and the top protective coating greater than 0.25 mm.

- For the bedroom and the living room will cover household-type thickness from half to two millimeters and a protective film of 0.1–0.2 mm.

- In the bathrooms and a bath you can use a single layer of a synthetic variant, having a thickness of 1.5–1.6 mm.

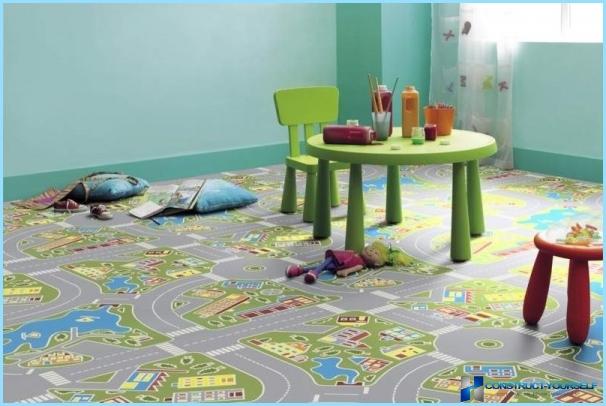

- For a child’s room is to choose the floor made of natural materials. Its thickness should be 3 mm or more.

Also to help with the selection of linoleum for each room of your apartment will be able to view the below video: